Page 36 - MetalForming February 2017

P. 36

Testing Ensures Quality of AHSS

Advanced high-strength steels have proven their mettle in automotive and other applications. A key to success in forming these tough materials lies in proper testing.

BY DR. EDUARD SCHENUIT

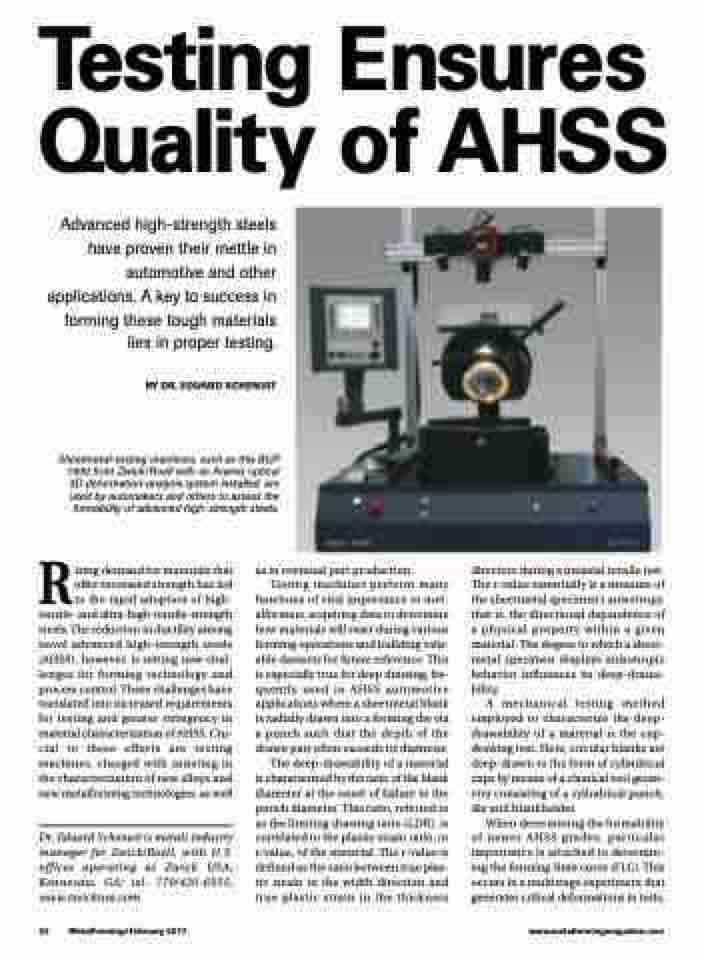

Sheetmetal-testing machines, such as this BUP 1000 from Zwick/Roell with an Aramis optical 3D deformation-analysis system installed, are used by automakers and others to assess the formability of advanced high-strength steels.

Rising demand for materials that offer increased strength has led to the rapid adoption of high- tensile- and ultra-high-tensile-strength steels. The reduction in ductility among novel advanced high-strength steels (AHSS), however, is setting new chal- lenges for forming technology and process control. These challenges have translated into increased requirements for testing and greater stringency in material characterization of AHSS. Cru- cial to these efforts are testing machines, charged with assisting in the characterization of new alloys and new metalforming technologies, as well

Dr. Eduard Schenuit is metals industry manager for Zwick/Roell, with U.S. offices operating as Zwick USA, Kennesaw, GA; tel. 770/420-6555, www.zwickusa.com.

as in eventual part production. Testing machines perform many functions of vital importance to met- alformers, acquiring data to determine how materials will react during various forming operations and building valu- able datasets for future reference. This is especially true for deep drawing, fre- quently used in AHSS automotive applications where a sheetmetal blank is radially drawn into a forming die via a punch such that the depth of the drawn part often exceeds its diameter. The deep-drawability of a material is characterized by the ratio of the blank diameter at the onset of failure to the punch diameter. This ratio, referred to as the limiting drawing ratio (LDR), is correlated to the plastic strain ratio, or r-value, of the material. The r-value is defined as the ratio between true plas- tic strain in the width direction and true plastic strain in the thickness

direction during a uniaxial tensile test. The r-value essentially is a measure of the sheetmetal specimen’s anisotropy, that is, the directional dependence of a physical property within a given material. The degree to which a sheet- metal specimen displays anisotropic behavior influences its deep-drawa- bility.

A mechanical testing method employed to characterize the deep- drawability of a material is the cup- drawing test. Here, circular blanks are deep-drawn to the form of cylindrical cups by means of a classical tool geom- etry consisting of a cylindrical punch, die and blankholder.

When determining the formability of newer AHSS grades, particular importance is attached to determin- ing the forming-limit curve (FLC). This occurs in a multistage experiment that generates critical deformations in tests,

34 MetalForming/February 2017

www.metalformingmagazine.com