Page 30 - MetalForming May 2013

P. 30

Servo-Driven Press

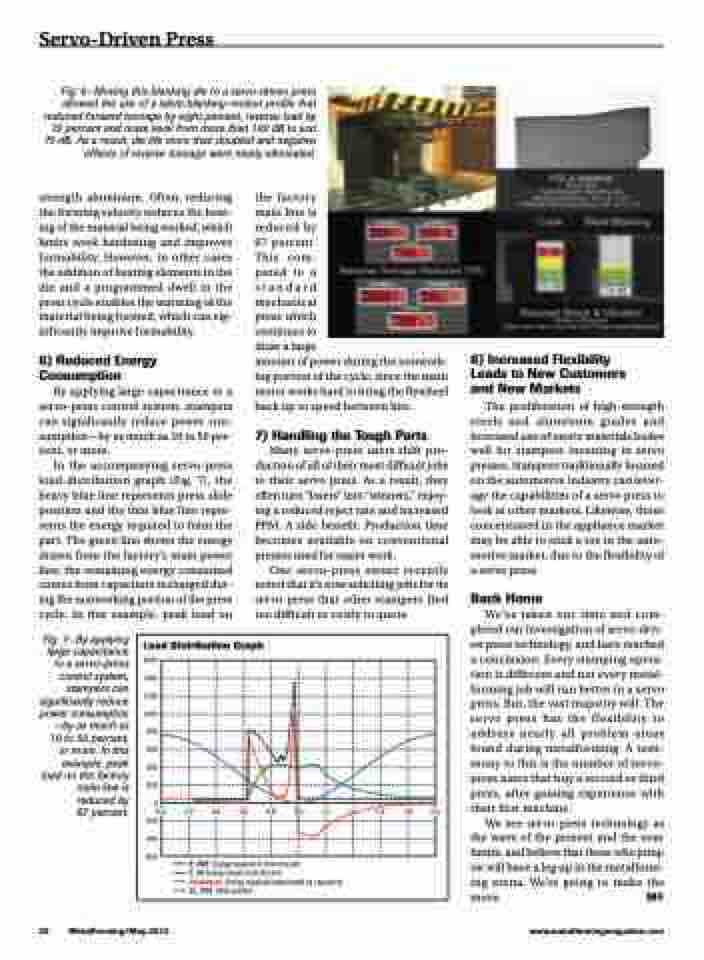

Fig. 6—Moving this blanking die to a servo-driven press

allowed the use of a silent blanking-motion profile that reduced forward tonnage by eight percent, reverse load by 72 percent and noise level from more than 100 dB to just 75 dB. As a result, die life more than doubled and negative effects of reverse tonnage were nearly eliminated.

strength aluminum. Often, reducing the forming velocity reduces the heat- ing of the material being worked, which limits work hardening and improves formability. However, in other cases the addition of heating elements in the die and a programmed dwell in the press cycle enables the warming of the material being formed, which can sig- nificantly improve formability.

6) Reduced Energy Consumption

By applying large capacitance to a servo-press control system, stampers can significantly reduce power con- sumption—by as much as 10 to 50 per- cent, or more.

In the accompanying servo-press load-distribution graph (Fig. 7), the heavy blue line represents press slide position and the thin blue line repre- sents the energy required to form the part. The green line shows the energy drawn from the factory’s main power line; the remaining energy consumed comes from capacitors recharged dur- ing the nonworking portion of the press cycle. In this example, peak load on

Fig. 7—By applying large capacitance to a servo-press control system, stampers can significantly reduce power consumption —by as much as 10 to 50 percent, or more. In this example, peak load on the factory main line is reduced by 67 percent.

the factory

main line is

reduced by

67 percent.

This com-

pared to a

standard

mechanical

press which

continues to

draw a large

amount of power during the nonwork- ing portion of the cycle, since the main motor works hard to bring the flywheel back up to speed between hits.

7) Handling the Tough Parts

Many servo-press users shift pro- duction of all of their most difficult jobs to their servo press. As a result, they often turn “losers” into “winners,” enjoy- ing a reduced reject rate and increased PPM. A side benefit: Production time becomes available on conventional presses used for easier work.

One servo-press owner recently noted that it’s now soliciting jobs for its servo press that other stampers find too difficult or costly to quote.

8) Increased Flexibility Leads to New Customers and New Markets

The proliferation of high-strength steels and aluminum grades and increased use of exotic materials bodes well for stampers investing in servo presses. Stampers traditionally focused on the automotive industry can lever- age the capabilities of a servo press to look at other markets. Likewise, those concentrated in the appliance market may be able to stick a toe in the auto- motive market, due to the flexibility of a servo press.

Back Home

We’ve taken our time and com- pleted our investigation of servo-driv- en press technology, and have reached a conclusion. Every stamping opera- tion is different and not every metal- forming job will run better in a servo press. But, the vast majority will. The servo press has the flexibility to address nearly all problem areas found during metalforming. A testi- mony to this is the number of servo- press users that buy a second or third press, after gaining experience with their first machine.

We see servo-press technology as the wave of the present and the near future, and believe that those who jump on will have a leg up in the metalform- ing arena. We’re going to make the move. MF

Load Distribution Graph

1600 1400 1200 1000

800 600 400 200

0

0.0 0.2 0.4

0.6 0.8 1.0

1.2 1.4

1.6 1.8 2.0

–200 –400 –600

P_OUT: Energy required to form the part

P_IN: Energy drawn from the line

Condensor: Energy supplied/regenerated by capacitors SL_POS: Slide position

28 MetalForming/May 2013

www.metalformingmagazine.com