Page 28 - MetalForming April 2009

P. 28

Automated Turret Press

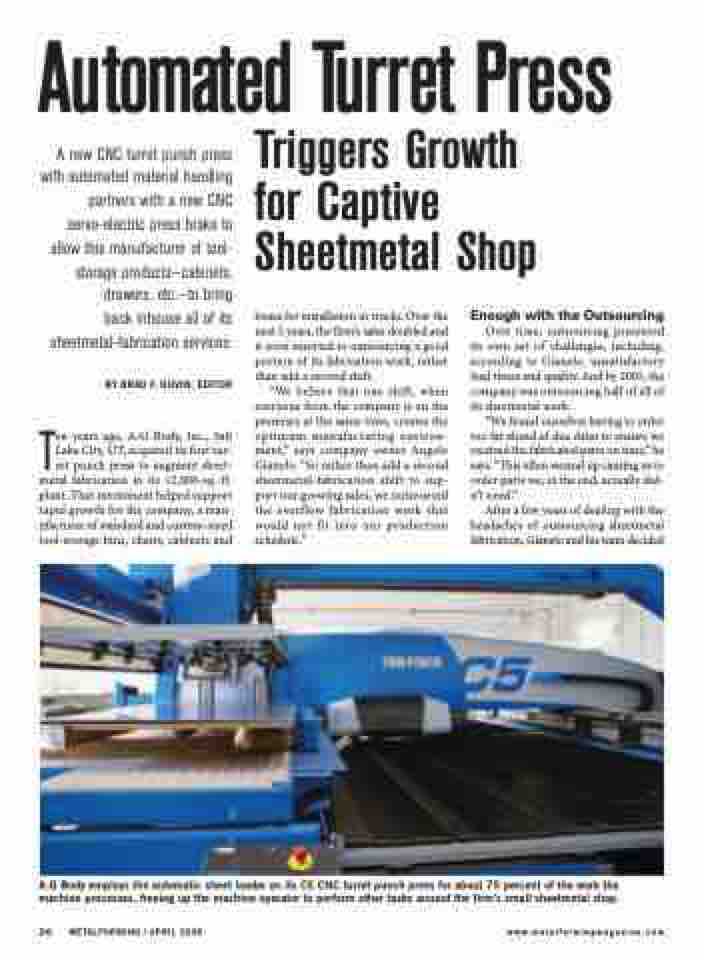

A new CNC turret punch press with automated material handling partners with a new CNC servo-electric press brake to allow this manufacturer of tool- storage products—cabinets, drawers, etc.—to bring back inhouse all of its sheetmetal-fabrication services.

BY BRAD F. KUVIN, EDITOR

Ten years ago, A-G Body, Inc., Salt Lake City, UT, acquired its first tur- ret punch press to augment sheet- metal fabrication in its 12,000-sq.-ft. plant. That investment helped support rapid growth for the company, a man- ufacturer of standard and custom-sized tool-storage bins, chests, cabinets and

Triggers Growth for Captive Sheetmetal Shop

boxes for installation in trucks. Over the next 5 years, the firm’s sales doubled and it soon resorted to outsourcing a good portion of its fabrication work, rather than add a second shift.

“We believe that one shift, when everyone from the company is on the premises at the same time, creates the optimum manufacturing environ- ment,” says company owner Angelo Gianelo. “So rather than add a second sheetmetal-fabrication shift to sup- port our growing sales, we outsourced the overflow fabrication work that would not fit into our production schedule.”

Enough with the Outsourcing

Over time, outsourcing presented its own set of challenges, including, according to Gianelo, unsatisfactory lead times and quality. And by 2005, the company was outsourcing half of all of its sheetmetal work.

“We found ourselves having to order too far ahead of due dates to ensure we received the fabricated parts on time,” he says. “This often wound up causing us to order parts we, in the end, actually did- n’t need.”

After a few years of dealing with the headaches of outsourcing sheetmetal fabrication, Gianelo and his team decided

A-G Body employs the automatic sheet loader on its C5 CNC turret punch press for about 75 percent of the work the machine processes, freeing up the machine operator to perform other tasks around the firm’s small sheetmetal shop.

26 METALFORMING / APRIL 2009 www.metalformingmagazine.com