Page 44 - MetalForming April 2016

P. 44

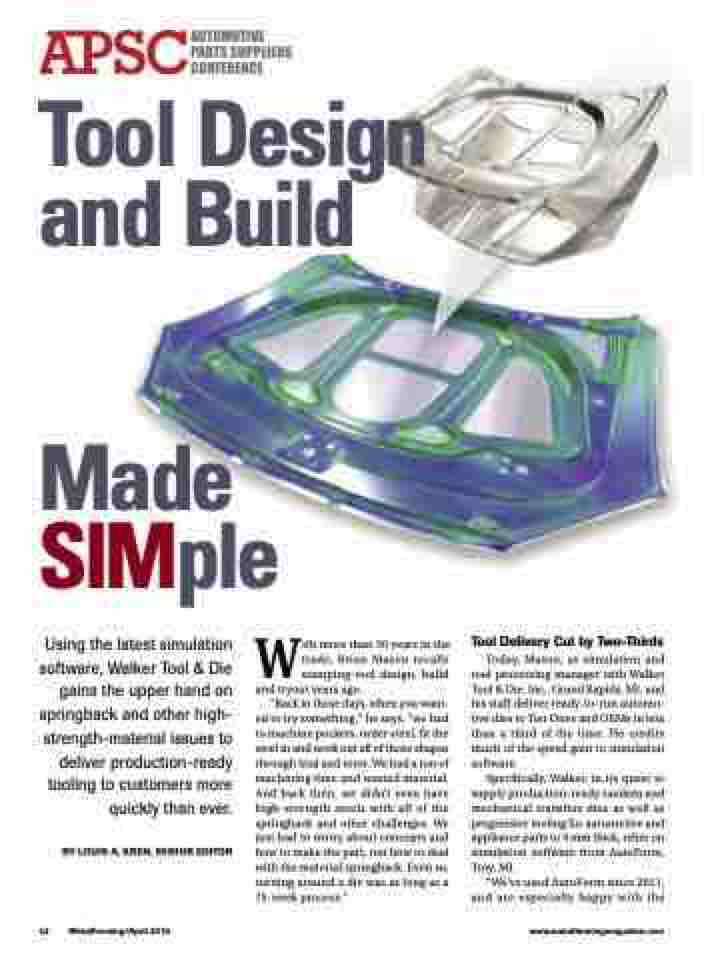

Tool Design and Build

Made SIMple

Using the latest simulation software, Walker Tool & Die gains the upper hand on springback and other high- strength-material issues to deliver production-ready tooling to customers more quickly than ever.

BY LOUIS A. KREN, SENIOR EDITOR

With more than 30 years in the trade, Brian Mason recalls stamping-tool design, build and tryout years ago.

“Back in those days, when you want- ed to try something,” he says, “we had to machine pockets, order steel, fit the steel in and work out all of those shapes through trial and error. We had a ton of machining time and wasted material. And back then, we didn’t even have high-strength steels with all of the springback and other challenges. We just had to worry about concepts and how to make the part, not how to deal with the material springback. Even so, turning around a die was as long as a 75-week process.”

Tool Delivery Cut by Two-Thirds

Today, Mason, as simulation and tool processing manager with Walker Tool & Die, Inc., Grand Rapids, MI, and his staff deliver ready-to-run automo- tive dies to Tier Ones and OEMs in less than a third of the time. He credits much of the speed gain to simulation software.

Specifically, Walker, in its quest to supply production-ready tandem and mechanical transfers dies as well as progressive tooling for automotive and appliance parts to 9 mm thick, relies on simulation software from AutoForm, Troy, MI.

“We’ve used AutoForm since 2011, and are especially happy with the

42

MetalForming/April 2016

www.metalformingmagazine.com