Page 37 - MetalForming May 2013

P. 37

The Science of Forming

70 60 50 40 30 20 10

0

45 (310) ksi (MPa)

Yield Strength 55 (380) 65 (450)

80 (550)

Center of Original Circles

Maximum Allowable Stretch

DP

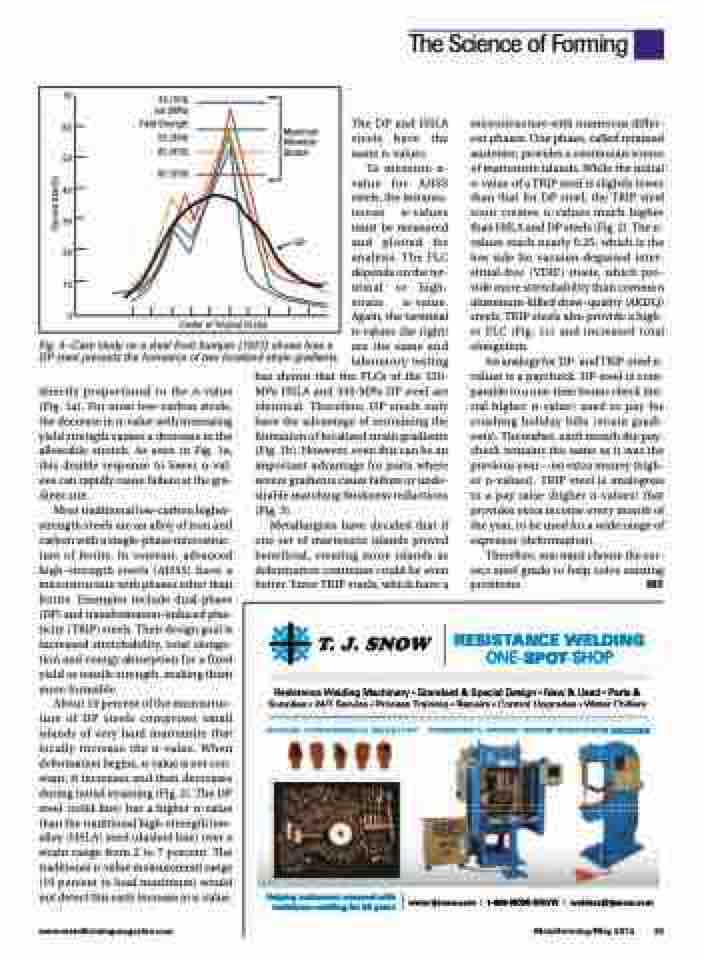

Fig. 3—Case study on a steel front bumper (1977) shows how a DP steel prevents the formation of two localized strain gradients.

The DP and HSLA steels have the same n-values.

To measure n- value for AHSS steels, the instanta- neous n-values must be measured and plotted for analysis. The FLC depends on the ter- minal or high- strain n-value. Again, the terminal n-values (far right) are the same and laboratory testing

microstructure with numerous differ- ent phases. One phase, called retained austenite, provides a continuous source of martensite islands. While the initial n-value of a TRIP steel is slightly lower than that for DP steel, the TRIP steel soon creates n-values much higher than HSLA and DP steels (Fig. 2). The n- values reach nearly 0.25, which is the low side for vacuum-degassed inter- stitial-free ( VDIF) steels, which pro- vide more stretchability than common aluminum-killed draw-quality (AKDQ) steels. TRIP steels also provide a high- er FLC (Fig. 1c) and increased total elongation.

An analogy for DP- and TRIP-steel n- values is a paycheck. DP steel is com- parable to a one-time bonus check (ini- tial higher n-value) used to pay for crushing holiday bills (strain gradi- ents). Thereafter, each month the pay- check remains the same as it was the previous year—no extra money (high- er n-values). TRIP steel is analogous to a pay raise (higher n-values) that provides extra income every month of the year, to be used for a wide range of expenses (deformation).

Therefore, one must choose the cor- rect steel grade to help solve existing problems. MF

directly proportional to the n-value (Fig. 1a). For most low-carbon steels, the decrease in n-value with increasing yield strength causes a decrease in the allowable stretch. As seen in Fig. 1a, this double response to lower n-val- ues can rapidly cause failure at the gra- dient site.

Most traditional low-carbon higher- strength steels are an alloy of iron and carbon with a single-phase microstruc- ture of ferrite. In contrast, advanced high-strength steels (AHSS) have a microstructure with phases other than ferrite. Examples include dual-phase (DP) and transformation-induced plas- ticity (TRIP) steels. Their design goal is increased stretchability, total elonga- tion and energy absorption for a fixed yield or tensile strength, making them more formable.

About 10 percent of the microstruc- ture of DP steels comprises small islands of very hard martensite that locally increase the n-value. When deformation begins, n-value is not con- stant; it increases and then decreases during initial straining (Fig. 2). The DP steel (solid line) has a higher n-value than the traditional high-strength low- alloy (HSLA) steel (dashed line) over a strain range from 2 to 7 percent. The traditional n-value measurement range (10 percent to load maximum) would not detect this early increase in n-value.

has shown that the FLCs of the 350- MPa HSLA and 350-MPa DP steel are identical. Therefore, DP steels only have the advantage of restraining the formation of localized strain gradients (Fig. 1b). However, even this can be an important advantage for parts where severe gradients cause failure or unde- sirable matching thickness reductions (Fig. 3).

Metallurgists have decided that if one set of martensite islands proved beneficial, creating more islands as deformation continues could be even better. Enter TRIP steels, which have a

RESISTANCE WELDING ONE-SPOT-SHOP

& Supplies • 24/7 Service • Process Training • Repairs • Control Upgrades • Water Chillers

DIVERSE CONSUMABLES INVENTORY STANDARD & SPECIAL DESIGN RESISTANCE WELDERS

Resistance Welding M

Ma

ac

ch

hi

in

ne

er

ry

y•

•S

St

ta

an

nd

da

ar

rd

d&

&S

Sp

pe

ec

ci

ia

al

lD

De

es

s

si

ig

gn

n •

• N

Ne

ew

w &

& U

Us

se

ed

d •

• P

Pa

ar

rt

ts

s &

Helping customers succeed with resistance welding for 50 years

www.tjsnow.com | 1-800-NOW-SNOW | welders@tjsnow.com

www.metalformingmagazine.com

MetalForming/May 2013 35

Percent Stretch