Page 54 - MetalForming July 2013

P. 54

The Science of Forming By Stuart Keeler

Tooling Technology

Forming Steel—The Positive and the Negative

900 800 700 600 500 400 300

200

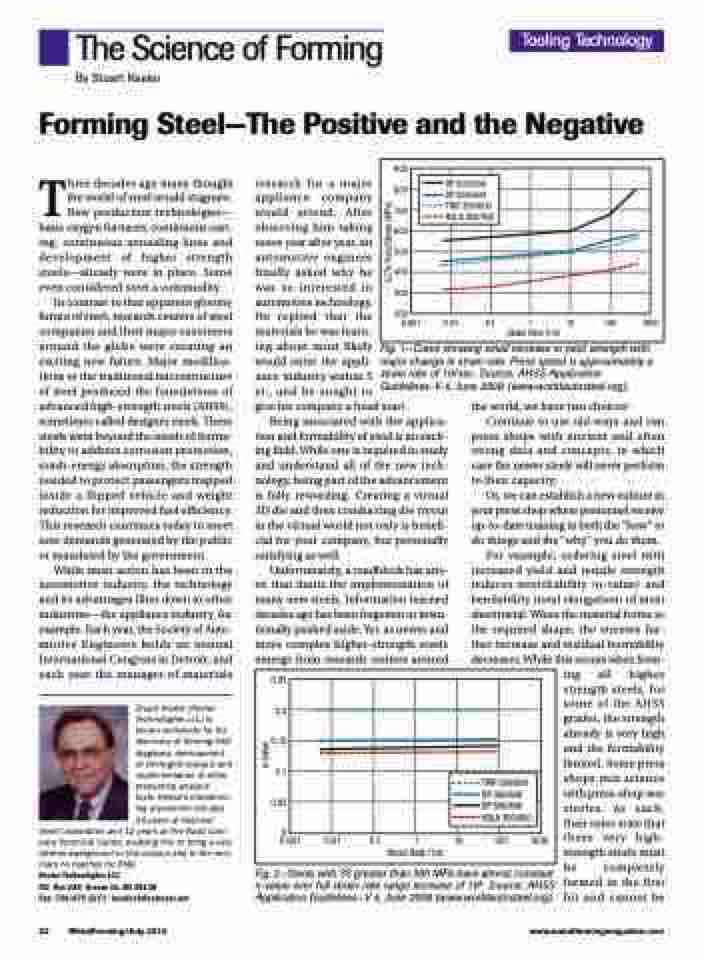

0.001 0.01

0.1 1 10 Strain Rate (1/s)

100 1000

DP 500/800 DP 350/600 TRIP 350/600 HSLA 350/450

Three decades ago many thought the world of steel would stagnate. New production technologies— basic oxygen furnaces, continuous cast- ing, continuous annealing lines and development of higher strength steels—already were in place. Some even considered steel a commodity.

In contrast to that apparent gloomy future of steel, research centers of steel companies and their major customers around the globe were creating an exciting new future. Major modifica- tions to the traditional microstructure of steel produced the foundations of advanced high-strength steels (AHSS), sometimes called designer steels. These steels went beyond the needs of forma- bility to address corrosion protection, crash-energy absorption, the strength needed to protect passengers trapped inside a flipped vehicle and weight reduction for improved fuel efficiency. This research continues today to meet new demands generated by the public or mandated by the government.

While most action has been in the automotive industry, the technology and its advantages filter down to other industries—the appliance industry, for example. Each year, the Society of Auto- motive Engineers holds an annual International Congress in Detroit, and each year the manager of materials

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementation of other press-shop analysis

tools. Keeler’s metalform- ing experience includes 24 years at National

Steel Corporation and 12 years at The Budd Com- pany Technical Center, enabling him to bring a very diverse background to this column and to the sem- inars he teaches for PMA.

Keeler Technologies LLC

P.O. Box 283, Grosse Ile, MI 48138

Fax: 734/671-2271 • keeltech@comcast.net

research for a major appliance company would attend. After observing him taking

notes year after year, an automotive engineer finally asked why he

was so interested in automotive technology.

He replied that the materials he was learn-

ing about most likely

would enter the appli-

ance industry within 5

yr., and he sought to

give his company a head start.

Being associated with the applica- tion and formability of steel is an excit- ing field. While one is required to study and understand all of the new tech- nology, being part of the advancement is fully rewarding. Creating a virtual 3D die and then conducting die tryout in the virtual world not only is benefi- cial for your company, but personally satisfying as well.

Unfortunately, a roadblock has aris- en that limits the implementation of many new steels. Information learned decades ago has been forgotten or inten- tionally pushed aside. Yet, as newer and more complex higher-strength steels emerge from research centers around

Fig. 1—Curve showing small increase in yield strength with major change in strain rate. Press speed is approximately a strain rate of 10/sec. Source: AHSS Application Guidelines–V 4, June 2008 (www.worldautosteel.org).

52 MetalForming/July 2013

www.metalformingmagazine.com

Fig. 2—Steels with YS greater than 300 MPa have almost constant n-value over full strain-rate range increase of 104. Source: AHSS Application Guidelines—V 4, June 2008 (www.worldautosteel.org).

ing all higher strength steels, for some of the AHSS grades, the strength already is very high and the formability limited. Some press shops mix science with press-shop war stories. As such, their rules state that these very high- strength steels must be completely formed in the first hit and cannot be

the world, we have two choices: Continue to use old ways and run press shops with ancient and often wrong data and concepts, in which case the newer steels will never perform

to their capacity;

Or, we can establish a new culture in

your press shop where personnel receive up-to-date training in both the “how” to do things and the “why” you do them.

For example, ordering steel with increased yield and tensile strength reduces stretchability (n-value) and bendability (total elongation) of most sheetmetal. When the material forms to the required shape, the stresses fur- ther increase and residual formability decreases. While this occurs when form-

0.25 0.2 0.15 0.1 0.05

0

0.001 0.01

0.1 1 10 Strain Rate (1/s)

100 1000

TRIP 350/600 DP 350/600 DP 500/800 HSLA 350/450

n-Value

0.2% Yield Stress (MPa)