Page 46 - MetalForming April 2016

P. 46

Tool Design and Build Made SIMple

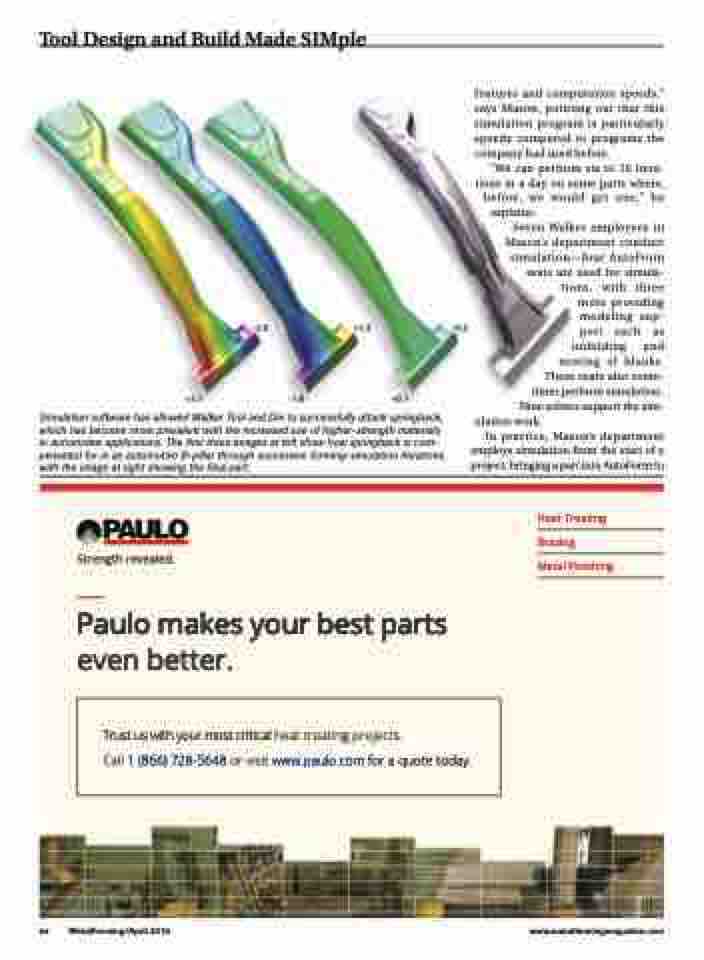

Simulation software has allowed Walker Tool and Die to successfully attack springback,

which has become more prevalent with the increased use of higher-strength materials in automotive applications. The first three images at left show how springback is com- pensated for in an automotive B-pillar through successive forming-simulation iterations, with the image at right showing the final part.

features and computation speeds,” says Mason, pointing out that this simulation program is particularly speedy compared to programs the company had used before.

“We can perform six to 10 itera- tions in a day on some parts where, before, we would get one,” he

explains.

Seven Walker employees in

Mason’s department conduct simulation—four AutoForm seats are used for simula- tions, with three more providing modeling sup- port such as unfolding and nesting of blanks. These seats also some- times perform simulation. Nine solvers support the sim-

ulation work.

In practice, Mason’s department

employs simulation from the start of a project, bringing a part into AutoForm to

Strength revealed.

Paulo makes your best parts even better.

Heat Treating Brazing

Metal Finishing

Trust us with your most critical heat treating projects.

Call 1 (866) 728-5648 or visit www.paulo.com for a quote today.

Headquarters

5711 West Park Ave

S

t. Louis, Missouri 6

nue 3110

44 MetalForming/April 2016

www.metalformingmagazine.com