Page 37 - MetalForming January 2013

P. 37

0.3

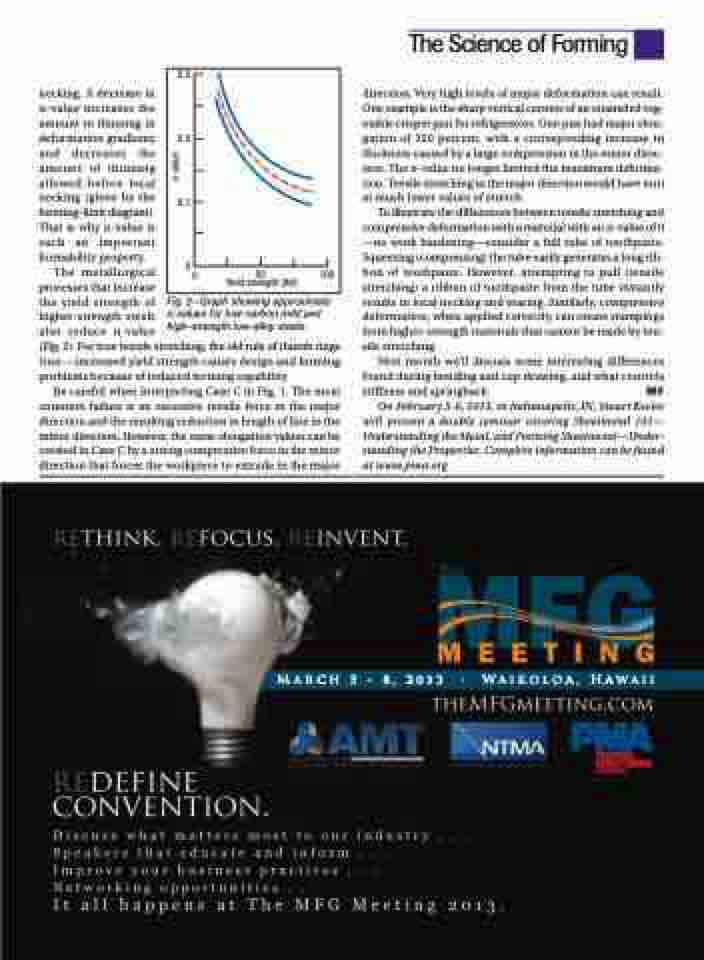

necking. A decrease in n-value increases the amount to thinning in deformation gradients and decreases the amount of thinning allowed before local necking (given by the forming-limit diagram). That is why n-value is such an important formability property.

The metallurgical

processes that increase

the yield strength of

higher-strength steels

also reduce n-value

(Fig. 2). For true tensile stretching, the old rule of thumb rings true-—increased yield strength causes design and forming problems because of reduced forming capability.

Be careful when interpreting Case C in Fig. 1. The most common failure is an excessive tensile force in the major direction and the resulting reduction in length of line in the minor direction. However, the same elongation values can be created in Case C by a strong compressive force in the minor direction that forces the workpiece to extrude in the major

direction. Very high levels of major deformation can result. One example is the sharp vertical corners of an enameled veg- etable crisper pan for refrigerators. One pan had major elon- gation of 320 percent, with a corresponding increase in thickness caused by a large compression in the minor direc- tion. The n-value no longer limited the maximum deforma- tion. Tensile stretching in the major direction would have torn at much lower values of stretch.

To illustrate the differences between tensile stretching and compressive deformation with a material with an n-value of 0 —no work hardening—consider a full tube of toothpaste. Squeezing (compressing) the tube easily generates a long rib- bon of toothpaste. However, attempting to pull (tensile stretching) a ribbon of toothpaste from the tube instantly results in local necking and tearing. Similarly, compressive deformation, when applied correctly, can create stampings from higher-strength materials that cannot be made by ten- sile stretching.

Next month we’ll discuss some interesting differences found during bending and cup drawing, and what controls stiffness and springback. MF

On February 5-6, 2013, in Indianapolis, IN, Stuart Keeler will present a double seminar covering Sheetmetal 101— Understanding the Metal, and Forming Sheetmetal—Under- standing the Properties. Complete information can be found at www.pma.org.

0.2

0.1

00 50 100 Yield strength (Ksi)

Fig. 2—Graph showing approximate n-values for low-carbon mild and high-strength low-alloy steels.

The Science of Forming

n value

March 5 - 8, 2013 · Waikoloa, Hawaii