Page 39 - MetalForming June 2017

P. 39

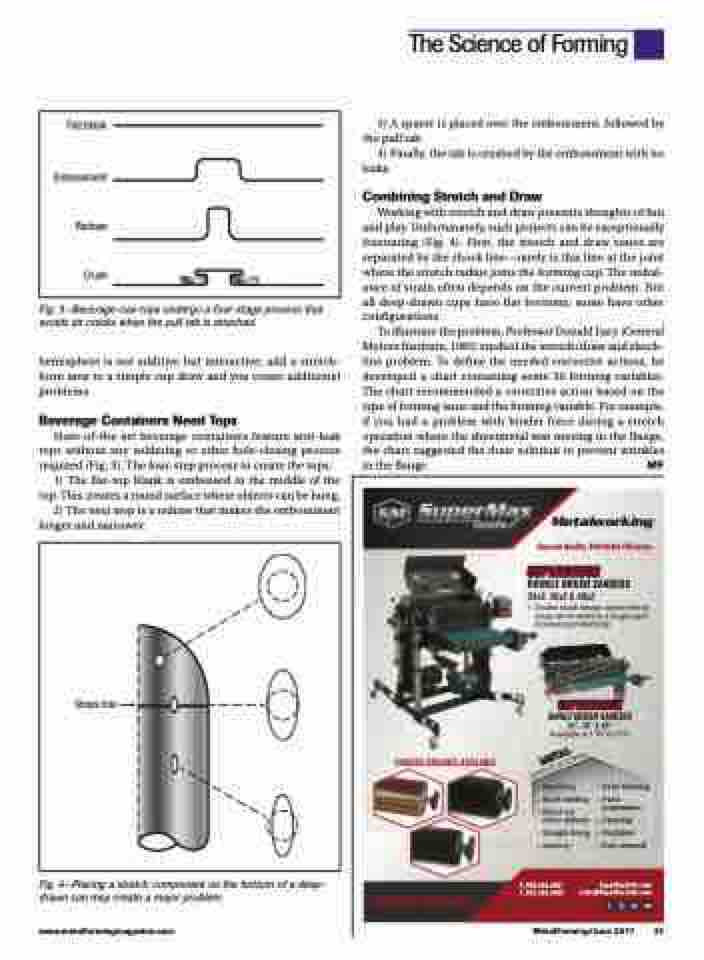

Fig. 3—Beverage-can tops undergo a four-stage process that avoids air cracks when the pull tab is attached.

hemisphere is not additive but interactive; add a stretch- form area to a simple cup draw and you create additional problems.

Beverage Containers Need Tops

State-of-the-art beverage containers feature anti-leak tops without any soldering or other hole-closing process required (Fig. 3). The four-step process to create the tops:

1) The flat-top blank is embossed in the middle of the top. This creates a round surface where objects can be hung. 2) The next step is a redraw that makes the embossment

longer and narrower.

3) A spacer is placed over the embossment, followed by the pull tab.

4) Finally, the tab is crushed by the embossment with no leaks.

Combining Stretch and Draw

Working with stretch and draw presents thoughts of fun and play. Unfortunately, such projects can be exceptionally frustrating (Fig. 4). First, the stretch and draw zones are separated by the shock line—rarely is this line at the joint where the stretch radius joins the forming cup. The unbal- ance of strain often depends on the current problem. Not all deep-drawn cups have flat bottoms; some have other configurations.

To illustrate the problem, Professor Donald Eary (General Motors Institute, 1985) studied the stretch/draw and shock- line problem. To define the needed corrective actions, he developed a chart containing some 30 forming variables. The chart recommended a corrective action based on the type of forming issue and the forming variable. For example, if you had a problem with binder force during a stretch operation where the sheetmetal was moving in the flange, the chart suggested the draw solution to prevent wrinkles

The Science of Forming

Flat blank

Embossment

Redraw

Crush

in the flange.

VARIOUS BRUSHES AVAILABLE

SANDING SIMPLIFIED.

MF

Metalworking

Superior Quality. Affordable Efficiency.

Shock line

SUPERBRUSH

DOUBLE BRUSH SANDERS

24x2, 36x2 & 49x2

Double brush design saves time by using two brushes in a single pass increasing productivity.

SUPERBRUSH

SINGLE BRUSH SANDERS

24”, 36” & 49”

Available in 1 Ph or 3 Ph

Deburring Scuff sanding

Blend out minor defects

����� ��������

Paint preparation

Cleaning Straight-lining Oxidation

Fig. 4—Placing a stretch component on the bottom of a deep- drawn can may create a major problem.

Graining

P. 888.454.3401 F. 651.454.3465

Rust removal

SuperMaxTools.com sales@SuperMaxTools.com

www.metalformingmagazine.com

MetalForming/June 2017 37

METAL APPLICATIONS