Page 44 - MetalForming June 2012

P. 44

Tooling Technology

From CAD Drawing to Workable Die

Technology Keeps Improving

As die designers continue the transfer from 2D to 3D design while implementing integrated tool manufacture, software suppliers have delivered products with easier-to-use interfaces and robust simulation packages.

BY LOUIS A. KREN, CONTRIBUTING EDITOR

Not long ago, the path from part drawing to reli- able quote was quite intensive; tying up highly paid top techni- cal staff for work that most likely would never bring a contract. Going the distance—turning that quote into work- able production tooling —often was a lengthy and difficult task. That meant high costs and wasteful trial and error as tools entered the press and, until the tooling was perfected, scrap came out.

Today, the market

provides software that

runs the gamut—from simplified pro- grams that assist non-engineers with supplying timely quotes, to entire soft- ware suites with powerful solvers. These programs not only churn out accurate quotes in short order, but also carry the brains and number-crunch-

Forming magazine event held May 30-31 in Detroit. We’ve also tapped the expertise of Pete Ulintz, author of the monthly MetalForming Tooling By Design column. Here are their takes on recent soft- ware advancements and their impact on metal- formers.

Simplified Interfaces, Improved Integration Die design and simu- lation software bundles into an integrated pack- age that includes mod- ules for quoting, strip lay- out, die build and CNC programming, allowing users to employ the soft- ware from bid through part produc- tion. Or, individual modules can be used to augment whatever a designer/ builder already has in place. In addi- tion, you can find software that pro- vides some 3D CAD power to allow nontechnical employees to assist with

42 MetalForming/June 2012

www.metalformingmagazine.com

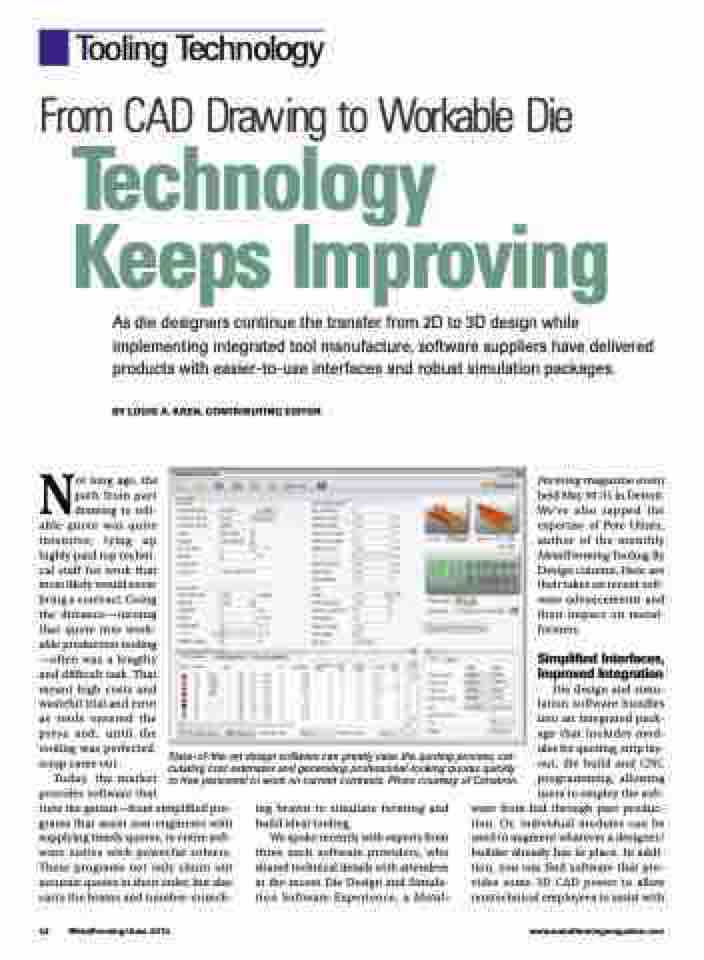

State-of-the-art design software can greatly ease the quoting process, cal- culating cost estimates and generating professional-looking quotes quickly to free personnel to work on current contracts. Photo courtesy of Cimatron.

ing brawn to simulate forming and build ideal tooling.

We spoke recently with experts from three such software providers, who shared technical details with attendees at the recent Die Design and Simula- tion Software Experience, a Metal-