Page 37 - MetalForming February 2017

P. 37

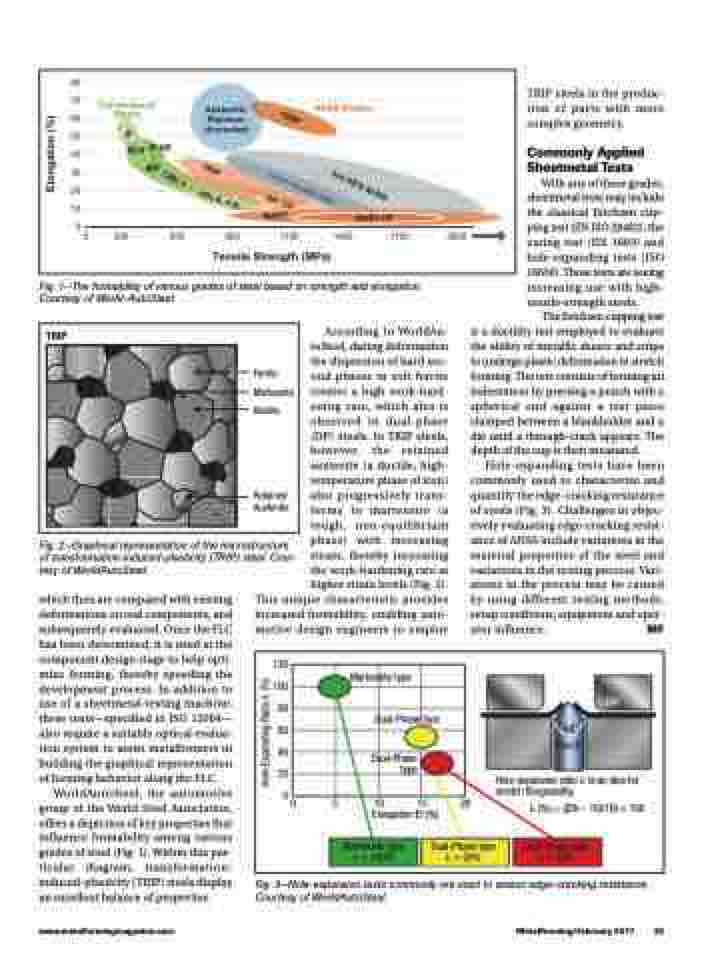

Fig. 1—The formability of various grades of steel based on strength and elongation. Courtesy of World-AutoSteel.

TRIP steels in the produc- tion of parts with more complex geometry.

Commonly Applied Sheetmetal Tests

With any of these grades, sheetmetal tests may include the classical Erichsen cup- ping test (EN ISO 20482), the earing test (EN 1669) and hole-expanding tests (ISO 16630). These tests are seeing increasing use with high- tensile-strength steels.

The Erichsen cupping test is a ductility test employed to evaluate the ability of metallic sheets and strips to undergo plastic deformation in stretch forming. The test consists of forming an indentation by pressing a punch with a spherical end against a test piece clamped between a blankholder and a die until a through-crack appears. The

depth of the cup is then measured. Hole-expanding tests have been commonly used to characterize and quantify the edge-cracking resistance of steels (Fig. 3). Challenges in objec- tively evaluating edge-cracking resist- ance of AHSS include variations in the material properties of the steel and variations in the testing process. Vari- ations in the process may be caused by using different testing methods, setup conditions, equipment and oper-

TRIP

According to WorldAu- toSteel, during deformation the dispersion of hard sec- ond phases in soft ferrite creates a high work-hard- ening rate, which also is observed in dual-phase (DP) steels. In TRIP steels, however, the retained austenite (a ductile, high- temperature phase of iron) also progressively trans- forms to martensite (a tough, non-equilibrium phase) with increasing strain, thereby increasing the work-hardening rate at higher strain levels (Fig. 2).

Fig. 2—Graphical representation of the microstructure of transformation-induced-plasticity (TRIP) steel. Cour- tesy of WorldAutoSteel.

which then are compared with existing deformations on real components, and subsequently evaluated. Once the FLC has been determined, it is used at the component design stage to help opti- mize forming, thereby speeding the development process. In addition to use of a sheetmetal-testing machine, these tests—specified in ISO 12004— also require a suitable optical evalua- tion system to assist metalformers in building the graphical representation of forming behavior along the FLC.

WorldAutoSteel, the automotive group of the World Steel Association, offers a depiction of key properties that influence formability among various grades of steel (Fig. 1). Within this par- ticular diagram, transformation- induced-plasticity (TRIP) steels display an excellent balance of properties.

This unique characteristic provides increased formability, enabling auto- motive design engineers to employ

ator influence.

Hole-expansion ratio λ is an idex for stretch flangeability.

MF

www.metalformingmagazine.com

MetalForming/February 2017 35

Ferrite Martensite Bainite

Retained Austenite

120

100

80

60

40

20

0

Martensite type

Dual-Phase type

Dual-Phase type

Die

Hole-Expanding Ratio λ (%)

0 5 10 15 20 λ(%)=((Dh–10)/10)×100 Elongation El (%)

Martensite type Dual-Phase type Dual-Phase type λ=100% λ=50% λ=25%

Fig. 3—Hole-expansion tests commonly are used to assess edge-cracking resistance. Courtesy of WorldAutoSteel.

60˚

Punch