Page 78 - MetalForming October 2013

P. 78

76

MetalForming/October 2013

www.metalformingmagazine.com

• •

• •

Specialty Stainless & High Temperature Alloys In-house leveling, shearing, laser cutting, slitting & edging

Experienced sales staff Online ordering

Stainless Steel:

17-4 302

17-7 303

301 304/304L 3011⁄4 316/316L 3011⁄2 321 301FH 347

410 416 430 440 446

Nickel Alloys:

A-286 263

625

718 X750 800 H/HT Alloy X

Cobalt Alloys:

188 L605

Prodec® Plate:

304/L 316/L

If You...

BEND it PUNCH it FOLD it FORM it

LASER it DRAW it ROLL it CUT it

WE’VE GOT IT!

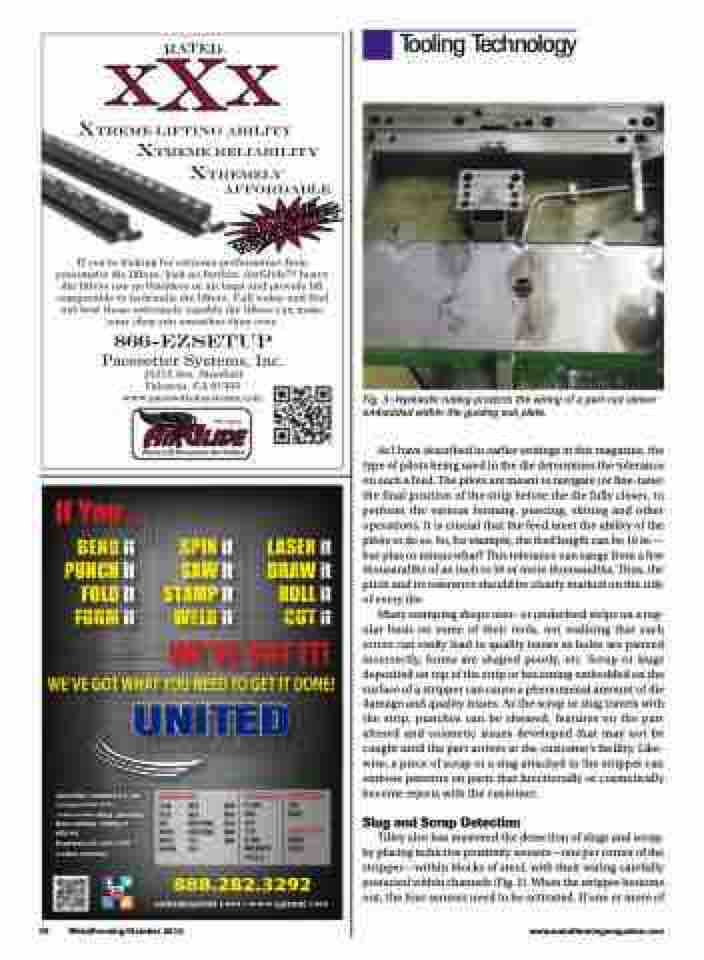

Fig. 3—Hydraulic tubing protects the wiring of a part-out sensor embedded within the guiding exit plate.

As I have described in earlier writings in this magazine, the type of pilots being used in the die determines the tolerance on such a feed. The pilots are meant to navigate (or fine-tune) the final position of the strip before the die fully closes, to perform the various forming, piercing, slitting and other operations. It is crucial that the feed meet the ability of the pilots to do so. So, for example, the feed length can be 10 in.— but plus or minus what? This tolerance can range from a few thousandths of an inch to 50 or more thousandths. Thus, the pitch and its tolerance should be clearly marked on the side of every die.

Many stamping shops over- or underfeed strips on a reg- ular basis on some of their tools, not realizing that such errors can easily lead to quality issues as holes are pierced incorrectly, forms are shaped poorly, etc. Scrap or slugs deposited on top of the strip or becoming embedded on the surface of a stripper can cause a phenomenal amount of die damage and quality issues. As the scrap or slug travels with the strip, punches can be sheared, features on the part altered and cosmetic issues developed that may not be caught until the part arrives at the customer’s facility. Like- wise, a piece of scrap or a slug attached to the stripper can emboss patterns on parts that functionally or cosmetically become rejects with the customer.

Slug and Scrap Detection

Tilley also has mastered the detection of slugs and scrap, by placing inductive proximity sensors—one per corner of the stripper—within blocks of steel, with their wiring carefully protected within channels (Fig. 2). When the stripper bottoms out, the four sensors need to be activated. If one or more of

SPIN it

SAW it STAMP it WELD it

WE’VE GOT WHAT YOU NEED TO GET IT DONE!

888.282.3292

sales@upmet.com • www.upmet.com

Tooling Technology