Page 39 - MetalForming February 2017

P. 39

thick cold-rolled steel that cannot tol- erate any heat deformation; waterjet is the process of choice.”

Of course, once he finds a new sup- plier that meets/exceeds expectations in terms of quality and delivery, Gold- man considers that supplier ‘preferred’ and has no qualms about sending repeat orders back to that supplier, “provided they hold pricing or get close to it,” he says. “And we’ve had several re-orders; all new orders, though, get put out for quote.”

Noting that the 41 projects quoted on MFG.com accrued a total savings of $70,000, Goldman cites one partic- ularly lucrative job as an example of the benefits realized from online sourc- ing: a machined stainless-steel part that had previously been purchased from an OEM as a cast part, for $125 apiece.

“We purchased 80 of these parts for $17.80 apiece through a supplier found on MFG.com,” he says. “That’s an $8500 savings just on this one order.”

Building a Reputation

MFG.com has some 500 or so shops subscribing under the ‘fabrication’ heading. And, during 2016 it had about 1500 RFQs issued for fabricators; of those, metal fabrication comprised about 80 percent.

For Goldman, finding machine shops and fabricators to bid on quotes requires only that he upload a part- print PDF to the MFG.com site. He typ- ically leaves quotes open for a week or so, and receives eight to 12 quotes per RFQ.

“I can customize the quote require- ments,” he notes, “and I typically limit mine to North American suppliers. Then, when making my selection, in addition to pricing I also consider the supplier reviews available on the plat- form.”

These reviews, while assisting buy- ers in selecting a supplier, also help to build supplier reputation and gain new customers. So says MFG.com chief marketing officer Chris Mitchell.

“At the same time,” Mitchell says, “suppliers rate the purchasers on per-

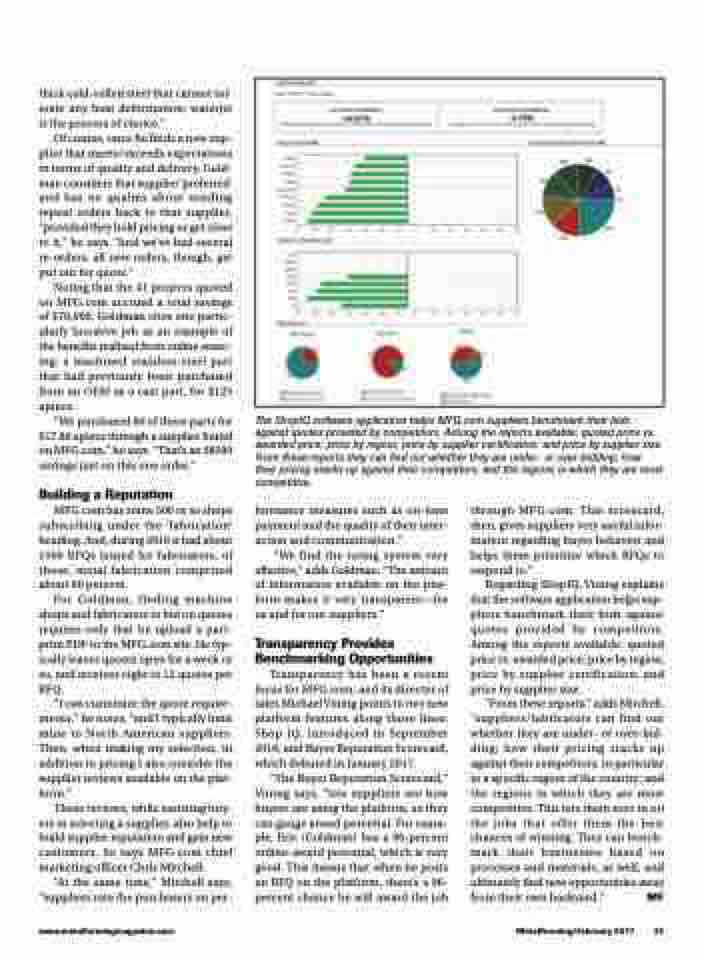

The ShopIQ software application helps MFG.com suppliers benchmark their bids against quotes provided by competitors. Among the reports available: quoted price vs. awarded price; price by region; price by supplier certification; and price by supplier size. From these reports they can find out whether they are under- or over-bidding; how their pricing stacks up against their competitors; and the regions in which they are most competitive.

www.metalformingmagazine.com

MetalForming/February 2017 37

formance measures such as on-time payment and the quality of their inter- action and communication.”

“We find the rating system very effective,” adds Goldman. “The amount of information available on the plat- form makes it very transparent—for us and for our suppliers.”

Transparency Provides Benchmarking Opportunities

Transparency has been a recent focus for MFG.com, and its director of sales Michael Vining points to two new platform features along those lines: Shop IQ, introduced in September 2016; and Buyer Reputation Scorecard, which debuted in January 2017.

“The Buyer Reputation Scorecard,” Vining says, “lets suppliers see how buyers are using the platform, so they can gauge award potential. For exam- ple, Eric (Goldman) has a 96-percent online-award potential, which is very good. This means that when he posts an RFQ on the platform, there’s a 96- percent chance he will award the job

through MFG.com. This scorecard, then, gives suppliers very useful infor- mation regarding buyer behavior and helps them prioritize which RFQs to respond to.”

Regarding ShopIQ, Vining explains that the software application helps sup- pliers benchmark their bids against quotes provided by competitors. Among the reports available: quoted price vs. awarded price; price by region; price by supplier certification; and price by supplier size.

“From these reports,” adds Mitchell, “suppliers/fabricators can find out whether they are under- or over-bid- ding; how their pricing stacks up against their competitors, in particular in a specific region of the country; and the regions in which they are most competitive. This lets them zero in on the jobs that offer them the best chances of winning. They can bench- mark their businesses based on processes and materials, as well, and ultimately find new opportunities away from their own backyard.” MF