Page 36 - MetalForming May 2013

P. 36

The Science of Forming By Stuart Keeler

The Complex Properties

of Advanced High-Strength Steels

Tooling Technology

Mechanical properties of steel grades have been used for decades to determine their capacity for forming, structural uti- lization, in-service performance and part life. The most common proper- ties, obtained from a tensile test, are yield strength ( YS), ultimate tensile strength (UTS), uniform elongation (UE) and total elongation ( TE). Previ- ous research has been focused on improving the consistency of these properties through improved steel- making and pro-

cessing.

During the late

1930s, researchers

discovered that

the rate of work

hardening (n-

value) contributed

significantly to the

stretching capac-

ity of steel. During

the ’50s and ’60s,

research docu-

mented the broad impact of work hard- ening on metalforming. Many in the metalforming industry now consider n- value as a very important tensile-test property.

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementation of other press-shop analysis

tools. Keeler’s metalform- ing experience includes 24 years at National

Steel Corporation and 12 years at The Budd Com- pany Technical Center, enabling him to bring a very diverse background to this column and to the sem- inars he teaches for PMA.

Keeler Technologies LLC P.O. Box 283

Grosse Ile, MI 48138 Fax: 734/671-2271 keeltech@comcast.net

Work hardening is measured from the tensile-test stress-strain curve for the elongation range of 10 to 20 per- cent, or more accurately from 10 per- cent to load maximum (uniform elon- gation). The n-value is derived from the slope of log true stress plotted against log true strain for the power law stress-strain equation. For most traditional low-carbon low- and high- strength steels, n-value for a given coil remains constant during deformation. However, metallurgical processes used

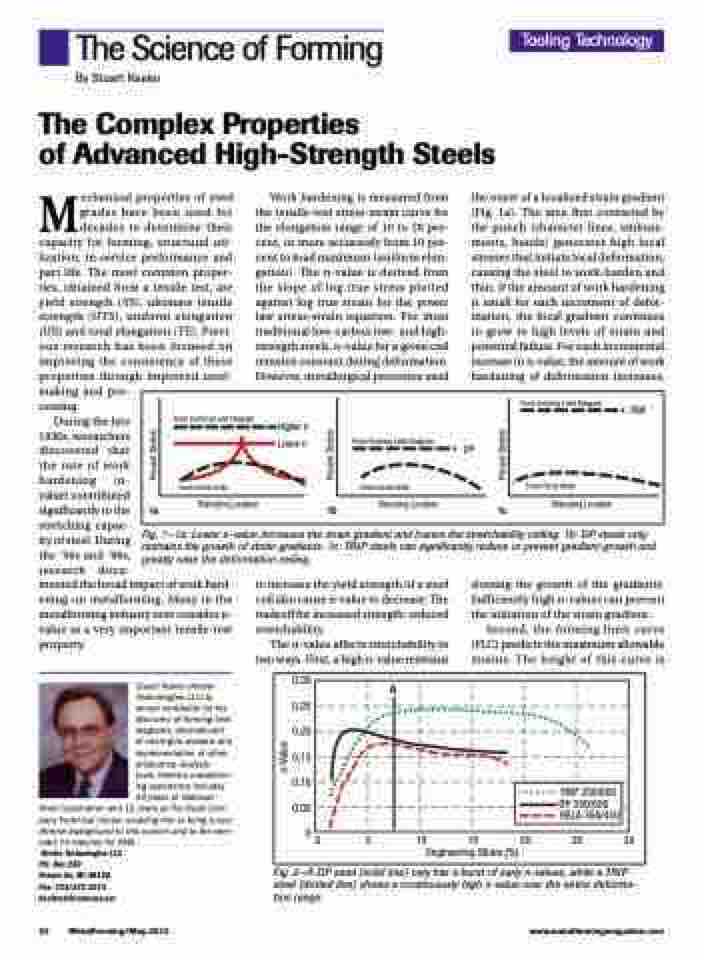

the onset of a localized strain gradient (Fig. 1a). The area first contacted by the punch (character lines, emboss- ments, bends) generates high local stresses that initiate local deformation, causing the steel to work-harden and thin. If the amount of work hardening is small for each increment of defor- mation, the local gradient continues to grow to high levels of strain and potential failure. For each incremental increase in n-value, the amount of work hardening of deformation increases,

From Forming Limit Diagram

From Circle Grids

Stamping Location

TRIP

From Forming Limit Diagram

From Circle Grids

Higher n

Lower n

From Forming Limit Diagram

From Circle Grids

DP

Stamping Location

Stamping Location

1a 1b 1c

Fig. 1—1a: Lower n-value increases the strain gradient and lowers the stretchability ceiling. 1b: DP steels only restrains the growth of strain gradients. 1c: TRIP steels can significantly reduce or prevent gradient growth and greatly raise the deformation ceiling.

to increase the yield strength of a steel coil also cause n-value to decrease. The tradeoff for increased strength: reduced stretchability.

The n-value affects stretchability in two ways. First, a high n-value restrains

slowing the growth of the gradients. Sufficiently high n-values can prevent the initiation of the strain gradient.

Second, the forming limit curve (FLC) predicts the maximum allowable strains. The height of this curve is

0.30 0.25 0.20 0.15 0.10 0.05

00 5 10 15 20 25 30 Engineering Strain (%)

A

TRIP 350/600

DP 350/600 HSLA 350/450

34 MetalForming/May 2013

www.metalformingmagazine.com

Fig. 2—A DP steel (solid line) only has a burst of early n-values, while a TRIP steel (dotted line) shows a continuously high n-value over the entire deforma- tion range.

n-Value

Percent Stretch

Percent Stretch

Percent Stretch