Page 24 - MetalForming February 2017

P. 24

Die Springs—

Coil vs. Gas; Best Practices

While the gas-spring industry has done a bang-up job earn- ing market share from coil- spring suppliers, experts interviewed for this article agree that you can’t paint a broad picture when it comes to select- ing the right solution for metalforming dies. Where can stampers still use coil springs? We asked Ray Osborne, vice president of sales at Moeller Precision Tool, Wixom, MI.

“Applications where you don’t need nitrogen,” Osborne says, “may include simpler dies where you don’t have a lot of stripper-pad travel; flat parts that don’t have a lot of form in them; high- speed dies; and tools requiring short strokes such as those used to stamp

electronic parts.”

On the flip side, Jim Glynn, president

gas-spring supplier Special Springs, LLC, Canton, MI, warns against paint- ing the die-spring picture with a broad brush, noting that the majority of dies now are designed with gas springs.

“Coil springs exhibit some limita- tions, due to the greater force required to form or strip,” Glynn says. “This becomes increasingly important as more metalformers begin to fabricate higher-strength materials. You don’t always have room in the die to use as many coil springs as might be needed. Gas springs become the default solu- tion for these jobs. For shorter runs and in areas where you don’t need as

Understand where and when to opt for coil springs rather than nitrogen-gas springs, then follow the best-practice guidelines here to ensure long, safe and effective spring use.

BY BRAD F. KUVIN, EDITORIAL DIRECTOR

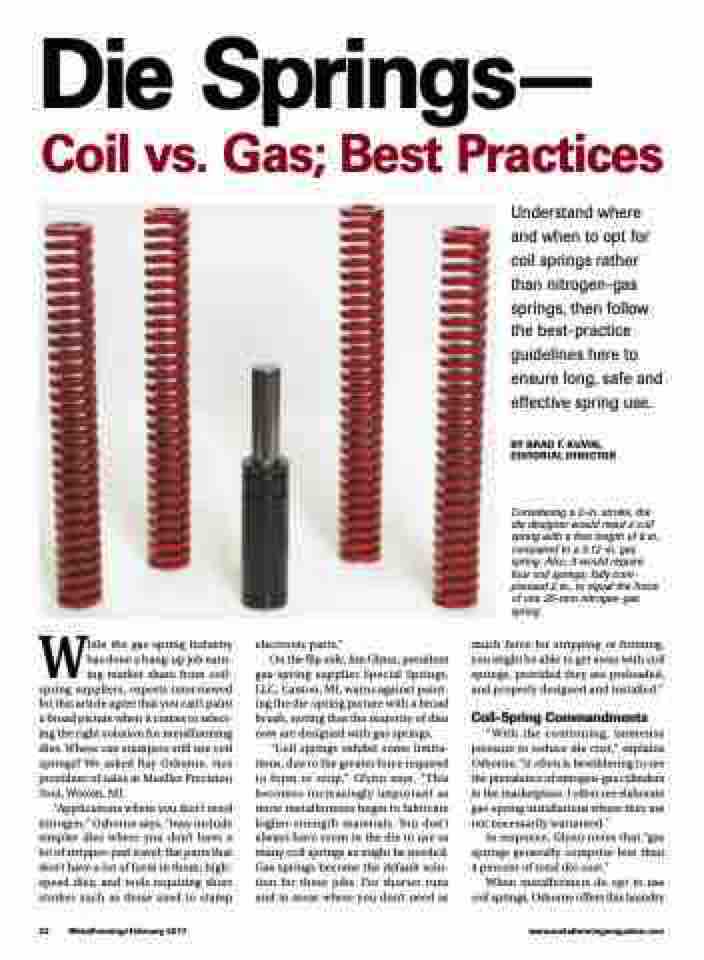

Considering a 2-in. stroke, the die designer would need a coil spring with a free length of 8 in., compared to a 5.12-in. gas spring. Also, it would require four coil springs, fully com- pressed 2 in., to equal the force of one 25-mm nitrogen-gas spring.

much force for stripping or forming, you might be able to get away with coil springs, provided they are preloaded, and properly designed and installed.”

Coil-Spring Commandments

“With the continuing, immense pressure to reduce die cost,” explains Osborne, “it often is bewildering to see the prevalence of nitrogen-gas cylinders in the marketplace. I often see elaborate gas-spring installations where they are not necessarily warranted.”

In response, Glynn notes that “gas springs generally comprise less than 4 percent of total die cost.”

When metalformers do opt to use coil springs, Osborne offers this laundry

22 MetalForming/February 2017

www.metalformingmagazine.com