Page 76 - MetalForming October 2013

P. 76

Tooling Technology

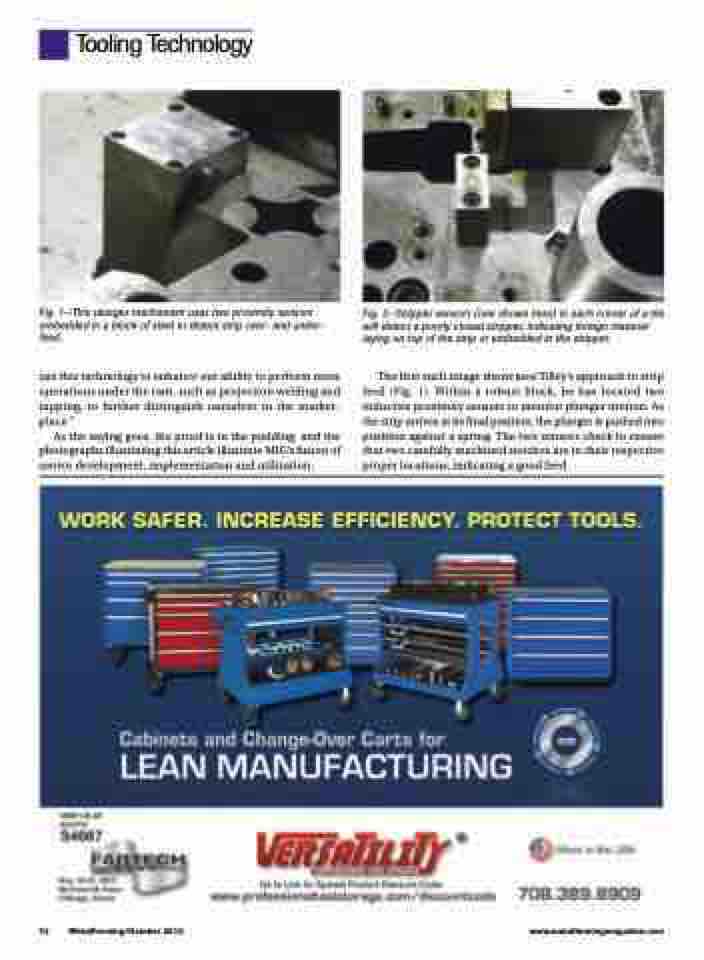

Fig. 1—This plunger mechanism uses two proximity sensors embedded in a block of steel to detect strip over- and under- feed.

use this technology to enhance our ability to perform more operations under the ram, such as projection welding and tapping, to further distinguish ourselves in the market- place.”

As the saying goes, the proof is in the pudding, and the photographs illustrating this article illustrate MIG’s fusion of sensor development, implementation and utilization.

Fig. 2—Stripper sensors (one shown here) in each corner of a die will detect a poorly closed stripper, indicating foreign material laying on top of the strip or embedded in the stripper.

The first such image showcases Tilley’s approach to strip feed (Fig. 1). Within a robust block, he has located two inductive proximity sensors to monitor plunger motion. As the strip arrives at its final position, the plunger is pushed into position against a spring. The two sensors check to ensure that two carefully machined notches are in their respective proper locations, indicating a good feed.

74 MetalForming/October 2013

www.metalformingmagazine.com