Page 67 - MetalForming August 2014

P. 67

ε

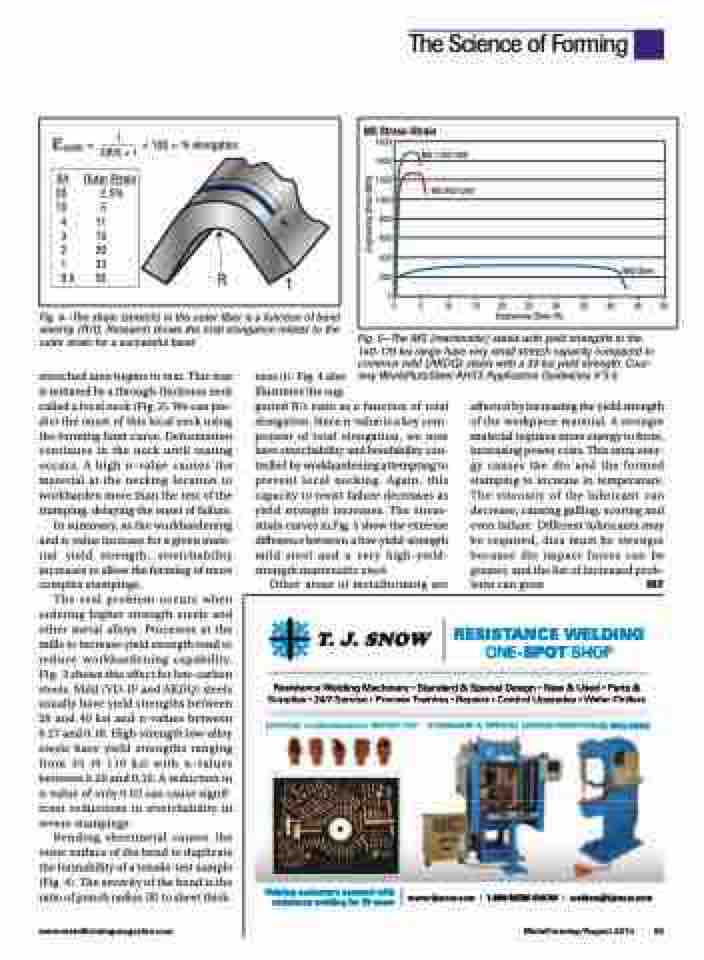

Fig. 4—The strain (stretch) in the outer fiber is a function of bend severity (R/t). Research shows the total elongation relates to the outer strain for a successful bend.

stretched area begins to tear. This tear is initiated by a through-thickness neck called a local neck (Fig. 2). We can pre- dict the onset of this local neck using the forming limit curve. Deformation continues in the neck until tearing occurs. A high n-value causes the material at the necking location to workharden more than the rest of the stamping, delaying the onset of failure.

In summary, as the workhardening and n-value increase for a given mate- rial yield strength, stretchability increases to allow the forming of more complex stampings.

The real problem occurs when ordering higher strength steels and other metal alloys. Processes at the mills to increase yield strength tend to reduce workhardening capability. Fig. 3 shows this effect for low-carbon steels. Mild (VD-IF and AKDQ) steels usually have yield strengths between 20 and 40 ksi and n-values between 0.27 and 0.18. High-strength low-alloy steels have yield strengths ranging from 35 t0 110 ksi with n-values between 0.20 and 0.10. A reduction in n-value of only 0.02 can cause signif- icant reductions in stretchability in severe stampings.

Bending sheetmetal causes the outer surface of the bend to duplicate the formability of a tensile-test sample (Fig. 4). The severity of the bend is the ratio of punch radius (R) to sheet thick-

Fig. 5—The MS (martensitic) steels with yield strengths in the 140-170 ksi range have very small stretch capacity compared to common mild (AKDQ) steels with a 30 ksi yield strength. Cour- tesy WorldAutoSteel AHSS Application Guidelines V 5.0.

The Science of Forming

outer = 1 × 100 = % elongation 2(R/t) + 1

R/t Outer Strain 20 2.5% 10 5

4 11 3 15 2 20 1 33 0.5 50

R

t

MS Stress-Strain

1600 1400 1200 1000

800 600 400 200

0

0 5 10 15 20 25 30 35 40 45 50

Engineering Strain (%)

MS 1150/1400

MS 950/1200

Mild Steel

ness (t). Fig. 4 also

illustrates the sug-

gested R/t ratio as a function of total elongation. Since n-value is a key com- ponent of total elongation, we now have stretchability and bendability con- trolled by workhardening attempting to prevent local necking. Again, this capacity to resist failure decreases as yield strength increases. The stress- strain curves in Fig. 5 show the extreme difference between a low-yield-strength mild steel and a very high-yield- strength martensitic steel.

affected by increasing the yield strength of the workpiece material. A stronger material requires more energy to form, increasing power costs. This extra ener- gy causes the die and the formed stamping to increase in temperature. The viscosity of the lubricant can decrease, causing galling, scoring and even failure. Different lubricants may be required, dies must be stronger because die impact forces can be greater, and the list of increased prob- lems can grow. MF

RESISTANCE WELDING ONE-SPOT-SHOP

Other areas of metalforming are

& Supplies • 24/7 Service • Process Training • Repairs • Control Upgrades • Water Chillers

Resistance Welding M

Ma

ac

ch

hi

in

ne

er

ry

y•

•S

St

ta

an

nd

da

ar

rd

d&

&S

Sp

pe

ec

ci

ia

al

lD

De

es

s

si

ig

gn

n •

• N

Ne

ew

w &

& U

Us

se

ed

d •

• P

Pa

ar

rt

ts

s &

DIVERSE CONSUMABLES INVENTORY

STANDARD & SPECIAL DESIGN RESISTANCE WELDERS

www.metalformingmagazine.com

MetalForming/August 2014 65

Helpingcustomerssucceedwith resistance welding for 50 years

www.tjsnow.com | 1-800-NOW-SNOW | welders@tjsnow.com

Engineering Stress (MPa)