Page 28 - MetalForming January 2015

P. 28

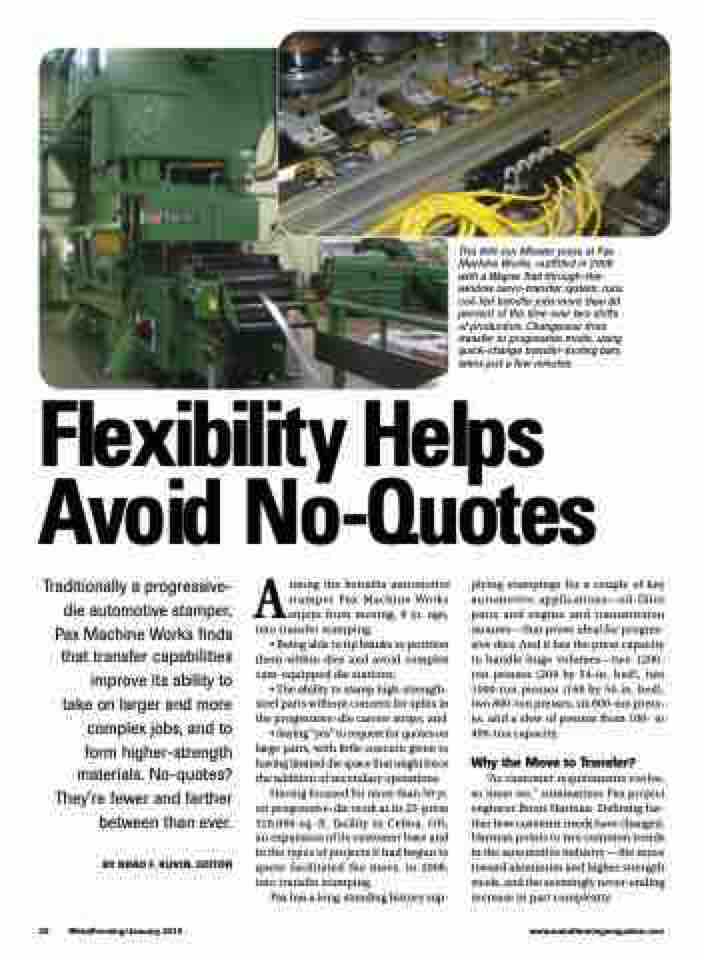

This 800-ton Minster press at Pax Machine Works, outfitted in 2008 with a Wayne Trail through-the- window servo-transfer system, runs coil-fed transfer jobs more than 80 percent of the time over two shifts of production. Changeover from transfer to progressive mode, using quick-change transfer-tooling bars, takes just a few minutes.

Flexibility Helps Avoid No-Quotes

Traditionally a progressive- die automotive stamper, Pax Machine Works finds that transfer capabilities improve its ability to take on larger and more complex jobs, and to form higher-strength materials. No-quotes? They’re fewer and farther between than ever.

BY BRAD F. KUVIN, EDITOR

Among the benefits automotive stamper Pax Machine Works enjoys from moving, 6 yr. ago, into transfer stamping:

• Being able to tip blanks to position them within dies and avoid complex cam-equipped die stations;

• The ability to stamp high-strength- steel parts without concern for splits in the progressive-die carrier strips; and

• Saying “yes” to request for quotes on large parts, with little concern given to having limited die space that might force the addition of secondary operations.

Having focused for more than 50 yr. on progressive-die work at its 23-press 326,000-sq.-ft. facility in Celina, OH, an expansion of its customer base and in the types of projects it had begun to quote facilitated the move, in 2008, into transfer stamping.

Pax has a long-standing history sup-

plying stampings for a couple of key automotive applications—oil-filter parts and engine and transmission mounts—that prove ideal for progres- sive dies. And it has the press capacity to handle huge volumes—two 1200- ton presses (204 by 54-in. bed), two 1000-ton presses (168 by 54-in. bed), two 800-ton presses, six 600-ton press- es, and a slew of presses from 100- to 400-ton capacity.

Why the Move to Transfer?

“As customer requirements evolve, so must we,” summarizes Pax project engineer Brent Harman. Defining fur- ther how customer needs have changed, Harman points to two common trends in the automotive industry —the move toward aluminum and higher strength steels, and the seemingly never-ending increase in part complexity.

26

MetalForming/January 2015

www.metalformingmagazine.com