Page 30 - MetalForming May 2015

P. 30

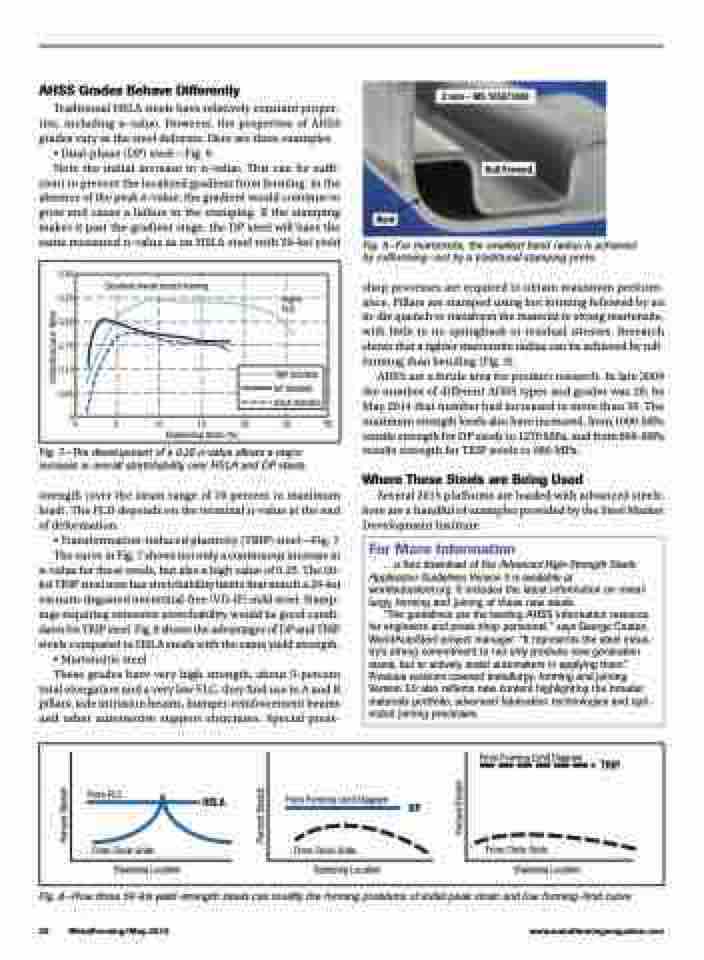

2 mm – MS 1050/1400

Roll Formed

Bent

AHSS Grades Behave Differently

Traditional HSLA steels have relatively constant proper- ties, including n-value. However, the properties of AHSS grades vary as the steel deforms. Here are three examples.

• Dual-phase (DP) steel—Fig. 6

Note the initial increase in n-value. This can be suffi- cient to prevent the localized gradient from forming. In the absence of the peak n-value, the gradient would continue to grow and cause a failure in the stamping. If the stamping makes it past the gradient stage, the DP steel will have the same measured n-value as an HSLA steel with 50-ksi yield

Fig. 9—For martensite, the smallest bend radius is achieved by rollforming—not by a traditional stamping press.

shop processes are required to obtain maximum perform- ance. Pillars are stamped using hot forming followed by an in-die quench to transform the material to strong martensite, with little to no springback or residual stresses. Research shows that a tighter martensite radius can be achieved by roll- forming than bending (Fig. 9).

AHSS are a fertile area for product research. In late 2009 the number of different AHSS types and grades was 28; by May 2014 that number had increased to more than 50. The maximum strength levels also have increased, from 1000-MPa tensile strength for DP steels to 1270 MPa, and from 800-MPa tensile strength for TRIP steels to 980 MPa.

Where These Steels are Being Used

Several 2015 platforms are loaded with advanced steels; here are a handful of examples provided by the Steel Market Development Institute.

0.30 0.25 0.20 0.15 0.10 0.05

0

0 5 10 15 20 25 30 Engineering Strain (%)

Excellent overall stretch forming

Higher FLD

TRI

P 350/600

DP 350/600 HSLA 350/450

Fig. 7—The development of a 0.25 n-value allows a major increase in overall stretchability over HSLA and DP steels.

strength (over the strain range of 10 percent to maximum load). The FLD depends on the terminal n-value at the end of deformation.

• Transformation-induced plasticity (TRIP) steel—Fig. 7

The curve in Fig. 7 shows not only a continuous increase in n-value for these steels, but also a high value of 0.25. The 50- ksi TRIP steel now has stretchability limits that match a 20-ksi vacuum-degassed interstitial-free (VD-IF) mild steel. Stamp- ings requiring extensive stretchability would be good candi- dates for TRIP steel. Fig. 8 shows the advantages of DP and TRIP steels compared to HSLA steels with the same yield strength.

• Martensitic steel

These grades have very high strength, about 5-percent total elongation and a very low FLC; they find use in A and B pillars, side intrusion beams, bumper-reinforcement beams and other automotive support structures. Special press-

For More Information

...a free download of the Advanced High-Strength Steels Application Guidelines Version 5 is available at worldautosteel.org. It includes the latest information on metal- lurgy, forming and joining of these new steels.

“The guidelines are the leading AHSS information resource for engineers and press shop personnel,” says George Coates, WorldAutoSteel project manager. “It represents the steel indus- try’s strong commitment to not only produce new generation steels, but to actively assist automakers in applying them.” Previous versions covered metallurgy, forming and joining. Version 5.0 also reflects new content highlighting the broader materials portfolio, advanced fabrication technologies and opti- mized joining processes.

From Forming Limit Diagram

From Circle Grids

TRIP

From FLC

From Circle Grids Stamping Location

HSLA

From Forming Limit Diagram

From Circle Grids

Stamping Location

DP

Stamping Location

Fig. 8—How three 50-ksi yield-strength steels can modify the forming problems of initial peak strain and low forming-limit curve.

28 MetalForming/May 2015 www.metalformingmagazine.com

Percent Stretch

Percent Stretch

Percent Stretch

Instantaneous n-Value