Page 28 - MetalForming May 2015

P. 28

Automotive Steels

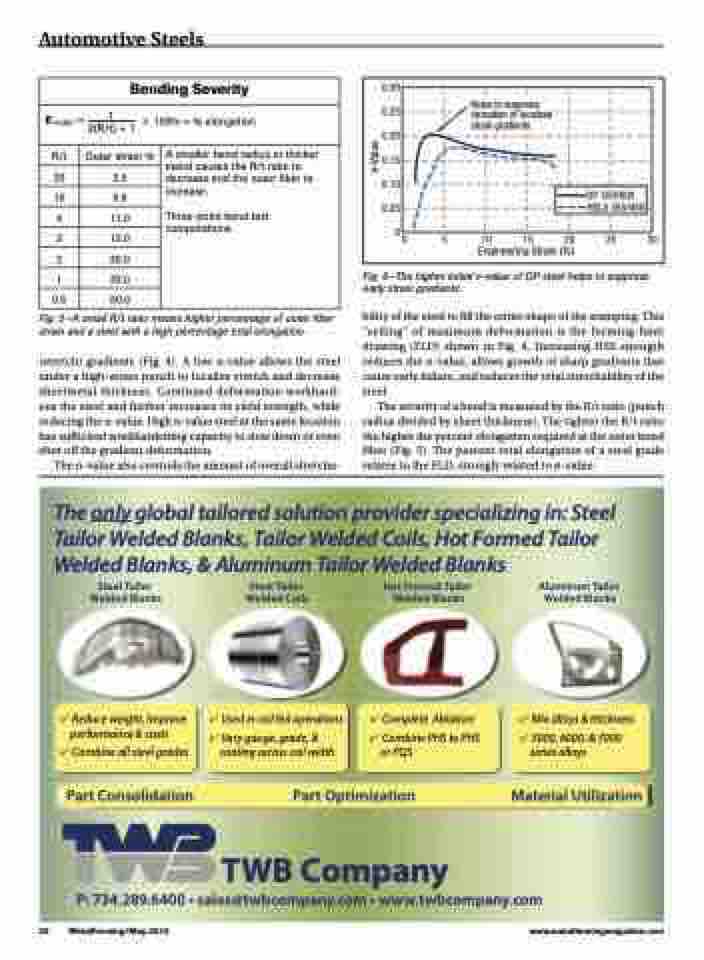

Bending Severity

outer = 1 100% = % elongation 2(R/t) + 1

R/t

Outer strain %

A smaller bend radius or thicker metal causes the R/t ratio to decrease and the outer fiber to increase.

Three-point bend test computations.

20

2.5

10

5.0

4

11.0

3

15.0

2

20.0

1

33.0

0.5

50.0

0.30 0.25 0.20 0.15 0.10 0.05

0

0 5 10 15 20 25 30 Engineering Strain (%)

Helps to suppress formation of localized strain gradients

DP 350/600 HSLA 350/450

Fig. 5—A small R/t ratio means higher percentage of outer fiber strain and a steel with a high percentage total elongation.

(stretch) gradients (Fig. 4). A low n-value allows the steel under a high-stress punch to localize stretch and decrease sheetmetal thickness. Continued deformation workhard- ens the steel and further increases its yield strength, while reducing the n-value. High n-value steel at the same location has sufficient workhardening capacity to slow down or even shut off the gradient deformation.

The n-value also controls the amount of overall stretcha-

Fig. 6—The higher initial n-value of DP steel helps to suppress early strain gradients.

bility of the steel to fill the entire shape of the stamping. This “ceiling” of maximum deformation is the forming-limit drawing (FLD) shown in Fig. 4. Increasing HSS strength reduces the n-value, allows growth of sharp gradients that cause early failure, and reduces the total stretchability of the steel.

The severity of a bend is measured by the R/t ratio (punch radius divided by sheet thickness). The tighter the R/t ratio the higher the percent elongation required at the outer bend fiber (Fig. 5). The percent total elongation of a steel grade relates to the FLD, strongly related to n-value.

The only global tailored solution provider specializing in: Steel

Tailor Welded Blanks, Tailor Welded Coils, Hot Formed Tailor Welded Blanks, & Aluminum Tailor Welded Blanks

Steel Tailor Welded Blanks

� Reduce weight, improve performance & costs

� Combine all steel grades Part Consolidation

Steel Tailor Welded Coils

� Used in coil fed operations � Vary gauge, grade, &

coating across coil width

Hot Formed Tailor Welded Blanks

� Complete Ablation � Combine PHS to PHS

or PQS

Aluminum Tailor Welded Blanks

� Mix alloys & thickness � 5000, 6000, & 7000

series alloys

Material Utilization

Part Optimization

TWB Company

26

MetalForming/May 2015 www.metalformingmagazine.com

P: 734.289.6400 • sales@twbcompany.com • www.twbcompany.com

n-Value