Page 24 - MetalForming November 2013

P. 24

Proper

Air Filtration–

See No Evil, Hear No Evil

Noise and haze can add stress unnecessarily to already taxed welders and machine operators. Why inhibit their productivity when all that’s needed is a well-designed and properly installed air-filtration system—precisely the case at this agricultural-equipment OEM.

BY BRAD F. KUVIN, EDITOR

Welders and cutting-machine operators welcome with open arms new technology that makes their days more productive, safe, rewarding and enjoyable. But such joy and appreciation can quickly subside when improved productivity and throughput comes with added shop noise and dirtier air.

Such was the case at agricultural- industry supplier Fast Manufacturing, Mountain Lake, MN, a manufacturer of pull-type sprayers and liquid-fertilizer application equipment. As the market for such equipment has surged since 2008, according to Fast general manager Clay Roll, so has the firm’s fabrication and welding capacity.

In 2009 the firm added 4800 sq. ft. to its main fabrication building, which houses 25 manual arc-welding booths. In 2011, a second adjoining produc- tion facility welcomed a new plasma- arc-cutting table, and in January 2012 a new 4500-W laser-cutting machine. Finally, in December of 2012 the firm acquired a second 4500-W laser-cutting machine, replacing the plasma table. And, a third adjoining building fea- tures a 4000-W laser-cutting machine designed to cut tubes and structural sections. Fast processes structural-steel plate and sheet 16 gauge to 2 in. thick, and tube 3⁄4- to 10-in. square.

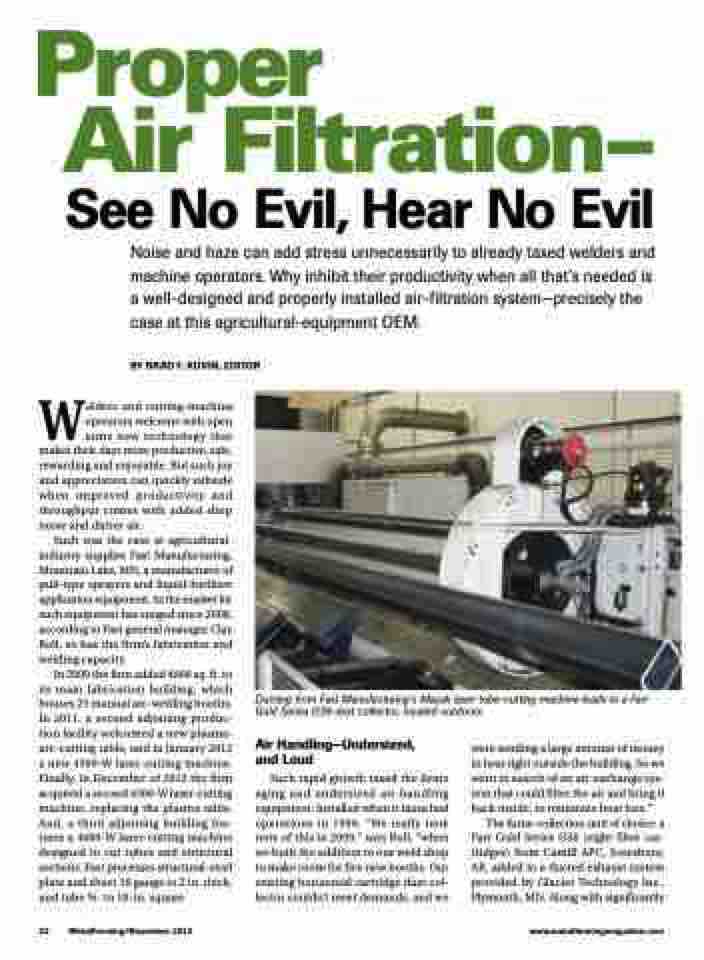

Ducting from Fast Manufacturing’s Mazak laser tube-cutting machine leads to a Farr Gold Series GS8 dust collector, located outdoors.

22 MetalForming/November 2013

www.metalformingmagazine.com

Air Handling—Undersized, and Loud

Such rapid growth taxed the firm’s aging and undersized air-handling equipment, installed when it launched operations in 1990. “We really took note of this in 2009,” says Roll, “when we built the addition to our weld shop to make room for five new booths. Our existing horizontal cartridge dust col- lector couldn’t meet demands, and we

were sending a large amount of money in heat right outside the building. So we went in search of an air-exchange sys- tem that could filter the air and bring it back inside, to minimize heat loss.”

The fume-collection unit of choice: a Farr Gold Series GS8 (eight filter car- tridges) from Camfil APC, Jonesboro, AR, added to a ducted exhaust system provided by Glacier Technology Inc., Plymouth, MN. Along with significantly