Page 34 - MetalForming January 2016

P. 34

The Four Characteristics of Sheetmetal

In press brakes, crowning compensates

for frame deformation. Manage crowning by knowing your steel and employing robust estimating and forecasting software.

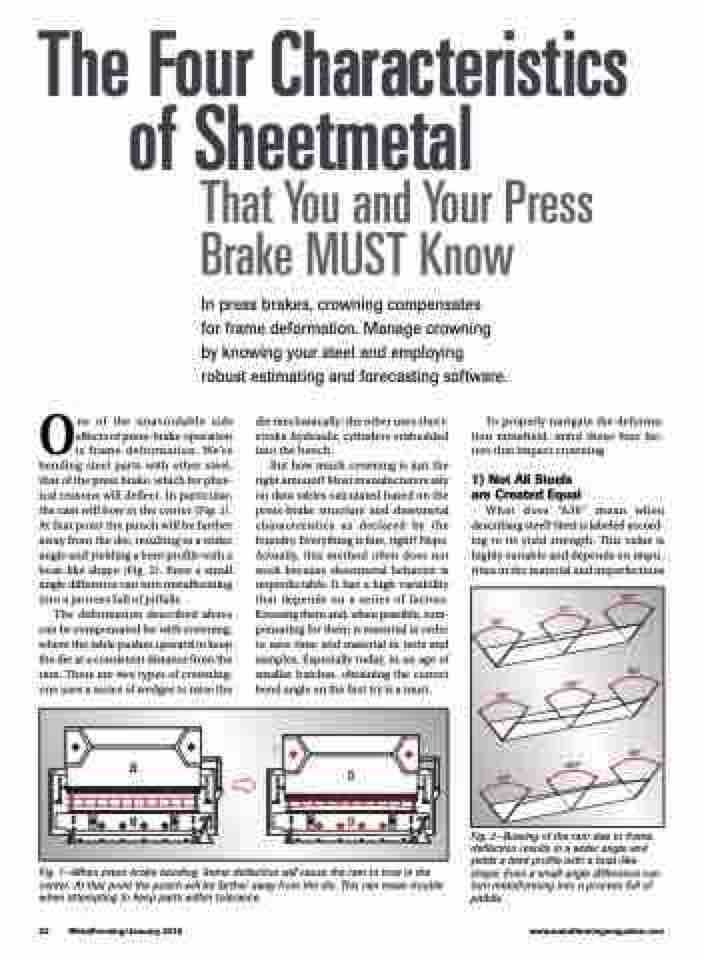

One of the unavoidable side effects of press-brake operation is frame deformation. We’re bending steel parts with other steel, that of the press brake, which for phys- ical reasons will deflect. In particular, the ram will bow in the center (Fig. 1). At that point the punch will be farther away from the die, resulting in a wider angle and yielding a bent profile with a boat-like shape (Fig. 2). Even a small angle difference can turn metalforming into a process full of pitfalls.

The deformation described above can be compensated for with crowning, where the table pushes upward to keep the die at a consistent distance from the ram. There are two types of crowning: one uses a series of wedges to raise the

die mechanically; the other uses short- stroke hydraulic cylinders embedded into the bench.

But how much crowning is just the right amount? Most manufacturers rely on data tables calculated based on the press-brake structure and sheetmetal characteristics as declared by the foundry. Everything is fine, right? Nope. Actually, this method often does not work because sheetmetal behavior is unpredictable. It has a high variability that depends on a series of factors. Knowing them and, when possible, com- pensating for them is essential in order to save time and material in tests and samples. Especially today, in an age of smaller batches, obtaining the correct bend angle on the first try is a must.

To properly navigate the deforma- tion minefield, mind these four fac- tors that impact crowning.

1) Not All Steels are Created Equal

What does “A36” mean when describing steel? Steel is labeled accord- ing to its yield strength. This value is highly variable and depends on impu- rities in the material and imperfections

90°

90°

90°

90°

>90°

<90°

90°

90°

90°

Fig. 1—When press-brake bending, frame deflection will cause the ram to bow in the center. At that point the punch will be farther away from the die. This can mean trouble when attempting to keep parts within tolerance.

Fig. 2—Bowing of the ram due to frame deflection results in a wider angle and yields a bent profile with a boat-like shape. Even a small angle difference can turn metalforming into a process full of pitfalls.

32 MetalForming/January 2016

www.metalformingmagazine.com