Page 24 - MetalForming May 2017

P. 24

Straightening for Fineblanking

This fineblanking pioneer seeks and finds the ideal coil-feed line to suit its latest press, capable of meeting the dimensional-tolerance requirements for producing near-net- shape automotive-brake backing plates.

BY BRAD F. KUVIN, EDITORIAL DIRECTOR

For nearly 60 years, automotive brake-component manufacturer Util Group, headquartered in Italy, has been supplying many of the world’s OEMs of cars, trucks and other vehicles with fineblanked and stamped backing plates, brake shoes, piston clips, springs and other parts. Most recently, it launched production of components for the 2017 Volvo S90, Jeep Cherokee, Hyundai Veloster and Tucson, and Mazda CX-5.

As explained by Frank Taraschi, pres- ident and general manager—Americas, the firm operates four facilities employ- ing 1400 people around the world, and is an early adopter of fineblanking tech- nology—a process widely used for

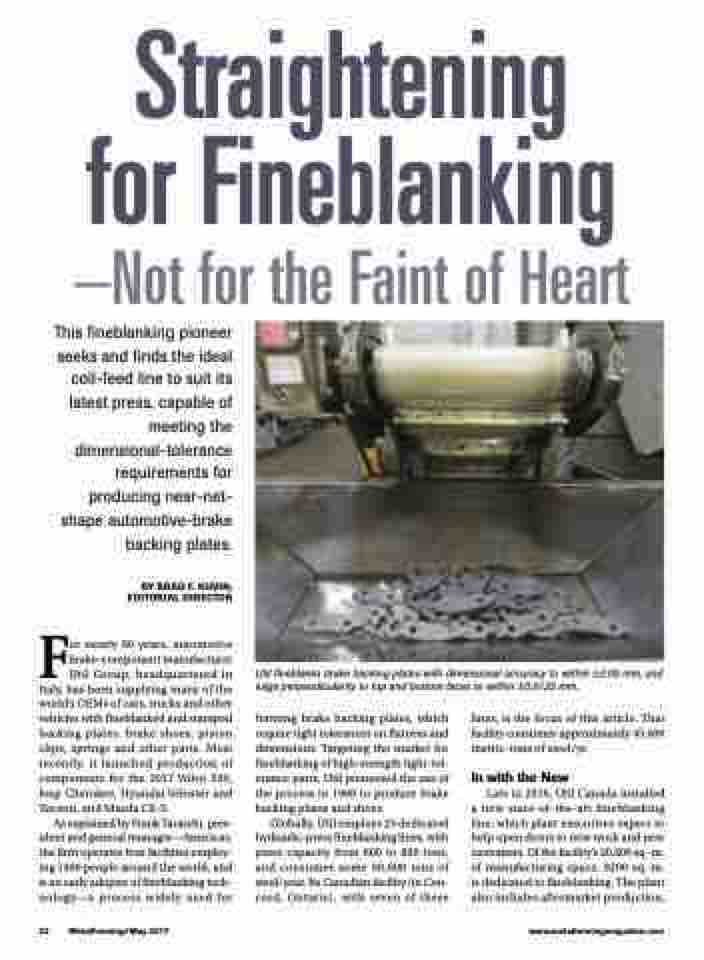

Util fineblanks brake backing plates with dimensional accuracy to within ±0.05 mm, and edge perpendicularity to top and bottom faces to within ±0.0125 mm..

22 MetalForming/May 2017

www.metalformingmagazine.com

forming brake backing plates, which require tight tolerances on flatness and dimensions. Targeting the market for fineblanking of high-strength tight-tol- erance parts, Util pioneered the use of the process in 1968 to produce brake backing plates and shoes.

Globally, Util employs 25 dedicated hydraulic-press fineblanking lines, with press capacity from 600 to 880 tons, and consumes some 90,000 tons of steel/year. Its Canadian facility (in Con- cord, Ontario), with seven of these

lines, is the focus of this article. That facility consumes approximately 45,000 metric-tons of steel/yr.

In with the New

Late in 2016, Util Canada installed a new state-of-the-art fineblanking line, which plant executives expect to help open doors to new work and new customers. Of the facility’s 20,000 sq.-m. of manufacturing space, 9200 sq.-m. is dedicated to fineblanking. The plant also includes aftermarket production,