Page 14 - MetalForming August 2012

P. 14

Waterjet

Waterjet

Cutting

Cutting

Keeps the Work Flowing

Tru-Fab Technology is a “metal-fabrication shop with the ability to do a lot more,” according to company president (and welder/machine operator) John Stegh. Its pair of waterjet-cutting machines consistently leads customers to the door, so much so that a third machine may soon be on order.

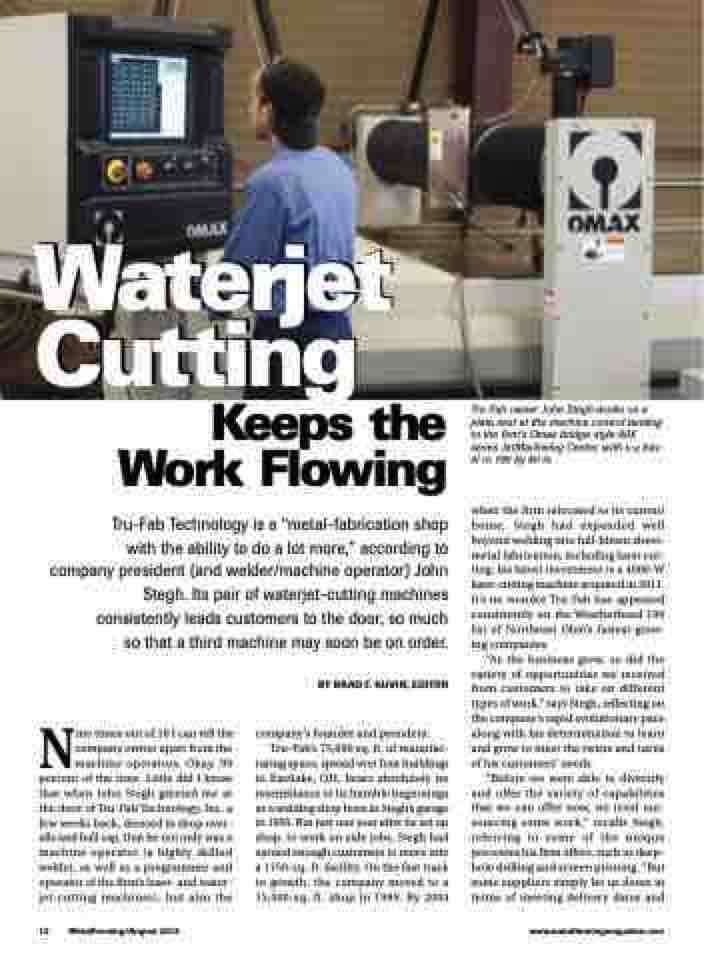

Tru-Fab owner John Stegh works on a plate nest at the machine control tending to the firm’s Omax bridge-style 80X series JetMachining Center, with x-y trav- el to 165 by 80 in.

when the firm relocated to its current home, Stegh had expanded well beyond welding into full-blown sheet- metal fabrication, including laser cut- ting; his latest investment is a 4000-W laser-cutting machine acquired in 2011. It’s no wonder Tru-Fab has appeared consistently on the Weatherhead 100 list of Northeast Ohio’s fastest-grow- ing companies.

“As the business grew, so did the variety of opportunities we received from customers to take on different types of work,” says Stegh, reflecting on the company’s rapid evolutionary pace along with his determination to learn and grow to meet the twists and turns of his customers’ needs.

“Before we were able to diversify and offer the variety of capabilities that we can offer now, we tried out- sourcing some work,” recalls Stegh, referring to some of the unique processes his firm offers, such as deep- hole drilling and screen printing. “But some suppliers simply let us down in terms of meeting delivery dates and

Nine times out of 10 I can tell the company owner apart from the machine operators. Okay, 99 percent of the time. Little did I know that when John Stegh greeted me at the door of Tru-Fab Technology, Inc. a few weeks back, dressed in shop over- alls and ball cap, that he not only was a machine operator (a highly skilled welder, as well as a programmer and operator of the firm’s laser- and water- jet-cutting machines), but also the

BY BRAD F. KUVIN, EDITOR

company’s founder and president. Tru-Fab’s 75,000 sq. ft. of manufac- turing space, spread over four buildings in Eastlake, OH, bears absolutely no resemblance to its humble beginnings as a welding shop born in Stegh’s garage in 1995. But just one year after he set up shop, to work on side jobs, Stegh had earned enough customers to move into a 1750-sq.-ft. facility. On the fast track to growth, the company moved to a 15,000-sq.-ft. shop in 1999. By 2004

12 MetalForming/August 2012

www.metalformingmagazine.com