Page 31 - MetalForming November 2012

P. 31

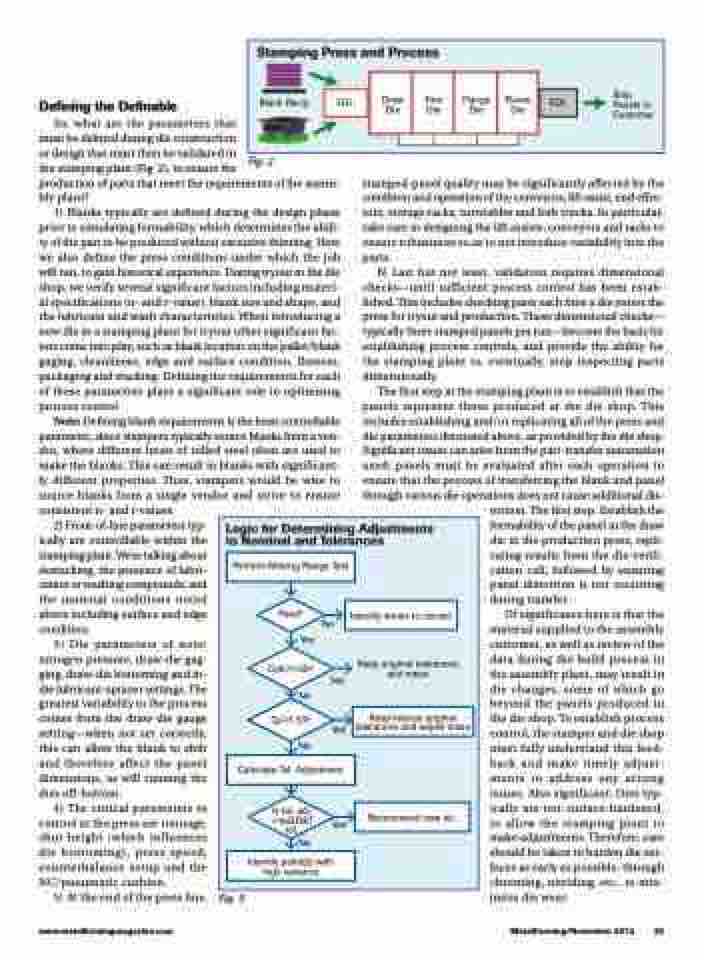

Stamping Press and Process

Blank Rec’g

Ship Panels to Customer

FOL

Draw Die

Trim Die

Flange Die

Pierce Die

EOL

Defining the Definable

So, what are the parameters that

must be defined during die construction

or design that must then be validated in Fig. 2

the stamping plant (Fig. 2), to ensure the

production of parts that meet the requirements of the assem- bly plant?

1) Blanks typically are defined during the design phase prior to simulating formability, which determines the abili- ty of the part to be produced without excessive thinning. Here we also define the press conditions under which the job will run, to gain historical experience. During tryout in the die shop, we verify several significant factors including materi- al specifications (n- and r-value), blank size and shape, and the lubricant and wash characteristics. When introducing a new die in a stamping plant for tryout other significant fac- tors come into play, such as blank location on the pallet/blank gaging, cleanliness, edge and surface condition, flatness, packaging and stacking. Defining the requirements for each of these parameters plays a significant role in optimizing process control.

Note: Defining blank requirements is the least controllable parameter, since stampers typically source blanks from a ven- dor, where different heats of rolled steel often are used to make the blanks. This can result in blanks with significant- ly different properties. Thus, stampers would be wise to source blanks from a single vendor and strive to ensure consistent n- and r-values.

stamped-panel quality may be significantly affected by the condition and operation of the conveyors, lift assist, end effec- tors, storage racks, turntables and fork trucks. In particular, take care in designing the lift assists, conveyors and racks to ensure robustness so as to not introduce variability into the parts.

6) Last but not least, validation requires dimensional checks—until sufficient process control has been estab- lished. This includes checking parts each time a die enters the press for tryout and production. These dimensional checks— typically three stamped panels per run—become the basis for establishing process controls, and provide the ability for the stamping plant to, eventually, stop inspecting parts dimensionally.

The first step at the stamping plant is to establish that the panels represent those produced at the die shop. This includes establishing and/or replicating all of the press and die parameters discussed above, as provided by the die shop. Significant issues can arise from the part-transfer automation used; panels must be evaluated after each operation to ensure that the process of transferring the blank and panel through various die operations does not cause additional dis-

tortion. The first step: Establish the formability of the panel in the draw die in the production press, repli- cating results from the die-verifi- cation cell, followed by ensuring panel distortion is not occurring during transfer.

Of significance here is that the material supplied to the assembly customer, as well as review of the data during the build process in the assembly plant, may result in die changes, some of which go beyond the panels produced in the die shop. To establish process control, the stamper and die shop must fully understand this feed- back and make timely adjust- ments to address any arising issues. Also significant: Dies typ- ically are not surface-hardened, to allow the stamping plant to make adjustments. Therefore, care should be taken to harden die sur- faces as early as possible, through chroming, nitriding, etc., to min- imize die wear.

Logic for Determining Adjustments to Nominal and Tolerances

Perform Moving Range Test

Pass?

No

Yes

Cpk>1.00?

Yes

No

Cp>1.33?

Yes

No

Keep original tolerances and mean

Identify issues to correct

Keep/reduce original tolerances and adjust mean

Calculate Tol. Adjustment

Is tol. adj. 4xGD&T tol.

Yes No

Recommend new tol.

Identify point(s) with high variance

2) Front-of-line parameters typ- ically are controllable within the stamping plant. We’re talking about destacking, the presence of lubri- cation or washing compounds, and the material conditions noted above including surface and edge condition.

3) Die parameters of note: nitrogen pressure, draw-die gag- ging, draw-die bottoming and in- die lubricant-sprayer settings. The greatest variability to the process comes from the draw-die gauge setting—when not set correctly, this can allow the blank to shift and therefore affect the panel dimensions, as will running the dies off-bottom.

4) The critical parameters to control at the press are tonnage, shut height (which influences die bottoming), press speed, counterbalance setup and the NC/pneumatic cushion.

5) At the end of the press line,

Fig. 3

www.metalformingmagazine.com

MetalForming/November 2012 29