Page 18 - MetalForming May 2017

P. 18

Better Tooling for

Super

Strong Steels

Advanced grades of steel, includ- ing advanced high-strength steel (AHSS) and ultra-high- strength steel (UHSS) with tensile strengths of greater than 1000 MPa (1 GPa) have been adopted rapidly in the automotive industry to meet stringent fuel economy targets, enhance occu- pant protection and improve vehicle performance. AHSS provides optimal performance due to its excellent strength and ductility.

However, from the perspective of stamping-die performance, these AHSS prove challenging when paired with tra- ditional die materials and surface-treat- ment technologies. This can lead to sig- nificant cost increases resulting from frequent die maintenance and inter- ruptions in the manufacturing process.

To assist metalformers, the Auto/ Steel Partnership’s (A/SP) Stamping Tooling Optimization (STO) team has been studying the effects of AHSS and UHSS on tooling design and mainte- nance. The results of their work have been implemented in each of the mem- ber auto companies’ (FCA USA LLC, General Motors and Ford) die-design

Dave Anderson is senior director–auto- motive market and long products pro- gram for Steel Market Development Institute, Washington, D.C.; tel. 202/452- 7100, www.smdisteel.org.

BY DAVE ANDERSON

standards upon completion of different phases of the project.

The international steel industry has completed several collaborative proj- ects beginning with the UltraLight Steel Auto Body (ULSAB) project in 1998 and continuing through the WorldAu- toSteel FutureSteelVehicle (FSV ) proj- ect in 2011. Each of these projects achieved significant weight savings

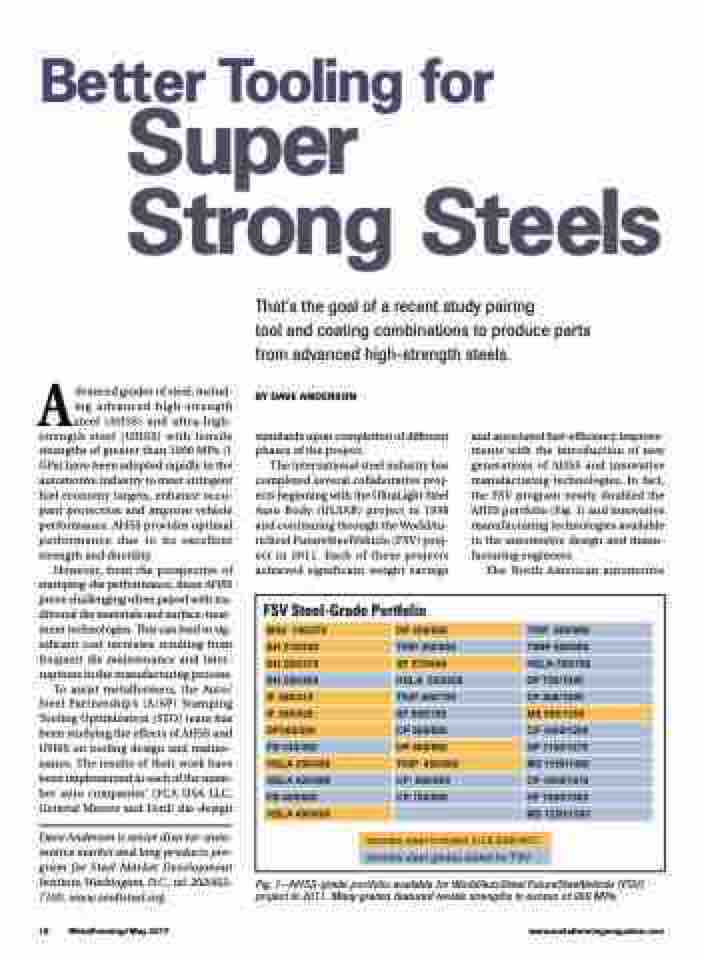

FSV Steel-Grade Portfolio

and associated fuel-efficiency improve- ments with the introduction of new generations of AHSS and innovative manufacturing technologies. In fact, the FSV program nearly doubled the AHSS portfolio (Fig. 1) and innovative manufacturing technologies available to the automotive design and manu- facturing engineers.

The North American automotive

16 MetalForming/May 2017

www.metalformingmagazine.com

That’s the goal of a recent study pairing

tool and coating combinations to produce parts from advanced high-strength steels.

Fig. 1—AHSS-grade portfolio available for WorldAutoSteel FutureSteelVehicle (FSV) project in 2011. Many grades featured tensile strengths in excess of 900 MPa.