Page 35 - MetalForming March 2017

P. 35

radii or groups of radii should be at least 0.188 in. wide. Any number of radii may be fitted onto the tool—lim- iting factors are tool size and strength.

Small-Diameter Holes: Stay Sharp

When punching relatively small- diameter or narrow holes, be sure that tools are properly sharpened and main- tained. In general, for nonguided tool- ing it is recommended that punch to material ratio be 0.75:1 for aluminum, 1:1 for mild steel and 2:1 for stainless steel. For example, if the material to be punched is 0.078-in.-thick alu- minum, it is reasonable to punch a 0.059-in.-dia. hole. When using fully guided tooling, recommended punch- to-material ratios are 0.5:1 for alu- minum, 0.75:1 for mild steel and 1:1 for stainless steel.

When producing large-diameter holes, although tooling is available for the largest tool station, such holes may exceed press capacities, especially when punching high-shear-strength materials. Here, creating the hole with more than one hit may solve the prob- lem. Using smaller holes to break long perimeters on large tools can cut needed tonnage by half or more, with- out resorting to nibbling the entire periphery.

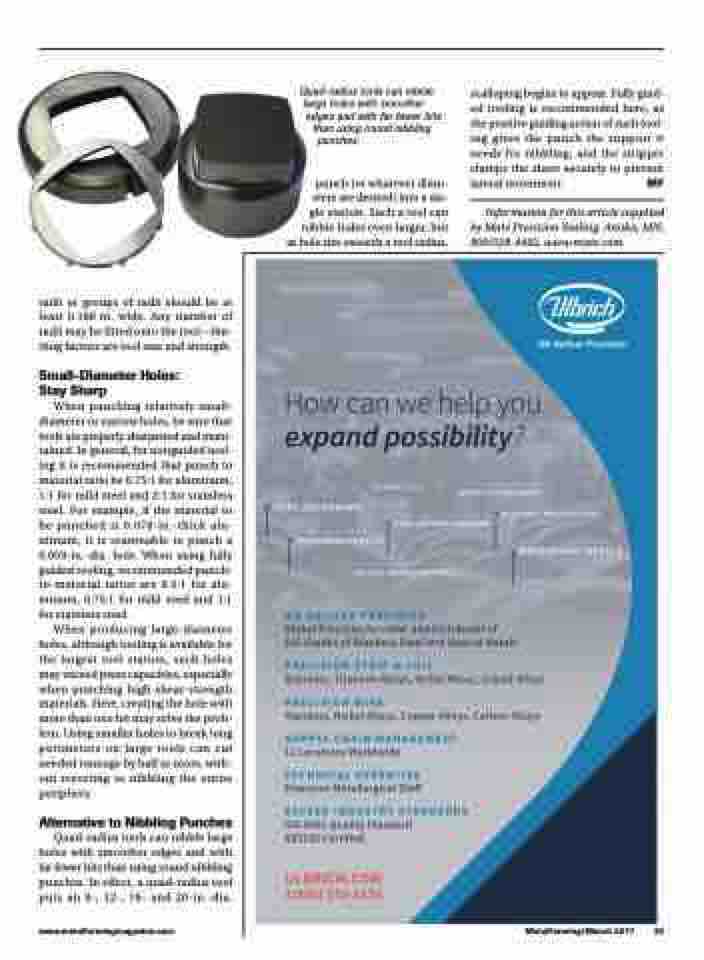

Alternative to Nibbling Punches

Quad-radius tools can nibble large holes with smoother edges and with far fewer hits than using round nibbling punches. In effect, a quad-radius tool puts an 8-, 12-, 16- and 20-in.-dia.

www.metalformingmagazine.com

MetalForming/March 2017 33

Quad-radius tools can nibble large holes with smoother

edges and with far fewer hits than using round nibbling

punches.

punch (or whatever diam- eters are desired) into a sin- gle station. Such a tool can nibble holes even larger, but as hole size exceeds a tool radius,

scalloping begins to appear. Fully guid- ed tooling is recommended here, as the positive guiding action of such tool- ing gives the punch the support it needs for nibbling, and the stripper clamps the sheet securely to prevent lateral movement. MF

Information for this article supplied by Mate Precision Tooling, Anoka, MN; 800/328-4492, www.mate.com.