Page 26 - MetalForming January 2016

P. 26

Automation

Proclamation

Springboards Stamper to Prosperity

Two new coil-fed press lines—one progressive the other a transfer—help supply material to flexible robotic welding and assembly cells at Quality Metalcraft. The all-in approach to automation has led to significant growth for the one-time prototype/low-volume automotive supplier.

BY BRAD F. KUVIN, EDITOR

An aggressive approach to expan- sion into the low- to mid-vol- ume automotive supply chain has led metalformer Quality Metalcraft Corp., Livonia MI, to rapid and signif- icant growth. Previously focused on prototype work and specialty produc- tion, now QMC has expanded to sup- port mid-volume production stamp- ing and assembly work.

That evolution has hinged in large part on investments made early in 2015 when QMC commissioned two new press lines, a 600-ton progressive line and a 2500-ton transfer press. In just a few months, QMC had increased its booked capacity by 400 percent, and

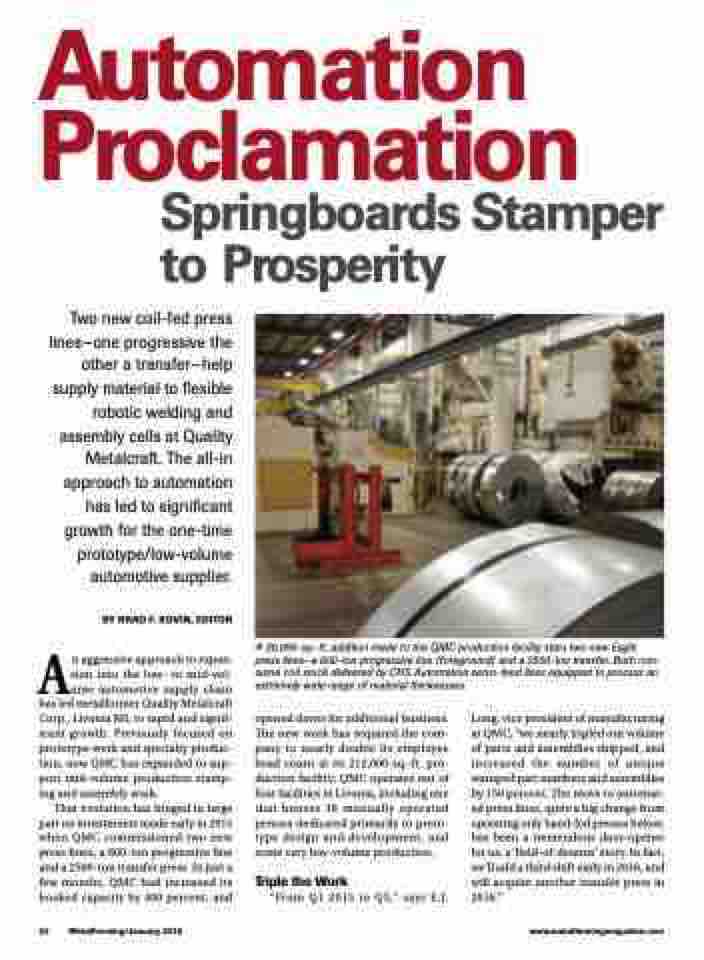

A 30,000-sq.-ft. addition made to the QMC production facility stars two new Eagle press lines—a 600-ton progressive line (foreground) and a 2500-ton transfer. Both con- sume coil stock delivered by CHS Automation servo-feed lines equipped to process an extremely wide range of material thicknesses.

24 MetalForming/January 2016

www.metalformingmagazine.com

opened doors for additional business. The new work has required the com- pany to nearly double its employee head count at its 212,000-sq.-ft. pro- duction facility; QMC operates out of four facilities in Livonia, including one that houses 38 manually operated presses dedicated primarily to proto- type design and development, and some very low-volume production.

Triple the Work

“From Q1 2015 to Q3,” says E.J.

Long, vice president of manufacturing at QMC, “we nearly tripled our volume of parts and assemblies shipped, and increased the number of unique stamped part numbers and assemblies by 150 percent. The move to automat- ed press lines, quite a big change from operating only hand-fed presses before, has been a tremendous door-opener for us, a ‘field-of-dreams’ story. In fact, we’ll add a third shift early in 2016, and will acquire another transfer press in 2016.”