Page 28 - MetalForming November 2012

P. 28

Center Dies Quickly

and Accurately

...with no prying and bumping, using the methods and equipment described here.

BY DAVID ALKIRE SMITH

Locating dies on the bolster cen- terline quickly and accurately is an essential quick-die-change (QDC) task. The alternative to having a good method for centering your dies is time wasted prying and bumping dies into approximate location, often to find that jobs run scrap in spite of labo- rious trial-and-error efforts.

Good QDC centerline locating methods exist, including use of cen- terline keys and locating pins.

Centerline Keys

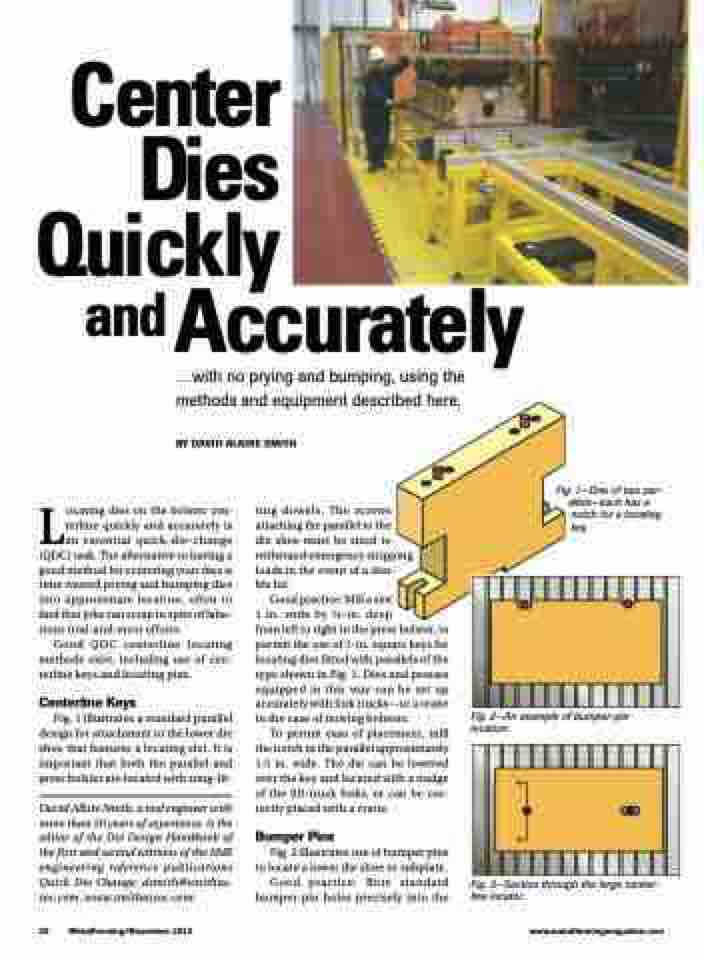

Fig. 1 illustrates a standard parallel design for attachment to the lower die shoe that features a locating slot. It is important that both the parallel and press bolster are located with snug-fit-

David Alkire Smith, a tool engineer with more than 50 years of experience, is the editor of the Die Design Handbook of the first and second editions of the SME engineering reference publications Quick Die Change; dsmith@smithas- soc.com, www.smithassoc.com.

ting dowels. The screws attaching the parallel to the

die shoe must be sized to withstand emergency stripping loads in the event of a dou- ble hit.

Good practice: Mill a slot

1 in. wide by 1⁄2-in. deep

from left to right in the press bolster, to permit the use of 1-in. square keys for locating dies fitted with parallels of the type shown in Fig. 1. Dies and presses equipped in this way can be set up accurately with fork trucks—or a crane in the case of moving bolsters.

To permit ease of placement, mill the notch in the parallel approximately 1.5 in. wide. The die can be lowered over the key and located with a nudge of the lift-truck forks, or can be cor- rectly placed with a crane.

Bumper Pins

Fig. 2 illustrates use of bumper pins to locate a lower die shoe or subplate. Good practice: Bore standard bumper-pin holes precisely into the

Fig. 1—One of two par- allels—each has a

notch for a locating key.

Fig. 2—An example of bumper-pin location.

26 MetalForming/November 2012

www.metalformingmagazine.com

Fig. 3—Section through the large center- line locator.