Page 40 - MetalForming March 2016

P. 40

Turret Punch Presses

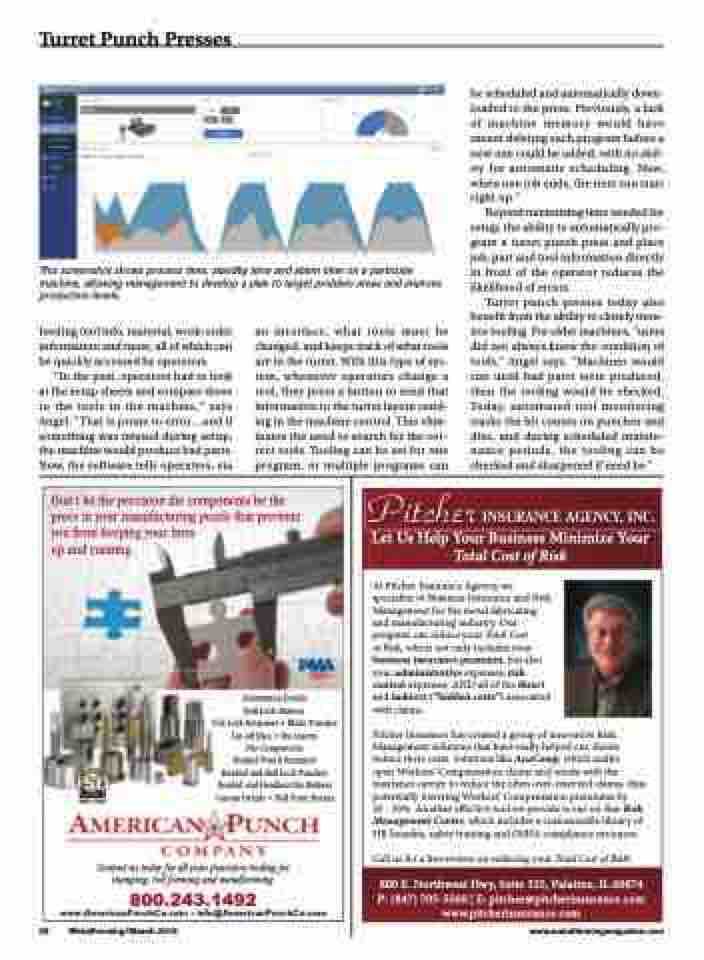

This screenshot shows process time, standby time and alarm time on a particular machine, allowing management to develop a plan to target problem areas and improve production levels.

be scheduled and automatically down- loaded to the press. Previously, a lack of machine memory would have meant deleting each program before a new one could be added, with no abil- ity for automatic scheduling. Now, when one job ends, the next can start right up.”

Beyond minimizing time needed for setup, the ability to automatically pro- gram a turret punch press and place job, part and tool information directly in front of the operator reduces the likelihood of errors.

Turret punch presses today also benefit from the ability to closely mon- itor tooling. For older machines, “users did not always know the condition of tools,” Angel says. “Machines would run until bad parts were produced, then the tooling would be checked. Today, automated tool monitoring tracks the hit counts on punches and dies, and during scheduled mainte- nance periods, the tooling can be checked and sharpened if need be.”

feeding tool info, material, work-order information and more, all of which can be quickly accessed by operators.

“In the past, operators had to look at the setup sheets and compare those to the tools in the machine,” says Angel. “That is prone to error...and if something was missed during setup, the machine would produce bad parts. Now, the software tells operators, via

an interface, what tools must be changed, and keeps track of what tools are in the turret. With this type of sys- tem, whenever operators change a tool, they press a button to send that information to the turret layout resid- ing in the machine control. This elim- inates the need to search for the cor- rect tools. Tooling can be set for one program, or multiple programs can

Don’t let the precision die components be the piece in your manufacturing puzzle that prevents you from keeping your lines

up and running.

Automation Details Ball Lock Buttons

a

B

B

all Lock Retainers • Blade Punches Cut-off Dies • Die Inserts

Die Components Headed Punch Retainers Headed and Ball Lock Punches

Headed and Headless Die Buttons

H

C

ustom Details • Roll Form Details

C

u

Contact us today for all your precision tooling for stamping, roll forming and metalforming.

800.243.1492

www.AmericanPunchCo.com • info@AmericanPunchCo.com

Let Us Help Your Business Minimize Your

Total Cost of Risk

38 MetalForming/March 2016

www.metalformingmagazine.com

At Pitcher Insurance Agency, we specialize in Business Insurance and Risk Management for the metal fabricating and manufacturing industry. Our program can reduce your Total Cost

of Risk, which not only includes your business insurance premium, but also your administrative expenses; risk control expenses; AND all of the direct and indirect (“hidden costs”) associated with claims.

Pitcher Insurance has created a group of innovative Risk Management solutions that have really helped our clients reduce their costs. Solutions like AcuComp, which audits

open Workers’ Compensation claims and works with the insurance carrier to reduce the often over-reserved claims, thus potentially lowering Workers’ Compensation premiums by

20 - 30%. Another effective tool we provide is our on-line Risk Management Center, which includes a customizable library of HR benefits, safety training and OSHA compliance resources.

Call us for a free review on reducing your Total Cost of Risk!

800 E. Northweat Hwy, Suite 325, Palatine, IL 60074 P: (847) 705-5560 | E: pitcher@pitcherinsurance.com www.pitcherinsurance.com