Page 21 - MetalForming November 2013

P. 21

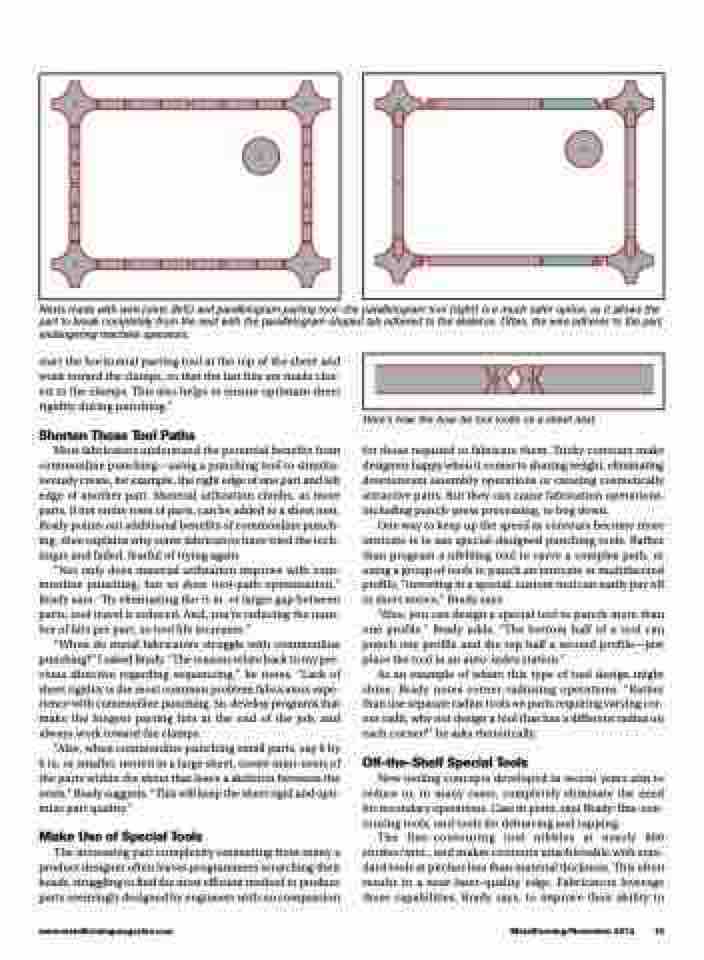

Nests made with wire joints (left) and parallelogram parting tool—the parallelogram tool (right) is a much safer option, as it allows the part to break completely from the nest with the parallelogram-shaped tab adhered to the skeleton. Often, the wire adheres to the part, endangering machine operators.

start the horizontal parting tool at the top of the sheet and work toward the clamps, so that the last hits are made clos- est to the clamps. This also helps to ensure optimum sheet rigidity during punching.”

Shorten Those Tool Paths

Most fabricators understand the potential benefits from commonline punching—using a punching tool to simulta- neously create, for example, the right edge of one part and left edge of another part. Material utilization climbs, as more parts, if not entire rows of parts, can be added to a sheet nest. Brady points out additional benefits of commonline punch- ing, then explains why some fabricators have tried the tech- nique and failed, fearful of trying again.

“Not only does material utilization improve with com- monline punching, but so does tool-path optimization,” Brady says. “By eliminating the 1⁄2 in. or larger gap between parts, tool travel is reduced. And, you’re reducing the num- ber of hits per part, so tool life increases.”

“When do metal fabricators struggle with commonline punching?” I asked Brady. “The reasons relate back to my pre- vious directive regarding sequencing,” he notes. “Lack of sheet rigidity is the most common problem fabricators expe- rience with commonline punching. So, develop programs that make the longest parting hits at the end of the job, and always work toward the clamps.

“Also, when commonline punching small parts, say 6 by 6 in. or smaller, nested in a large sheet, create mini-nests of the parts within the sheet that leave a skeleton between the nests,” Brady suggests. “This will keep the sheet rigid and opti- mize part quality.”

Make Use of Special Tools

The increasing part complexity emanating from many a product designer often leaves programmers scratching their heads, struggling to find the most efficient method to produce parts seemingly designed by engineers with no compassion

Here’s how the bow-tie tool looks on a sheet nest.

for those required to fabricate them. Tricky contours make designers happy when it comes to shaving weight, eliminating downstream assembly operations or creating cosmetically attractive parts. But they can cause fabrication operations, including punch-press processing, to bog down.

One way to keep up the speed as contours become more intricate is to use special-designed punching tools. Rather than program a nibbling tool to carve a complex path, or using a group of tools to punch an intricate or multifaceted profile, “investing in a special, custom tool can easily pay off in short notice,” Brady says.

“Also, you can design a special tool to punch more than one profile,” Brady adds. “The bottom half of a tool can punch one profile and the top half a second profile—just place the tool in an auto-index station.”

As an example of where this type of tool design might shine, Brady notes corner-radiusing operations. “Rather than use separate radius tools on parts requiring varying cor- ner radii, why not design a tool that has a different radius on each corner?” he asks rhetorically.

Off-the-Shelf Special Tools

New tooling concepts developed in recent years aim to reduce or, in many cases, completely eliminate the need for secondary operations. Case in point, says Brady: fine-con- touring tools, and tools for deburring and tapping.

The fine-contouring tool nibbles at nearly 800 strokes/min., and makes contours unachievable with stan- dard tools at pitches less than material thickness. This often results in a near-laser-quality edge. Fabricators leverage these capabilities, Brady says, to improve their ability to

www.metalformingmagazine.com

MetalForming/November 2013 19