Page 38 - MetalForming December 2011

P. 38

The Science of Forming

Tooling Technology

Punch

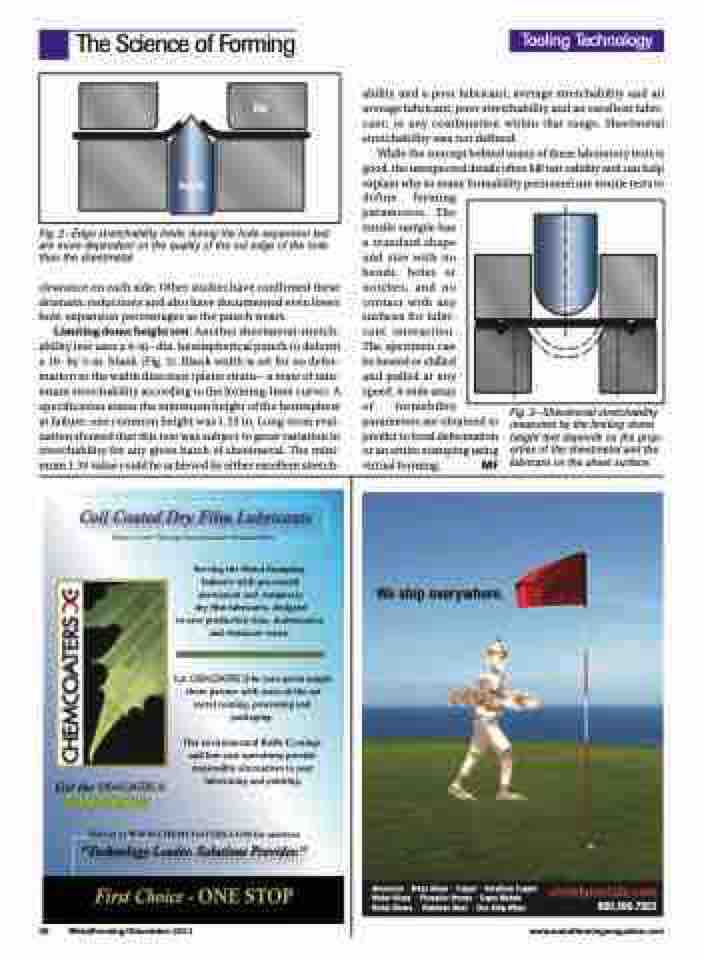

Fig. 2—Edge stretchability limits during the hole-expansion test are more dependent on the quality of the cut edge of the hole than the sheetmetal.

clearance on each side. Other studies have confirmed these dramatic reductions and also have documented even lower hole-expansion percentages as the punch wears.

Limiting dome height test: Another sheetmetal-stretch- ability test uses a 4-in.-dia. hemispherical punch to deform a 10- by 5-in. blank (Fig. 3). Blank width is set for no defor- mation in the width direction (plane strain—a state of min- imum stretchability according to the forming-limit curve). A specification states the minimum height of the hemisphere at failure; one common height was 1.33 in. Long-term eval- uation showed that this test was subject to great variation in stretchability for any given batch of sheetmetal. The mini- mum 1.33 value could be achieved by either excellent stretch-

parameters. The

tensile sample has

a standard shape

and size with no

bends, holes or notches, and no contact with any surfaces for lubri-

cant interaction.

The specimen can

be heated or chilled

and pulled at any

speed. A wide array

of formability parameters are obtained to predict to local deformation or an entire stamping using virtual forming. MF

We ship everywhere.

Fig. 3—Sheetmetal stretchability measured by the limiting dome height test depends on the prop- erties of the sheetmetal and the lubricant on the sheet surface.

36 MetalForming/December 2011

www.metalformingmagazine.com

Die

ability and a poor lubricant; average stretchability and an average lubricant; poor stretchability and an excellent lubri- cant; or any combination within that range. Sheetmetal stretchability was not defined.

While the concept behind many of these laboratory tests is good, the unexpected details often kill test validity and can help explain why so many formability personnel use tensile tests to define forming

• Aluminum • Brass Alloys • Copper • Beryllium Copper christymetals.com

• Nickel Alloys • Phosphor Bronze • Cupro Nickels • Nickel Silvers • Stainless Steel • Zinc Strip Alloys

800.356.7923