Page 35 - MetalForming November 2012

P. 35

The Science of Forming

50

40

30 A 20

10

Location

Location B

001234567 Depth of Stamping (in.)

50 40 30 20 10

Location A

Draw Bead

Location B

No Draw Bead

001234567 Depth of Stamping (in.)

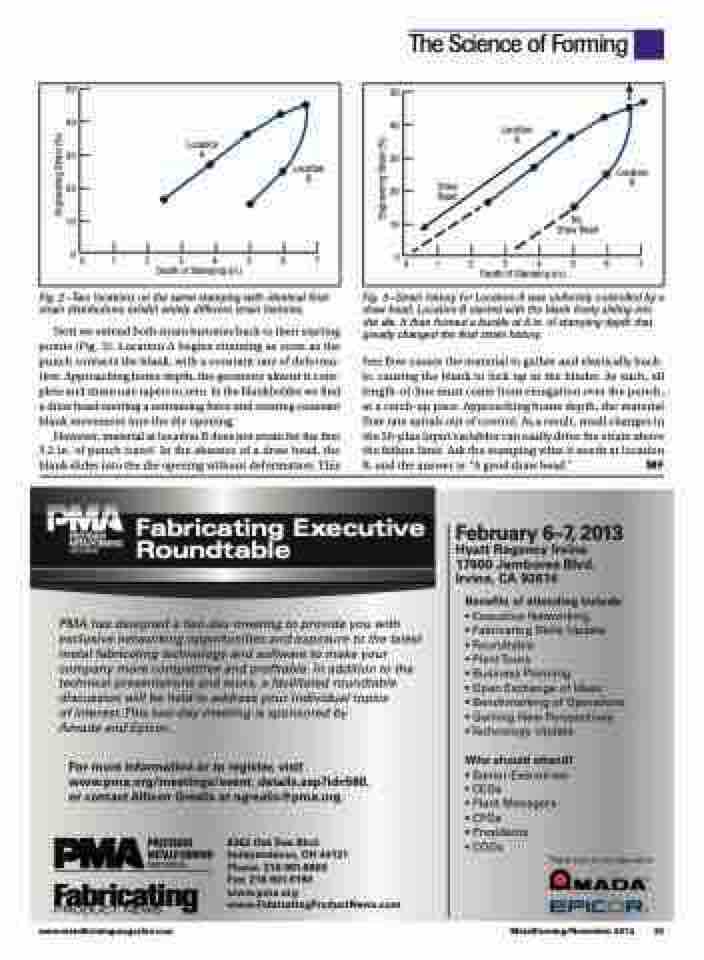

Fig. 2—Two locations on the same stamping with identical final strain distributions exhibit widely different strain histories.

Next we extend both strain histories back to their starting points (Fig. 3). Location A begins straining as soon as the punch contacts the blank, with a constant rate of deforma- tion. Approaching home depth, the geometry almost is com- plete and strain rate tapers to zero. In the blankholder we find a draw bead exerting a restraining force and creating constant blank movement into the die opening.

However, material at location B does not strain for the first 3.2 in. of punch travel. In the absence of a draw bead, the blank slides into the die opening without deformation. This

Fig. 3—Strain history for Location A was uniformly controlled by a draw bead. Location B started with the blank freely sliding into the die. It then formed a buckle at 6 in. of stamping depth that greatly changed the final strain history.

free flow causes the material to gather and elastically buck- le, causing the blank to lock up in the binder. As such, all length-of-line must come from elongation over the punch, at a catch-up pace. Approaching home depth, the material flow rate spirals out of control. As a result, small changes in the 50-plus input variables can easily drive the strain above the failure limit. Ask the stamping what it needs at location B, and the answer is: “A good draw bead.” MF

Fabricating Executive Roundtable

PMA has designed a two-day meeting to provide you with exclusive networking opportunities and exposure to the latest metal fabricating technology and software to make your company more competitive and profitable. In addition to the technical presentations and tours, a facilitated roundtable discussion will be held to address your individual topics

of interest.This two-day meeting is sponsored by Amada and Epicor.

For more information or to register, visit www.pma.org/meetings/event_details.asp?id=580, or contact Allison Grealis at agrealis@pma.org.

February 6–7, 2013 Hyatt Regency Irvine 17900 Jamboree Blvd. Irvine, CA 92614

Benefits of attending include:

• Executive Networking

• Fabricating Skills Update

• Roundtable

• PlantTours

• Business Planning

• Open Exchange of Ideas

• Benchmarking of Operations • Gaining New Perspectives •Technology Update

Who should attend?

• Senior Executives • CEOs

• Plant Managers

• CFOs

6363 OakTree Blvd.

Independence, OH 44131

Phone: 216-901-8800

Fax: 216-901-9190

www.pma.org www.FabricatingProductNews.com

• Presidents • COOs

Thank you to our sponsors

Fabricating

PRODUCT NEWS

www.metalformingmagazine.com

MetalForming/November 2012 33

Engineering Strain (%)

Engineering Strain (%)