Page 27 - MetalForming May 2015

P. 27

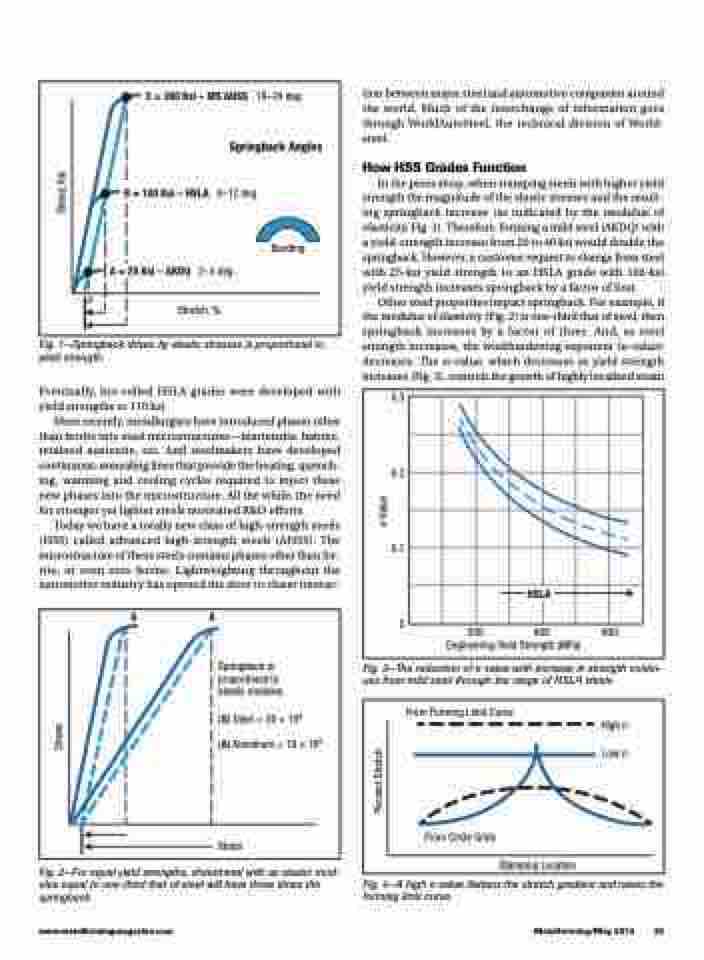

C = 200 Ksi – MS AHSS 16–24 deg.

Springback Angles

B = 100 Ksi – HSLA 8–12 deg.

A = 25 Ksi – AKDQ

2–3 deg. Stretch, %

Bending

Fig. 1—Springback driven by elastic stresses is proportional to yield strength.

Eventually, hot-rolled HSLA grades were developed with yield strengths to 110 ksi.

More recently, metallurgists have introduced phases other than ferrite into steel microstructures—martensite, bainite, retained austenite, etc. And steelmakers have developed continuous-annealing lines that provide the heating, quench- ing, warming and cooling cycles required to inject these new phases into the microstructure. All the while, the need for stronger yet lighter steels motivated R&D efforts.

Today we have a totally new class of high-strength steels (HSS) called advanced high-strength steels (AHSS). The microstructure of these steels contains phases other than fer- rite, or even zero ferrite. Lightweighting throughout the automotive industry has opened the door to closer interac-

tion between major steel and automotive companies around the world. Much of the interchange of information goes through WorldAutoSteel, the technical division of World- steel.

How HSS Grades Function

In the press shop, when stamping steels with higher yield strength the magnitude of the elastic stresses and the result- ing springback increase (as indicated by the modulus of elasticity, Fig. 1). Therefore, forming a mild steel (AKDQ) with a yield-strength increase from 20 to 40 ksi would double the springback. However, a customer request to change from steel with 25-ksi yield strength to an HSLA grade with 100-ksi yield strength increases springback by a factor of four.

Other steel properties impact springback. For example, if the modulus of elasticity (Fig. 2) is one-third that of steel, then springback increases by a factor of three. And, as steel strength increases, the workhardening exponent (n-value) decreases. The n-value, which decreases as yield strength increases (Fig. 3), controls the growth of highly localized strain

0.3

0.2

0.1

0

200 400 600 Engineering Yield Strength (MPa)

HSLA

SA

Springback is proportional to elastic modules.

(S)Steel=30×106

(A) Aluminum = 10 × 106

Strain

Fig. 2—For equal yield strengths, sheetmetal with an elastic mod- ulus equal to one-third that of steel will have three times the springback.

Fig. 4—A high n-value flattens the stretch gradient and raises the forming limit curve.

www.metalformingmagazine.com

MetalForming/May 2015 25

Fig. 3—The reduction of n-value with increase in strength contin- ues from mild steel through the range of HSLA steels.

From Forming Limit Curve

From Circle Grids

Stamping Location

High n Low n

Percent Stretch

n-Value

Stress

Stress, Ksi