Page 40 - MetalForming December 2014

P. 40

Tooling by Design

By Peter Ulintz

Monkey Business

Irecently read online about a sociology experiment con- ducted during the 1960s. Scientists placed five monkeys in a cage, with a bunch of bananas hung from the ceiling and a ladder placed directly beneath. It took only a few sec- onds for one of the monkeys to race up the ladder to grab the bananas.

The next day, whenever any of the monkeys started up the ladder, the researchers would spray all of them with cold water. Soon, each of the monkeys learned to not climb the ladder. And, if any of them started to climb, the others would hold them back by pulling on their tails. This was done repeatedly until each monkey had learned the lesson: Don’t climb the ladder.

Once all five monkeys were conditioned to avoid the lad- der, the researchers substituted in a new monkey. And, of course, when the “new guy” spotted the bananas and start- ed up the ladder, the other four monkeys jumped in and pre- vented him from climbing.

One by one the researchers replaced each monkey until none of the monkeys in the cage had been sprayed by the icy water. Yet none of these new monkeys would go up the lad- der. The rules had been set.

The monkeys were, in effect, saying, “That’s just the way we do things around here.” Sound familiar? Many organiza- tions, including press shops and machine shops, operate in much the same manner. No one bothers to examine the rules that have been handed down to them. The problem is that many rules have been repeated by so many, and for so long, that we’ve come to accept them as fact. Here are a few examples:

“The maximum acceptable burr height for a stamped part is equal to 10 percent of material thickness.”

This may be true if all stampings were produced from plain-carbon steel less than 0.050 in. thick. When burr height begins to approach 0.003 in., they start to become noticeable. In some instances, burr height greater than 0.005 in. can become dangerous, with the potential to cut assembly work-

Peter Ulintz has worked in the metal stamping and tool and die industries since 1978. He has been employed with the Anchor Manufacturing Group in Cleveland, OH, since 1989. His background includes tool and die making, tool engineering, process engi- neering, engineering management and product devel- opment. Peter speaks regularly at PMA seminars and conferences. He is also vice president of the North American Deep Drawing Research Group.

Peter Ulintz pete.ulintz@toolingbydesign.com www.toolingbydesign.com

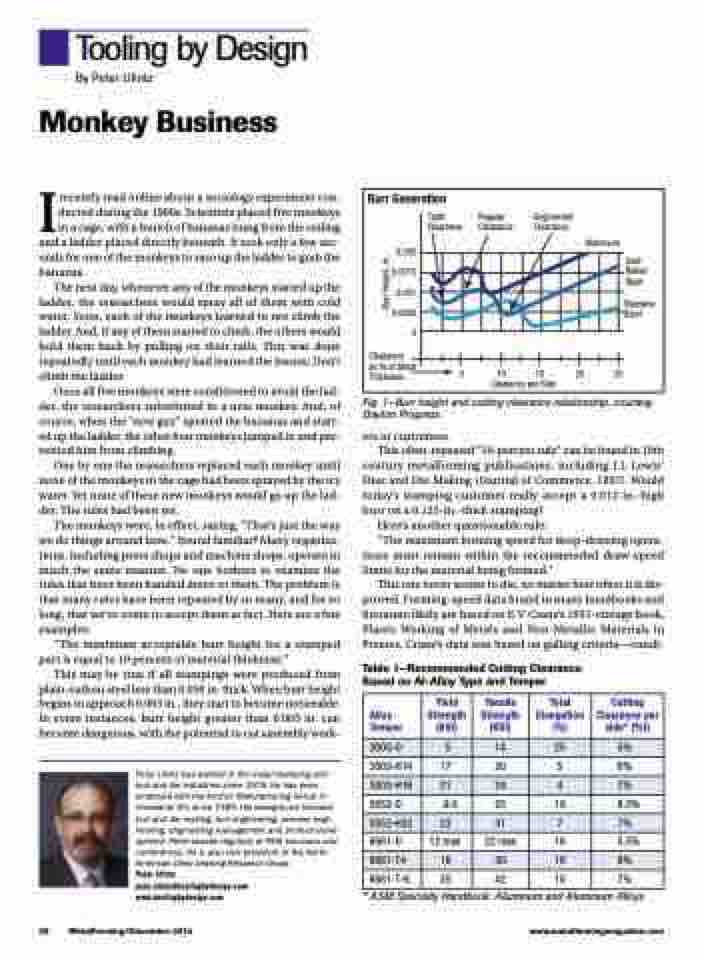

Fig. 1—Burr height and cutting clearance relationship, courtesy Dayton Progress.

ers or customers.

This often-repeated “10-percent rule” can be found in 19th

century metalforming publications, including J.L Lewis’ Dies and Die Making (Journal of Commerce, 1897). Would today’s stamping customer really accept a 0.012-in.-high burr on a 0.125-in.-thick stamping?

Here’s another questionable rule:

“The maximum forming speed for deep-drawing opera- tions must remain within the recommended draw-speed limits for the material being formed.”

This one never seems to die, no matter how often it is dis- proved. Forming-speed data found in many handbooks and literature likely are based on E.V. Crane’s 1931-vintage book, Plastic Working of Metals and Non-Metallic Materials in Presses. Crane’s data was based on galling criteria—condi-

Table 1—Recommended Cutting Clearance Based on Al-Alloy Type and Temper

Burr Generation

Tight Clearance

Regular Clearance

Engineered Clearance

0.002 0.0015 0.001 0.0005 0

Clearance

as % of Stock Thickness

Aluminum

Stainless Steel

Cold Rolled Steel

5 10 15 20 25 Clearance per Side

Alloy - Temper

Yield Strength (KSI)

Tensile Strength (KSI)

Total Elongation (%)

Cutting Clearance per side* (%t)

3003-O

5

14

25

5%

3003-H14

17

20

5

6%

3003-H16

21

24

4

7%

5052-O

9.5

25

19

6.5%

5052-H32

23

31

7

7%

6061-O

12 max

22 max

16

5.5%

6061-T4

16

30

16

6%

6061-T-6

35

42

10

7%

38 MetalForming/December 2014

www.metalformingmagazine.com

* ASM Specialty Handbook: Aluminum and Aluminum Alloys

Burr Height , in.