Page 28 - MetalForming November 2014

P. 28

Press Applications

delivers energy by changing its RPM. Typically, the flywheel is designed to deliver 10 to 20 percent of its stored energy to the ram when engaged with- in the work cycle.

To determine flywheel energy:

E(ft.lb.)=1.7xWk2 x(N )2 100

If the press operates at 30 strokes/min., or 360 RPM at the fly- wheel, a 15-percent slowdown occurs and estimated flywheel inertia is 10,800 lb-ft.2 The energy is:

E=1.7xwk2 x(360)2=237,945ft.lb. 100

E=237,935ft.lb.–(1.7) x(10,800lb.ft.2)

x ((360) x (1 – 0.15))2

100 E = 66,029 ft. lb.

The motor/drive

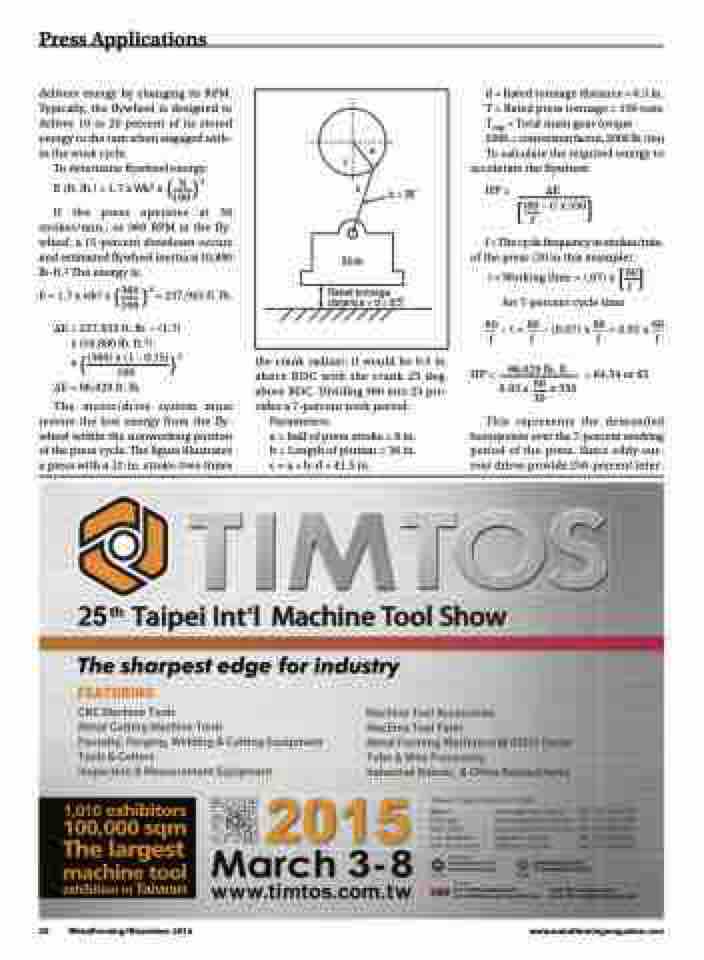

restore the lost energy from the fly- wheel within the nonworking portion of the press cycle. The figure illustrates a press with a 12-in. stroke (two times

a c

x

Slide

b = 36"

d = Rated tonnage distance = 0.5 in. T = Rated press tonnage = 150 tons Tmg = Total main gear torque

2000 = conversion factor, 2000 lb./ton To calculate the required energy to

accelerate the flywheel:

HP= E [(60–t)x550]

f

f = The cycle frequency or strokes/min. of the press (30 in this example).

t = Working time = (.07) x [60] f

26 MetalForming/November 2014

www.metalformingmagazine.com

system

must

Rated tonnage distance = d = 0.5"

the crank radius); it would be 0.5 in. above BDC with the crank 25 deg. above BDC. Dividing 360 into 25 pro- vides a 7-percent work period.

Parameters: a=halfofpressstroke=6in. b = Length of pitman = 36 in. c=a+b-d=41.5in.

for 7-percent cycle time

60 – t = 60 – (0.07) x 60 = 0.93 x 60

HP =

f f f f

66,029 lb. ft.

60 = 64.54 or 65

0.93 x 30 x 550

This represents the demanded horsepower over the 7-percent working period of the press. Since eddy-cur- rent drives provide 250-percent inter-