Page 43 - MetalForming April 2016

P. 43

Retrofitness

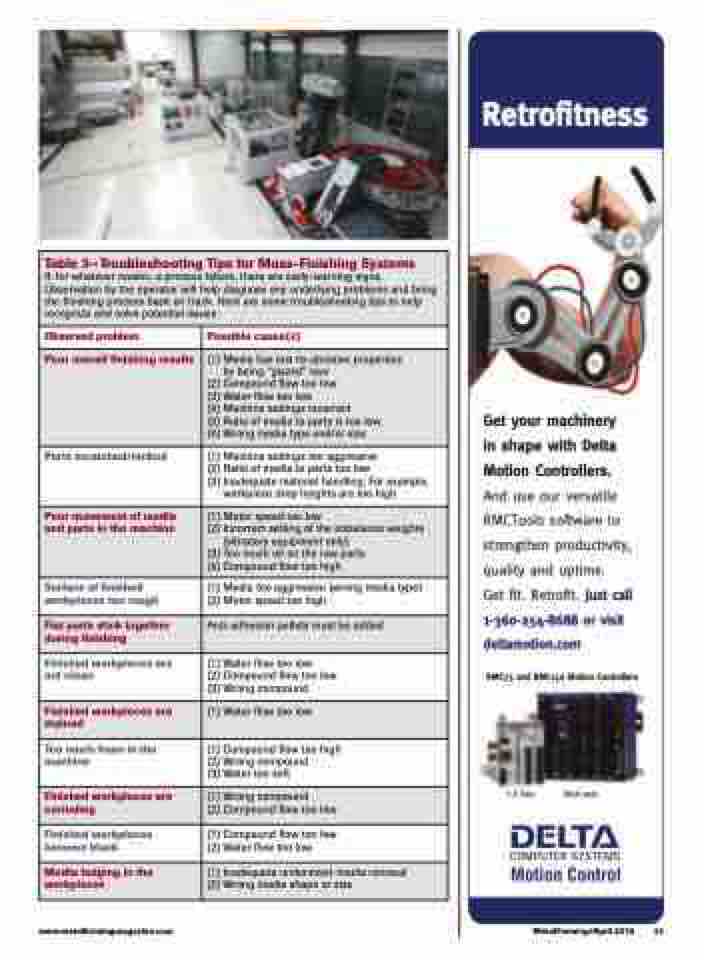

Table 3—Troubleshooting Tips for Mass-Finishing Systems

If, for whatever reason, a process falters, there are early-warning signs. Observation by the operator will help diagnose any underlying problems and bring the finishing process back on track. Here are some troubleshooting tips to help recognize and solve potential issues:

Observed problem

Possible cause(s)

Poor overall finishing results

(1) Media has lost its abrasive properties by being “glazed” over

(2) Compound flow too low

(3) Water flow too low

(4) Machine settings incorrect

(5) Ratio of media to parts is too low

(6) Wrong media type and/or size

Parts scratched/nicked

(1) Machine settings too aggressive

(2) Ratio of media to parts too low

(3) Inadequate material handling. For example,

workpiece drop heights are too high

Poor movement of media and parts in the machine

(1) Motor speed too low

(2) Incorrect setting of the imbalance weights

(vibratory equipment only)

(3) Too much oil on the raw parts

(4) Compound flow too high

Surface of finished workpieces too rough

(1) Media too aggressive (wrong media type) (2) Motor speed too high

Flat parts stick together during finishing

Anti-adhesion pellets must be added

Finished workpieces are not clean

(1) Water flow too low

(2) Compound flow too low (3) Wrong compound

Finished workpieces are stained

(1) Water flow too low

Too much foam in the machine

(1) Compound flow too high (2) Wrong compound

(3) Water too soft

Finished workpieces are corroding

(1) Wrong compound

(2) Compound flow too low

Finished workpieces become black

(1) Compound flow too low (2) Water flow too low

Media lodging in the workpieces

(1) Inadequate undersized-media removal (2) Wrong media shape or size

Get your machinery in shape with Delta Motion Controllers. And use our versatile RMCTools software to strengthen productivity, quality and uptime.

Get fit. Retrofit. Just call 1-360-254-8688 or visit deltamotion.com

RMC75 and RMC150 Motion Controllers

1-2 Axis Multi-axis

www.metalformingmagazine.com MetalForming/April 2016 41