Page 93 - MetalForming October 2017

P. 93

The Science of Forming

50 40 30 20 10

0

Location A

6.8

Location B 6.8

6.0 5.0

Grid Pattern Centers

6.0 3.8

2.5 Depth

Grid Pattern Centers

5.0

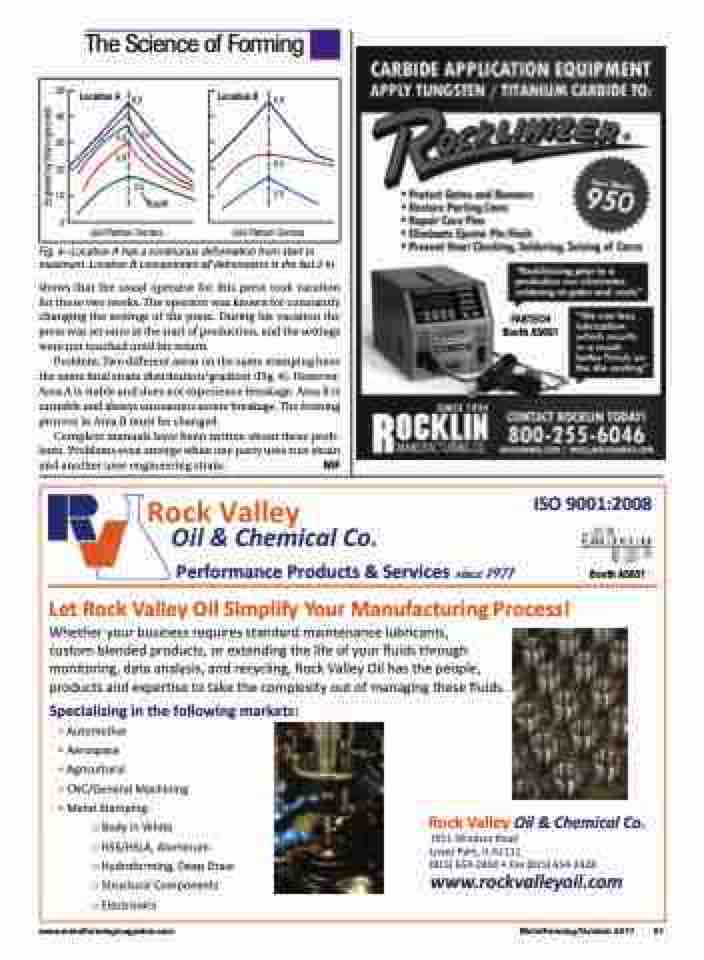

Fig. 4—Location A has a continuous deformation from start to maximum. Location B concentrates all deformation in the last 2 in.

shows that the usual operator for this press took vacation for those two weeks. The operator was known for constantly changing the settings of the press. During his vacation the press was set once at the start of production, and the settings were not touched until his return.

Problem: Two different areas on the same stamping have the same final strain distribution/gradient (Fig. 4). However, Area A is stable and does not experience breakage. Area B is unstable and always encounters severe breakage. The forming process in Area B must be changed.

Complete manuals have been written about these prob- lems. Problems even emerge when one party uses true strain and another uses engineering strain. MF

FABTECH Booth A5651

ISO 9001:2008

Performance Products & Services ����� ����

Let Rock Valley Oil Simplify Your Manufacturing Process!

Whether your business requires standard maintenance lubricant��

custom blended product�, �� ��������� ��� ���� �� ���� ������ ������� ����������� ���� ��������� ��� ���������� ���� ������ ��� ha� ��� ������� �������� ��� ��������� �� ���� ��� ���������� ��� �� �������� ����� �������

Specializing in the following markets:

• ����������

• Aerospace

• ������������

• ����������� ��������� • ����� ���������

� ���� �� �����

� ��������� ��������

� ������������� ���� ���� � ���������� ����������

� �����������

Booth A5651

Rock Valley Oil & Chemical Co. 1911 Windsor Road

����� ����� �� �����

����� �������� � ��� ����� ��������

www.rockvalleyoil.com

www.metalformingmagazine.com

MetalForming/October 2017 91

Engineering Strain (percent)