Page 42 - MetalForming July 2014

P. 42

Tooling by Design

Explosive charge

Vacuum (1)

Gas bubble forms

Clamps Die

Vacuum line

Shock wave

Plume from gas bubble

(3)

Unlike SPF, explosive forming can be used with any aluminum alloy, with AA1100-O recognized as the most formable alloy (ASM Spe- cialty Handbook: Aluminum and Aluminum Alloys).

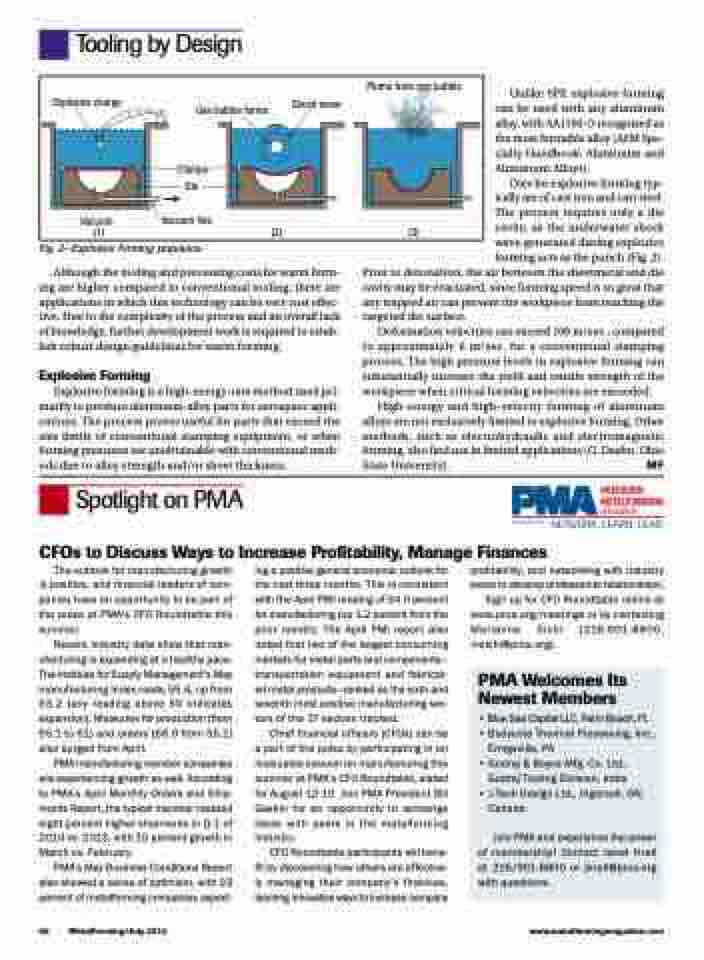

Dies for explosive forming typ- ically are of cast iron and cast steel. The process requires only a die cavity, as the underwater shock wave generated during explosive forming acts as the punch (Fig. 2).

Fig. 2—Explosive forming sequence

Although the tooling and processing costs for warm form- ing are higher compared to conventional tooling, there are applications in which this technology can be very cost effec- tive. Due to the complexity of the process and an overall lack of knowledge, further development work is required to estab- lish robust design guidelines for warm forming.

Explosive Forming

Explosive forming is a high-energy-rate method used pri- marily to produce aluminum-alloy parts for aerospace appli- cations. The process proves useful for parts that exceed the size limits of conventional stamping equipment, or when forming pressures are unobtainable with conventional meth- ods due to alloy strength and/or sheet thickness.

Spotlight on PMA

Prior to detonation, the air between the sheetmetal and die cavity may be evacuated, since forming speed is so great that any trapped air can prevent the workpiece from reaching the targeted die surface.

Deformation velocities can exceed 100 m/sec., compared to approximately 6 m/sec. for a conventional stamping process. The high pressure levels in explosive forming can substantially increase the yield and tensile strength of the workpiece when critical forming velocities are exceeded.

High-energy and high-velocity forming of aluminum alloys are not exclusively limited to explosive forming. Other methods, such as electrohydraulic and electromagnetic forming, also find use in limited applications (G. Daehn, Ohio State University). MF

(2)

CFOs to Discuss Ways to Increase Profitability, Manage Finances

The outlook for manufacturing growth is positive, and financial leaders of com- panies have an opportunity to be part of the pulse at PMA’s CFO Roundtable this summer.

ing a positive general economic outlook for the next three months. This is consistent with the April PMI reading of 54.9 percent for manufacturing (up 1.2 percent from the prior month). The April PMI report also noted that two of the largest consuming markets for metal parts and components— transportation equipment and fabricat- ed metal products—ranked as the sixth and seventh most positive manufacturing sec- tors of the 17 sectors tracked.

profitability, and networking with industry peers to develop professional relationships. Sign up for CFO Roundtable online at www.pma.org/meetings or by contacting Marianne Sichi (216-901-8800,

Recent industry data show that man- ufacturing is expanding at a healthy pace. The Institute for Supply Management’s May manufacturing index reads 55.4, up from 53.2 (any reading above 50 indicates expansion). Measures for production (from 55.1 to 61) and orders (56.9 from 55.1) also surged from April.

msichi@pma.org).

PMA Welcomes Its

Newest Members

• Blue Sea Capital LLC, Palm Beach, FL • Bodycote Thermal Processing, Inc.,

Emigsville, PA

• Godrej & Boyce Mfg. Co. Ltd.,

Godrej Tooling Division, India

• J-Tech Design Ltd., Ingersoll, ON,

Canada

Join PMA and experience the power of membership! Contact Janet Krall at 216/901-8800 or jkrall@pma.org with questions.

PMA manufacturing member companies are experiencing growth as well. According to PMA’s April Monthly Orders and Ship- ments Report, the typical member realized eight-percent higher shipments in Q-1 of 2014 vs. 2013, with 10 percent growth in March vs. February.

Chief financial officers (CFOs) can be a part of the pulse by participating in an invaluable session on manufacturing this summer at PMA’s CFO Roundtable, slated for August 12-13. Join PMA President Bill Gaskin for an opportunity to exchange ideas with peers in the metalforming industry.

PMA’s May Business Conditions Report also showed a sense of optimism, with 93 percent of metalforming companies expect-

CFO Roundtable participants will bene- fit by discovering how others are effective- ly managing their company’s finances, learning innovative ways to increase company

40 MetalForming/July 2014

www.metalformingmagazine.com