Page 68 - MetalForming April 2015

P. 68

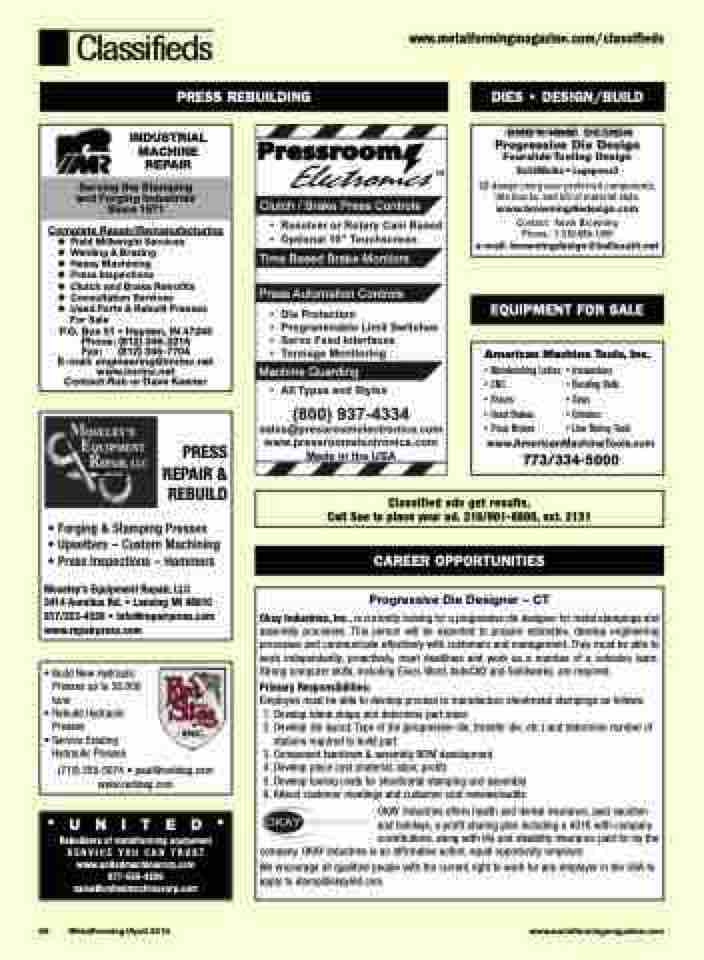

Classifieds

PRESS REBUILDING

www.metalformingmagazine.com/classifieds

DIES • DESIGN/BUILD

INDUSTRIAL MACHINE REPAIR

Serving the Stamping and Forging Industries Since 1971

Complete Repair/Remanufacturing

u Field Millwright Services u Welding & Brazing

u Heavy Machining

u Press Inspections

u Clutch and Brake Retrofits

u Consultation Services

u Used Parts & Rebuilt Presses

For Sale

P.O. Box 51 • Hayden, IN 47245

Phone: (812) 346-2216

Fax: (812) 346-7704 E-mail: engineering@imrinc.net www.imrinc.net Contact Rob or Dave Keener

Clutch / Brake Press Controls

� ������������������������ � ����������������������

Time Based Brake Monitors Press Automation Controls

� �������������

� ������������������������� � �������������������

� �����������������

Machine Guarding

� �����������������

����� �������� ������������������������������ ���������������������������� ���� �� ��� ���

Classified ads get results.

Call Sue to place your ad. 216/901-8800, ext. 2131

Progressive Die Design FourslideTooling Design

SolidWorks • Logopress3

3D design using your preferred components, title blocks, and bill of material style. www.browningdiedesign.com Contact: Kevin Browning

Phone: 1-270-684-1050

e-mail: browningdesign@bellsouth.net

EQUIPMENT FOR SALE

American Machine Tools, Inc.

• Metalworking Lathes • CNC

• Shears

• Hand Brakes

• Press Brakes

• Ironworkers

• Bending Rolls

• Saws

• Grinders

• Line Boring Tools

PRESS REPAIR & REBUILD

• Forging & Stamping Presses

• Upsetters – Custom Machining • Press Inspections – Hammers

Moseley’s Equipment Repair, LLC

3414 Aurelius Rd. • Lansing MI 48910 517/323-4520 • info@repairpress.com www.repairpress.com

www.AmericanMachineTools.com

773/334-5000

CAREER OPPORTUNITIES

Progressive Die Designer – CT

Okay Industries, Inc., is currently looking for a progressive die designer for metal stampings and assembly processes. This person will be expected to prepare estimates, develop engineering processes and communicate effectively with customers and management. They must be able to work independently, proactively, meet deadlines and work as a member of a cohesive team. Strong computer skills, including Excel, Word, AutoCAD and Solidworks, are required.

Primary Responsibilities:

Employee must be able to develop process to manufacture sheetmetal stampings as follows:

1. Develop blank shape and determine part mass

2. Develop die layout: Type of die (progressive die, transfer die, etc.) and determine number of

stations required to build part

3. Component teardown & assembly BOM development

4. Develop piece cost (material, labor, profit)

5. Develop tooling costs for sheetmetal stamping and assembly

6. Attend customer meetings and customer cost reviews/audits

OKAY Industries offers health and dental insurance, paid vacation and holidays, a profit sharing plan including a 401K with company contributions, along with life and disability insurance paid for by the

company. OKAY Industries is an affirmative action, equal opportunity employer.

We encourage all qualified people with the current right to work for any employer in the USA to apply to stamp@okayind.com.

• Build New Hydraulic Presses up to 20,000 tons

• Rebuild Hydraulic Presses

• Service Existing Hydraulic Presses

(715) 258-5074 • paul@redstag.com www.redstag.com

*UNITED*

Rebuilders of metalforming equipment SERVICE YOU CAN TRUST www.unitedmachinecorp.com 877-556-4209 sales@unitedmachinecorp.com

66 MetalForming/April 2015

www.metalformingmagazine.com