Page 29 - MetalForming January 2015

P. 29

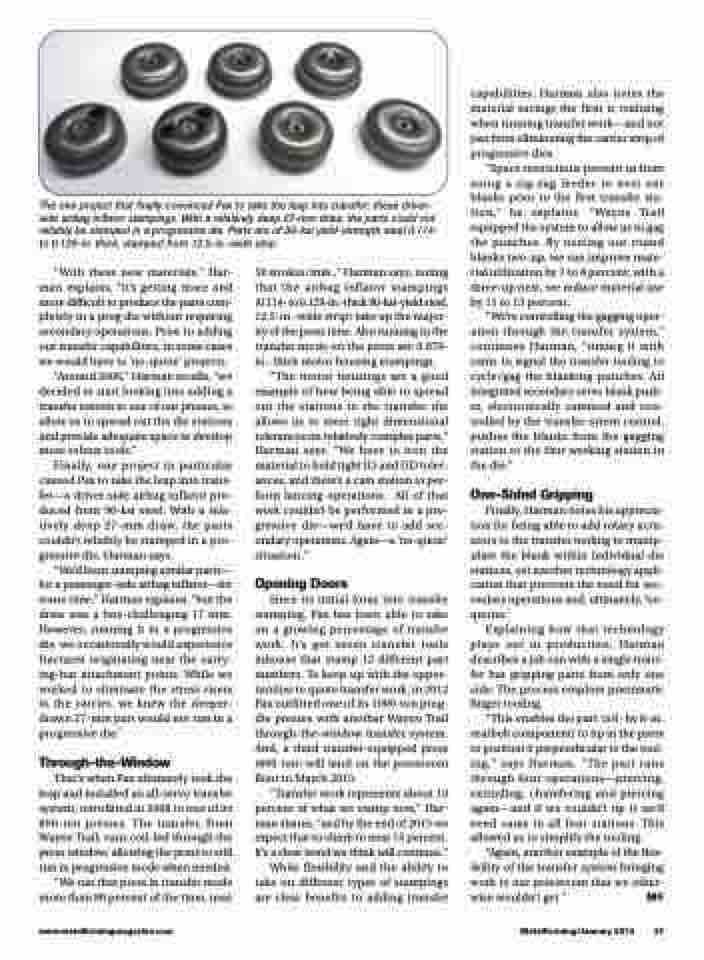

The one project that finally convinced Pax to take the leap into transfer: these driver- side airbag inflator stampings. With a relatively deep 27-mm draw, the parts could not reliably be stamped in a progressive die. Parts are of 90-ksi yield-strength steel 0.114- to 0.129-in. thick, stamped from 12.5-in.-wide strip.

capabilities, Harman also notes the material savings the firm is realizing when running transfer work—and not just from eliminating the carrier strip of progressive dies.

“Space restrictions prevent us from using a zig-zag feeder to nest our blanks prior to the first transfer sta- tion,” he explains. “Wayne Trail equipped the system to allow us to gag the punches. By nesting our round blanks two-up, we can improve mate- rial utilization by 7 to 8 percent; with a three-up nest, we reduce material use by 11 to 13 percent.

“We’re controlling the gagging oper- ation through the transfer system,” continues Harman, “timing it with cams to signal the transfer tooling to cycle/gag the blanking punches. An integrated secondary servo blank push- er, electronically cammed and con- trolled by the transfer-sytem control, pushes the blanks from the gagging station to the first working station in the die.”

One-Sided Gripping

Finally, Harman notes his apprecia- tion for being able to add rotary actu- ators to the transfer tooling to manip- ulate the blank within individual die stations, yet another technology appli- cation that prevents the need for sec- ondary operations and, ultimately, ‘no- quotes.’

Explaining how that technology plays out in production, Harman describes a job run with a single trans- fer bar gripping parts from only one side. The process employs pneumatic finger tooling.

“This enables the part (a 6- by 8-in. seatbelt component) to tip in the press to position it perpendicular to the tool- ing,” says Harman. “The part runs through four operations—piercing, extruding, chamfering and piercing again—and if we couldn’t tip it we’d need cams in all four stations. This allowed us to simplify the tooling.

“Again, another example of the flex- ibility of the transfer system bringing work to our pressroom that we other- wise wouldn’t get.” MF

“With these new materials,” Har- man explains, “it’s getting more and more difficult to produce the parts com- pletely in a prog die without requiring secondary operations. Prior to adding our transfer capabilities, in some cases we would have to ‘no-quote’ projects.

“Around 2006,” Harman recalls, “we decided to start looking into adding a transfer system to one of our presses, to allow us to spread out the die stations and provide adequate space to develop more robust tools.”

Finally, one project in particular caused Pax to take the leap into trans- fer—a driver-side airbag inflator pro- duced from 90-ksi steel. With a rela- tively deep 27-mm draw, the parts couldn’t reliably be stamped in a pro- gressive die, Harman says.

“We’d been stamping similar parts— for a passenger-side airbag inflator—for some time,” Harman explains, “but the draw was a less-challenging 17 mm. However, running it in a progressive die, we occasionally would experience fractures originating near the carry- ing-bar attachment points. While we worked to eliminate the stress risers in the carrier, we knew the deeper- drawn 27-mm part would not run in a progressive die.”

Through-the-Window

That’s when Pax ultimately took the leap and installed an all-servo transfer system, retrofitted in 2008 to one of its 800-ton presses. The transfer, from Wayne Trail, runs coil-fed through the press window, allowing the press to still run in progressive mode when needed.

“We run that press in transfer mode more than 80 percent of the time, near

50 strokes/min.,” Harman says, noting that the airbag inflator stampings (0.114- to 0.129-in.-thick 90-ksi-yield steel, 12.5-in.-wide strip) take up the major- ity of the press time. Also running in the transfer mode on the press are 0.079- in.-thick motor housing stampings.

“The motor housings are a good example of how being able to spread out the stations in the transfer die allows us to meet tight dimensional tolerances on relatively complex parts,” Harman says. “We have to iron the material to hold tight ID and OD toler- ances, and there’s a cam station to per- form lancing operations. All of that work couldn’t be performed in a pro- gressive die—we’d have to add sec- ondary operations. Again—a ‘no-quote’ situation.”

Opening Doors

Since its initial foray into transfer stamping, Pax has been able to take on a growing percentage of transfer work. It’s got seven transfer tools inhouse that stamp 12 different part numbers. To keep up with the oppor- tunities to quote transfer work, in 2012 Pax outfitted one of its 1000-ton prog- die presses with another Wayne Trail through-the-window transfer system. And, a third transfer-equipped press (600 ton) will land on the pressroom floor in March 2015.

“Transfer work represents about 10 percent of what we stamp now,” Har- man shares, “and by the end of 2015 we expect that to climb to near 15 percent. It’s a clear trend we think will continue.”

While flexibility and the ability to take on different types of stampings are clear benefits to adding transfer

www.metalformingmagazine.com

MetalForming/January 2015 27