Page 24 - MetalForming September 2012

P. 24

Just-in-Time

Nesting—

Concurrent

Engineering with

a Single Database

Sheetmetal-nesting software based on an expert system that enables concurrent engineering employs one database for both design and nesting. If designs change, new NC part programs are automatically recreated to match the new design, speeding the process and avoiding production of unusable parts.

BY MICHAEL LUNDY

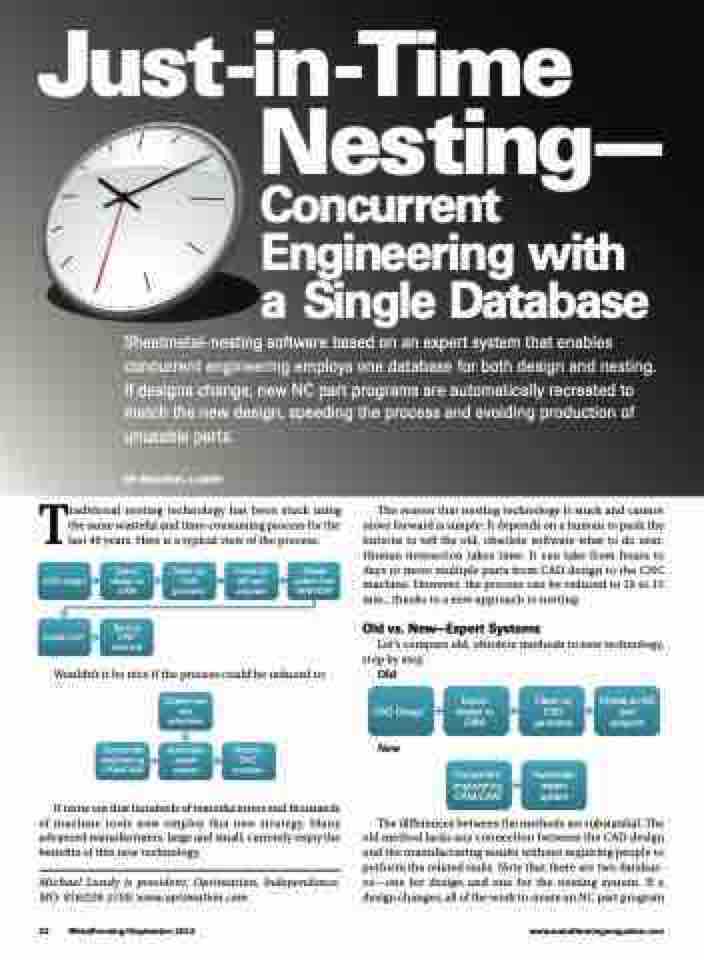

Traditional nesting technology has been stuck using The reason that nesting technology is stuck and cannot

the same wasteful and time-consuming process for the last 40 years. Here is a typical view of the process.

CAD design

Create nest

Export design to CAM

Clean up CAD geometry

Create an NC part program

Create orders from MRP/ERP

move forward is simple: It depends on a human to push the buttons to tell the old, obsolete software what to do next. Human interaction takes time. It can take from hours to days to move multiple parts from CAD design to the CNC machine. However, the process can be reduced to 10 to 15 min., thanks to a new approach to nesting.

Old vs. New—Expert Systems

Let’s compare old, obsolete methods to new technology, step by step.

Send to CNC machine

Wouldn’t it be nice if the process could be reduced to:

Old

CAD Design

New

CAM/CAM

Orders from any scheduler

Automatic expert system

Export design to CAM

Concurrent engineering CAM/CAM

Clean up CAD geometry

Automatic expert system

Create an NC part program

Concurrent engineering CAM/CAM

Send to CNC machine

It turns out that hundreds of manufacturers and thousands of machine tools now employ this new strategy. Many advanced manufacturers, large and small, currently enjoy the benefits of this new technology.

Michael Lundy is president, Optimation, Independence, MO: 816/228-2100; www.optimation.com.

The differences between the methods are substantial. The old method lacks any connection between the CAD design and the manufacturing results without requiring people to perform the related tasks. Note that there are two databas- es—one for design and one for the nesting system. If a design changes, all of the work to create an NC part program

22 MetalForming/September 2012

www.metalformingmagazine.com