Page 39 - MetalForming December 2011

P. 39

Tooling Technology

Steady Hands Heal Wounded Dies

Welder Pete Mourouzis is more artist than fabricator, performing, as he calls it, “sculpture in reverse” to deposit laser and micro-tig welds with pinpoint accuracy while repairing

worn and damaged tools. To some, he may appear more doctor than artist.

BY BRAD F. KUVIN, EDITOR

As a former moldmaker, Pete Mourouzis fully under- stands the need for speed and workmanship when it comes to tool, die and mold repair welding. As owner of Wicked Welding, Inc., Dayton, OH, Mourouzis applies his precision-welding skill and knowledge daily to help manufacturers return worn or damaged tools back to service. At his disposal are two welders, in addition to himself; an array of precision micro-tig (gas-tungsten arc) welding systems and traditional tig-welding setups; and two micro-laser-welding systems. Mourouzis and his team perform not only emergency-room repairs on tooling but also enjoy a thriving wellness program that has it included in some of its customers’ routers, performing planned maintenance-welding procedures.

“Half of the work we get in here we turn around in one day, and another 25 percent in two days,” says Mourouzis. “To many of our customers, turn-around time is more crit- ical than price, and that’s where our ability to laser-weld comes up big. While it’s a relatively slow process in terms of deposition rate, if I don’t have to preheat we can turn around work in hours rather than days.”

We walked around Wicked Welding’s 4000-sq.-ft. shop while welders were busy repairing mold tooling, and learned first-hand how the steady-handed team provides

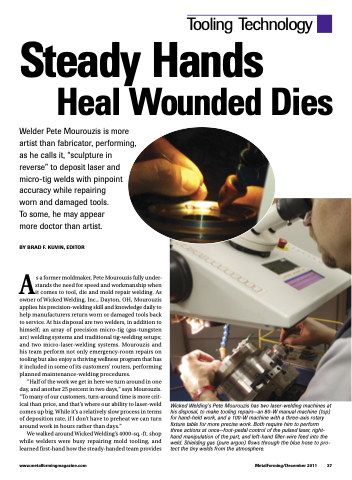

Wicked Welding’s Pete Mourouzis has two laser-welding machines at his disposal, to make tooling repairs—an 80-W manual machine (top) for hand-held work, and a 100-W machine with a three-axis rotary fixture table for more precise work. Both require him to perform three actions at once—foot-pedal control of the pulsed laser, right- hand manipulation of the part, and left-hand filler-wire feed into the weld. Shielding gas (pure argon) flows through the blue hose to pro- tect the tiny welds from the atmosphere.

www.metalformingmagazine.com

MetalForming/December 2011 37