Page 37 - MetalForming January 2016

P. 37

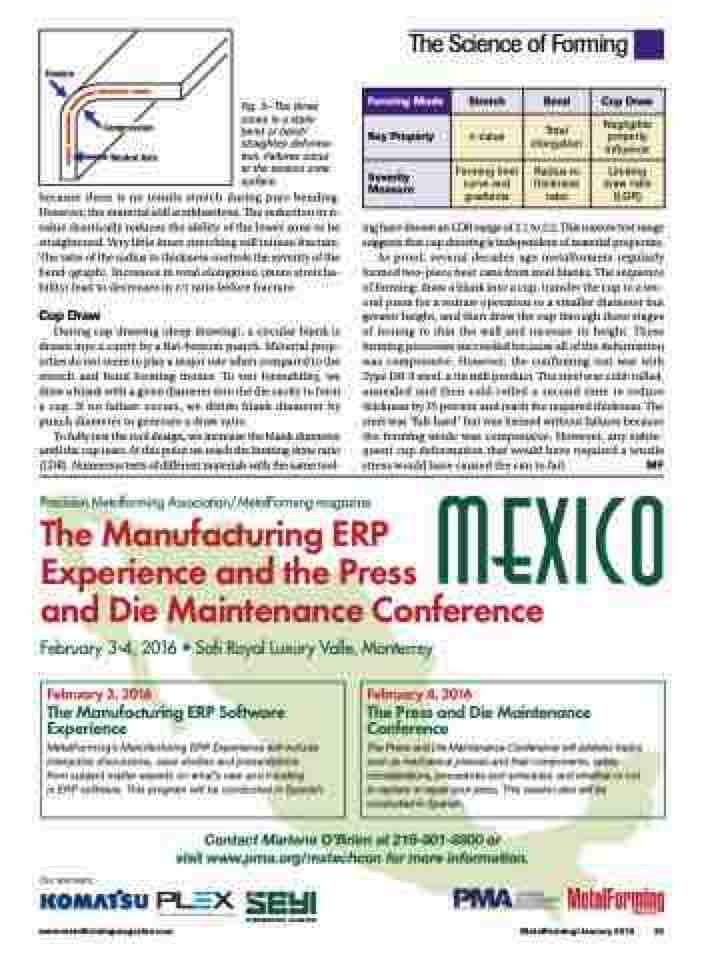

Tension

Compression Neutral Axis

Fig. 3—The three zones in a static bend or bend/ straighten deforma- tion. Failures occur at the tension zone surface.

because there is no tensile stretch during pure bending. However, the material still workhardens. The reduction in n- value drastically reduces the ability of the lower zone to be straightened. Very little inner stretching will initiate fracture. The ratio of the radius to thickness controls the severity of the bend (graph). Increases in total elongation (more stretcha- bility) lead to decreases in r/t ratio before fracture.

Cup Draw

During cup drawing (deep drawing), a circular blank is drawn into a cavity by a flat-bottom punch. Material prop- erties do not seem to play a major role when compared to the stretch and bend forming modes. To test formability, we draw a blank with a given diameter into the die cavity to form a cup. If no failure occurs, we divide blank diameter by punch diameter to generate a draw ratio.

To fully test the tool design, we increase the blank diameter until the cup tears. At this point we reach the limiting draw ratio (LDR). Numerous tests of different materials with the same tool-

ing have shown an LDR range of 2.1 to 2.2. This narrow test range suggests that cup drawing is independent of material properties. As proof, several decades ago metalformers regularly formed two-piece beer cans from steel blanks. The sequence of forming: draw a blank into a cup, transfer the cup to a sec- ond press for a redraw operation to a smaller diameter but greater height, and then draw the cup through three stages of ironing to thin the wall and increase its height. These forming processes succeeded because all of the deformation was compressive. However, the confirming test was with Type DR-9 steel, a tin mill product. The steel was cold-rolled, annealed and then cold-rolled a second time to reduce thickness by 35 percent and reach the required thickness. The steel was “full-hard” but was formed without failures because the forming mode was compressive. However, any subse- quent cup deformation that would have required a tensile stress would have caused the can to fail. MF

The Science of Forming

Forming Mode

Stretch

Bend

Cup Draw

Key Property

n-value

Total elongation

Negligible property influence

Severity Measure

Forming limit curve and gradients

Radius to thickness ratio

Limiting draw ratio (LDR)

Precision Metalforming Association/MetalForming magazine

The Manufacturing ERP

Experience and the Press

and Die Maintenance Conference

February 3-4, 2016 • Safi Royal Luxury Valle, Monterrey

February 4, 2016

The Press and Die Maintenance

Conference

The Press and Die Maintenance Conference will address topics such as mechanical presses and their components, safety considerations, procedures and schedules, and whether or not to replace or repair your press. This session also will be conducted in Spanish.

February 3, 2016

The Manufacturing ERP Software Experience

MetalForming’s Manufacturing ERP Experience will include interactive discussions, case studies and presentations

from subject matter experts on what’s new and trending

in ERP software. This program will be conducted in Spanish.

Contact Marlene O’Brien at 216-901-8800 or visit www.pma.org/mxtechcon for more information.

Our sponsors:

www.metalformingmagazine.com MetalForming/January 2016 35