Page 22 - MetalForming November 2013

P. 22

The CNC Punch Press Productivity Push

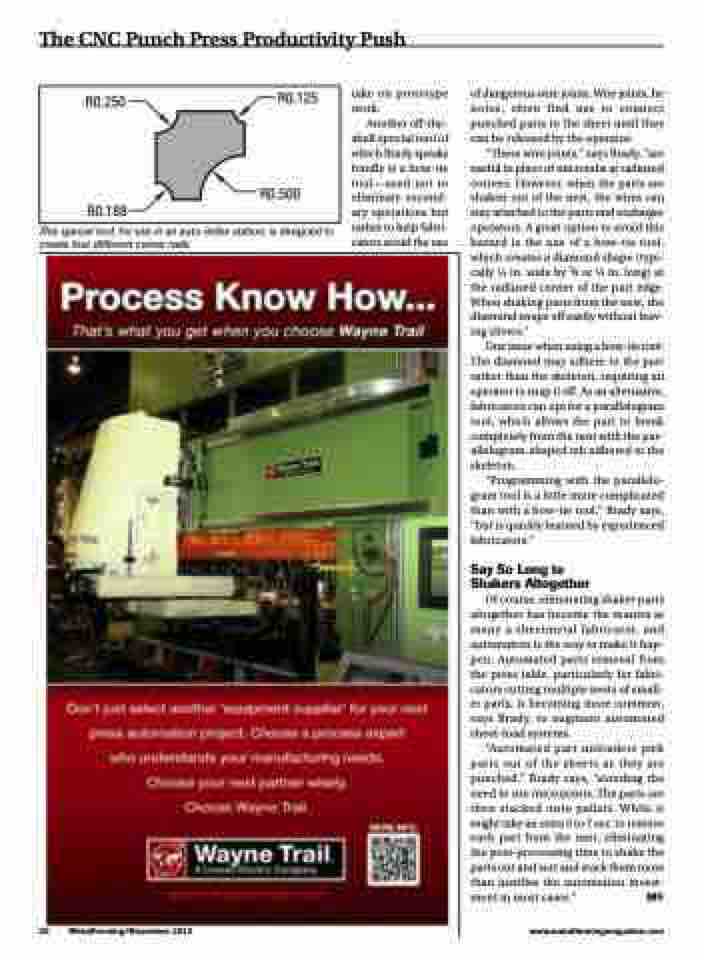

R0.250

R0.188

R0.125

R0.500

This special tool, for use in an auto-index station, is designed to create four different corner radii.

take on prototype work.

Another off-the- shelf special tool of which Brady speaks fondly is a bow-tie tool—used not to eliminate second- ary operations but rather to help fabri- cators avoid the use

of dangerous wire joints. Wire joints, he notes, often find use to connect punched parts to the sheet until they can be released by the operator.

“These wire joints,” says Brady, “are useful in place of microtabs at radiused corners. However, when the parts are shaken out of the nest, the wires can stay attached to the parts and endanger operators. A great option to avoid this hazard is the use of a bow-tie tool, which creates a diamond shape (typi- cally 1⁄4 in. wide by 3⁄8 or 1⁄2 in. long) at the radiused corner of the part edge. When shaking parts from the nest, the diamond snaps off easily without leav- ing slivers.”

One issue when using a bow-tie tool: The diamond may adhere to the part rather than the skeleton, requiring an operator to snap it off. As an alternative, fabricators can opt for a parallelogram tool, which allows the part to break completely from the nest with the par- allelogram-shaped tab adhered to the skeleton.

“Programming with the parallelo- gram tool is a little more complicated than with a bow-tie tool,” Brady says, “but is quickly learned by experienced fabricators.”

Say So Long to Shakers Altogether

Of course, eliminating shaker parts altogether has become the mantra at many a sheetmetal fabricator, and automation is the way to make it hap- pen. Automated parts removal from the press table, particularly for fabri- cators cutting multiple nests of small- er parts, is becoming more common, says Brady, to augment automated sheet-load systems.

“Automated part unloaders pick parts out of the sheets as they are punched,” Brady says, “avoiding the need to use microjoints. The parts are then stacked onto pallets. While it might take an extra 5 to 7 sec. to remove each part from the nest, eliminating the post-processing time to shake the parts out and sort and stack them more than justifies the automation invest- ment in most cases.” MF

20 MetalForming/November 2013

www.metalformingmagazine.com