Page 35 - MetalForming January 2016

P. 35

Table 1—Change in Deformation Based on Yield Strength

V-die opening, in.

Depth for Δ = 1 deg., in.

1⁄4

0.016

3⁄8

0.024

1⁄2

0.027

Table 2—Thickness Variations

Category

A1

A

B

C

D

Tolerance (in.)

± 0.0055

± 0.0075

± 0.0087

± 0.010

± 0.011

in production techniques. To avoid the risk of building weak structures, regu- lations require a declaration of the min- imum yield strength. So, any steel with a yield strength greater than 36,000 psi will be labeled as A36.

As a result, 41,000-psi steel still will be sold as A36, in spite of being 13 per- cent harder. The increased resistance will impart a higher force on the press brake, which will cause the ram to bow even more. For instance, switching from a 36,000- to a 41,000-psi steel will result in a deformation difference of roughly 0.002 in. in depth. Yet, this small curve causes a change of nearly 1 deg. in a 0.3-in. V-die (Table 1).

In other words, a thickness of less than that of a single sheet of paper (less than 0.04 in.) causes remarkable differ- ences. Bear in mind that narrow open- ings such as these often are used to bend thin sheet for high-quality products.

2) Holes Wreak Havoc

Label data on the steel we buy, which may or may not be reliable in the first place, become completely worth- less when we modify the sheet. Holes change strength along the bending line, whether the holes are produced via thermal cut or by drilling or milling. The same is true if the same piece has bends. In addition, punched holes introduce internal stresses that make it even more difficult to consider crown- ing as a fixed amount of deformation.

3) Conditions Matter

Steel is a living thing. Rolling direc- tions create fibers in the structure, so bending across or along the grain will affect both the required bending force and the springback.

A recently pickled sheet is harder than an aged or oxidized sheet, even

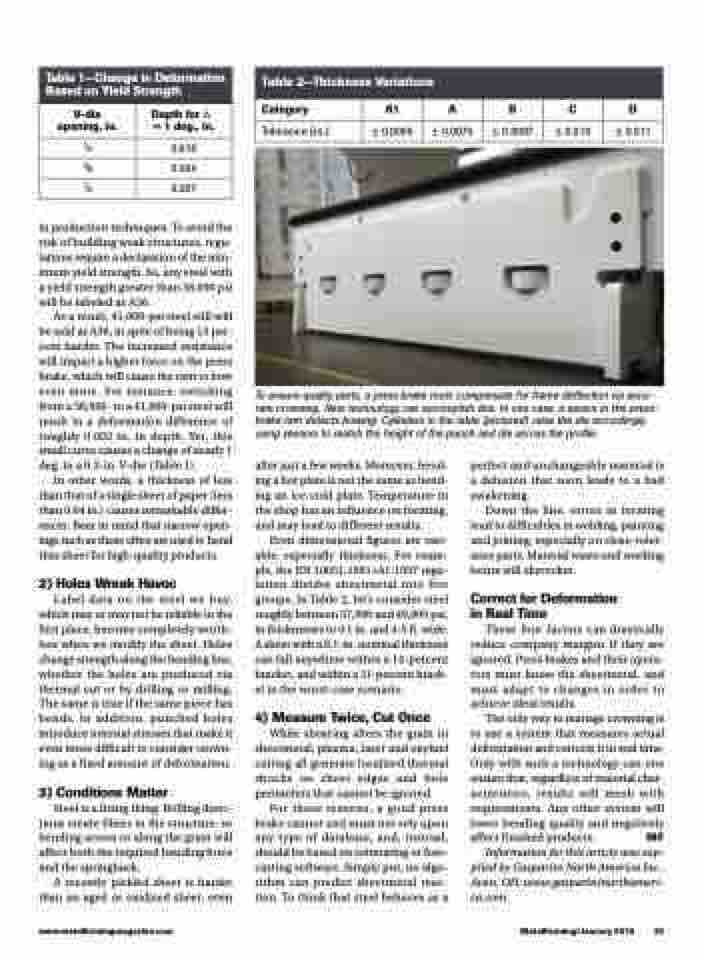

To ensure quality parts, a press brake must compensate for frame deflection via accu- rate crowning. New technology can accomplish this. In one case, a sensor in the press- brake ram detects bowing. Cylinders in the table (pictured) raise the die accordingly, using sensors to match the height of the punch and die across the profile.

www.metalformingmagazine.com

MetalForming/January 2016 33

after just a few weeks. Moreover, bend- ing a hot plate is not the same as bend- ing an ice-cold plate. Temperature in the shop has an influence on forming, and may lead to different results.

Even dimensional figures are vari- able, especially thickness. For exam- ple, the EN 10051:1991+A1:1997 regu- lation divides sheetmetal into five groups. In Table 2, let’s consider steel roughly between 37,000 and 49,000 psi, in thicknesses to 0.1 in. and 4-5 ft. wide. A sheet with a 0.1-in. nominal thickness can fall anywhere within a 14-percent bracket, and within a 31-percent brack- et in the worst-case scenario.

4) Measure Twice, Cut Once

While shearing alters the grain in sheetmetal, plasma, laser and oxyfuel cutting all generate localized thermal shocks on sheet edges and hole perimeters that cannot be ignored.

For these reasons, a good press brake cannot and must not rely upon any type of database, and, instead, should be based on estimating or fore- casting software. Simply put, no algo- rithm can predict sheetmetal reac- tion. To think that steel behaves as a

perfect and unchangeable material is a delusion that soon leads to a bad awakening.

Down the line, errors in forming lead to difficulties in welding, painting and joining, especially on close-toler- ance parts. Material waste and working hours will skyrocket.

Correct for Deformation in Real Time

These four factors can drastically reduce company margins if they are ignored. Press brakes and their opera- tors must know the sheetmetal, and must adapt to changes in order to achieve ideal results.

The only way to manage crowning is to use a system that measures actual deformation and corrects it in real time. Only with such a technology can one ensure that, regardless of material char- acteristics, results will mesh with requirements. Any other system will lower bending quality and negatively affect finished products. MF

Information for this article was sup- plied by Gasparini North America Inc., Avon, OH; www.gasparininorthameri- ca.com.