Page 25 - MetalForming November 2012

P. 25

Invented by Salvagnini.

Perfected by Salvagnini.

Introducing the competition’s nightmare – the newest, fastest

laser cutter from the company that created the category. The Salvagnini L5.

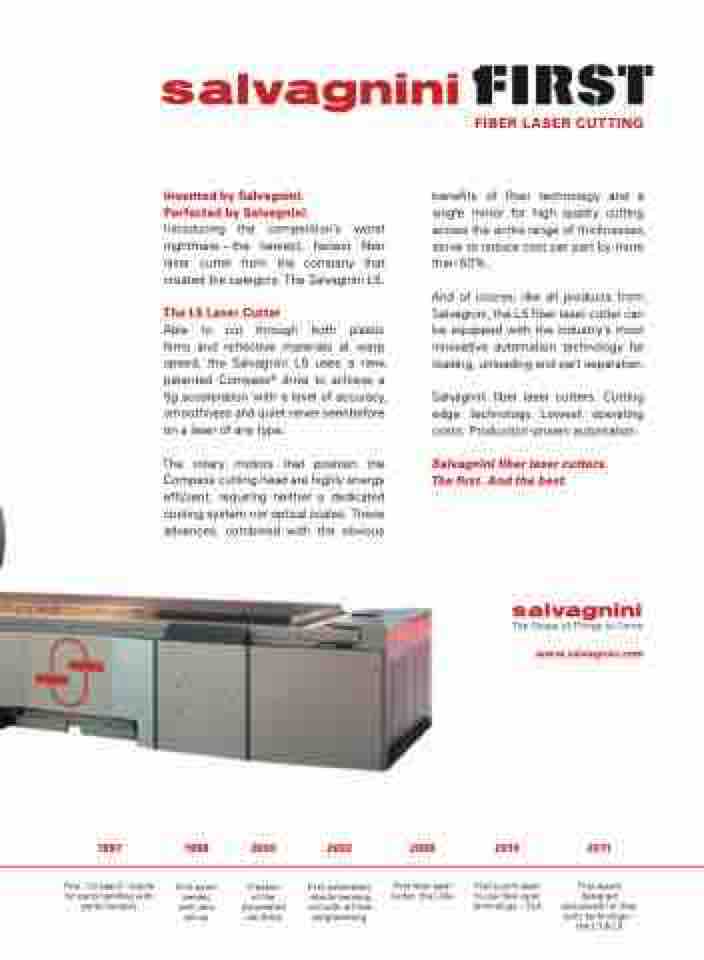

The L5 Laser Cutter

Able to cut through both plastic films and reflective materials at warp speed, the Salvagnini L5 uses a new, patented Compass® drive to achieve a 5g acceleration with a level of accuracy, smoothness and quiet never seenbefore on a laser of any type.

The rotary motors that position the Compass cutting head are highly energy efficient, requiring neither a dedicated cooling system nor optical scales. These advances, combined with the obvious

FIBER LASER CUTTING

benefits of fiber technology and a single mirror for high quality cutting across the entire range of thicknesses, serve to reduce cost per part by more than 50%.

And of course, like all products from Salvagnini, the L5 fiber laser cutter can be equipped with the industry’s most innovative automation technology for loading, unloading and part separation.

Salvagnini fiber laser cutters. Cutting edge technology. Lowest operating costs. Production-proven automation.

Salvagnini fiber laser cutters. The first. And the best.

worst fiber

1997

1998 2000 2002

2008 2010 2011

www.salvagnini.com

First “no teach” robots for parts handling with panel benders

First panel bender with zero set-up

Creation of the Automated Job Shop

First automated, robotic bending cell with off-line programming

First fiber laser cutter, the L1Xe

First punch-laser to use fiber optic technology – SL4

First lasers designed exclusively for fiber optic technology – the L3 & L5