Page 26 - MetalForming August 2012

P. 26

Take What You Know About

Stamping Presse

s

...and throw it out the window, because servo-driven mechanical presses are becoming the rule, not the exception. As a result, the rules of the stamping game have changed, forever.

BY BRAD F. KUVIN, EDITOR

The advent of servo-drive tech- nology in mechanical stamping presses has changed the rules of engagement between metalformers and their customers. Simply, early adopters of servo presses soon will—if they haven’t already—leapfrog their competitors in the race to gain new customers.

Throw everything you know—or think you know—about the ability to control a press’s slide motion and the types of metalforming operations that can be performed under ram out the window. With servo-drive presses, met-

alformers can program stroke and slide velocity in any imaginable combina- tion, to optimize performance for a given material and operation, whether it be blanking, coining or deep drawing. Servo motors, installed in place of the traditional flywheel/clutch drive train, allow the output shaft to be rotated in both directions. The press ram can stop precisely at any given position, and change speeds on a dime.

As explained in a recently pub- lished book from ASM Intl., by authors from Caterpillar Technical Center and The Ohio State University (Sheet Metal

Forming—Fundamentals, copyright 2012), metalforming-process design- ers around the world are being intro- duced to a whole new world of oppor- tunities:

• Dwell anywhere in the stroke, and at bottom-dead center (BDC), under full tonnage without energy loss.

• Reduce cutting speeds and snapthrough forces without compro- mising productivity.

• Control forming velocity to mini- mize friction and heat generation.

• Reduce impact speed and noise. • Make multiple hits on the work-

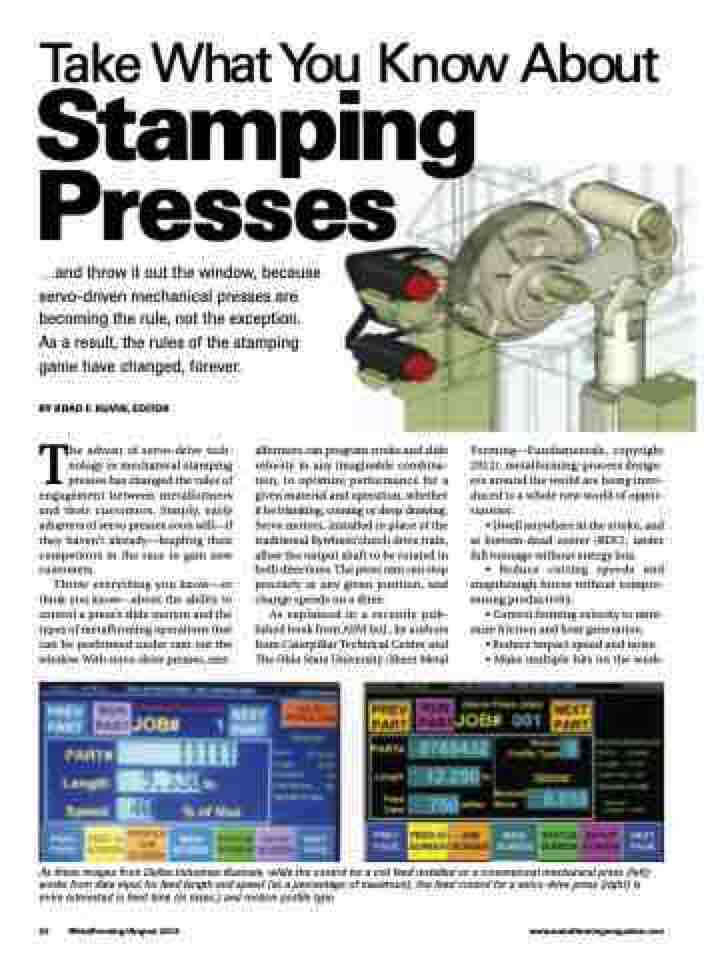

As these images from Dallas Industries illustrate, while the control for a coil feed installed on a conventional mechanical press (left) works from data input for feed length and speed (as a percentage of maximum), the feed control for a servo-drive press (right) is more interested in feed time (in msec.) and motion-profile type.

24 MetalForming/August 2012 www.metalformingmagazine.com