Page 18 - MetalForming November 2012

P. 18

Maximizing

Your Laser’s

Productivity

During the last

two decades,

lasers have

become a critical tool

to help manufactur-

ers deal with a rapid-

ly evolving environ-

ment, one that has

driven the metal-

forming and fabricat-

ing industry to new levels of lean and efficient production. State-of-the-art laser-cutting machines optimize effi- ciency by eliminating multiple setups required with other processes.

That efficiency optimization took a leap forward with the recent advent of automatic changeout of nozzles and cutting lenses, as well as the ability to detect when there is a problem with either the nozzle or lens and adjust the

Jason Hillenbrand is laser product manager, Amada America, Inc.; Dru Schwartz is assistant manager of Amada’s Laser Technical Center; and Ron Malinowski is an Amada laser solu- tion engineer at its Laser Technical Cen- ter; www.amada.com.

upon it. By tapping into some of the deeper application advantages of a laser, not only can metal- formers achieve bet- ter cut quality and faster turnaround, but they also can reduce process time

for downstream activities such as bend- ing, parts cleanup and separation.

When you hear the term “applica- tions,” you may think of cut condi- tions. This is common terminology used when fine-tuning cutting speeds, power and gas output to produce acceptable edge quality at the fastest rate possible. However, true applica- tions go beyond that into improving process times, and even developing techniques to streamline other process- es—value-added or nonvalue-added.

In this article we focus on two such techniques possible with some—not all—laser-cutting systems. They are based on the ability to create a beam with a fine spot size, and to precisely control the beam power output to, in

16 MetalForming/November 2012

www.metalformingmagazine.com

Here’s a few tips and tricks to extract the maximum amount of flexibility from your laser-cutting machines.

BY JASON HILLENBRAND, DRU SCHWARTZ AND RON MALINOWSKI

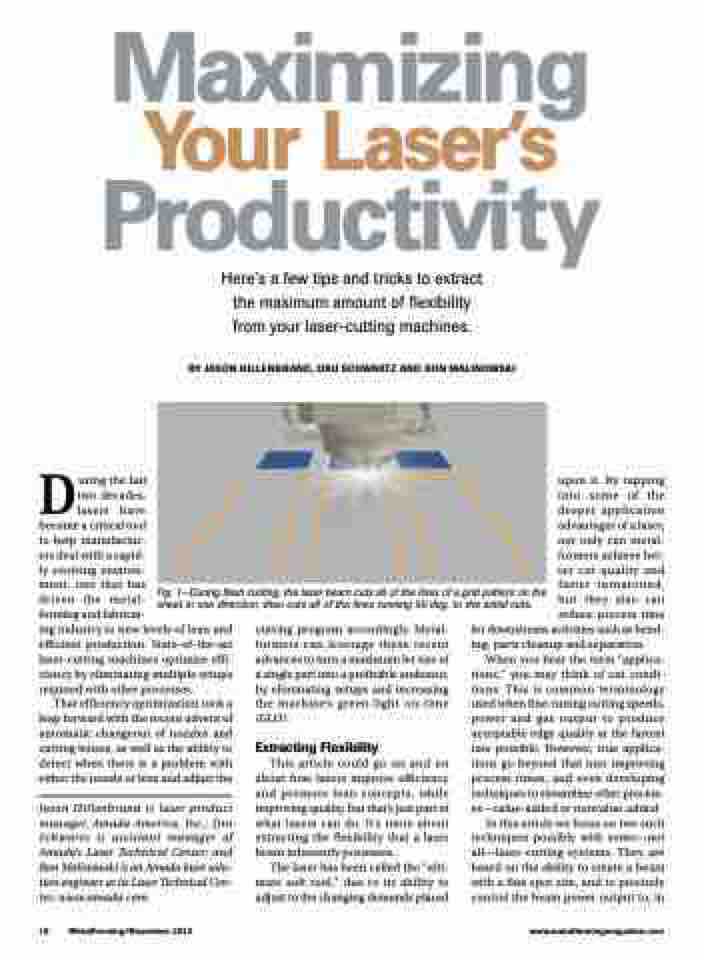

Fig. 1—During flash cutting, the laser beam cuts all of the lines of a grid pattern on the sheet in one direction, then cuts all of the lines running 90 deg. to the initial cuts.

cutting program accordingly. Metal- formers can leverage these recent advances to turn a maximum lot size of a single part into a profitable endeavor, by eliminating setups and increasing the machine’s green-light on-time (GLO).

Extracting Flexibility

This article could go on and on about how lasers improve efficiency and promote lean concepts, while improving quality, but that’s just part of what lasers can do. It’s more about extracting the flexibility that a laser beam inherently possesses.

The laser has been called the “ulti- mate soft tool,” due to its ability to adjust to the changing demands placed