Page 38 - MetalForming February 2012

P. 38

Tooling Technology

Expected: 100-Percent

Accurate Die Designs

It’s a new era of die design and development at world-renowned Autodie, Grand Rapids, MI, where new ownership is consistently investing in new technology and training. The goal: To advance the company’s future as a leading, global supplier of stamp- ing-die engineering and manufacturing services.

Slated to close its doors in 2006, after having enjoyed 40 years of success specializing in large dies for the auto- motive industry, for body sides and Class A surfaces primarily, Autodie has been reenergized and resurrected. While the firm’s success once rode on

Committed to the development of manufacturable solids,

Autodie has spent the last 4 yr. focusing on ensuring

that all of its die designs are 100 percent machinable.

Now, CAD and CAM models are one in the same.

BY BRAD F. KUVIN, EDITOR

the back of a single customer, Chrysler, it now works for several automotive OEMs and has nearly doubled its annu- al revenue since 2007.

At the heart of this resurrection is what company vice president and COO David Darling calls a new concept in die design—manufacturable solids. “We’re zealots in terms of die develop-

ment and simulation,” says Darling. “We are absolutely committed to pro- viding our die-manufacturing group with 100-percent NC-ready die designs. That means closing the gap between those making our solid models and those preparing them for machining, with the understanding that we expect our die designs to be 100 percent accu- rate for construction, fastening and machining. Failure to demand this level of accuracy amounts to generating rework and waste.”

Paving the Road to Manufacturable Solids

Technology was, unfortunately, not always a focus at Autodie, Darling admits. In the late 1990s and early part of the new century, management treat- ed technology as a commodity, as opposed to a core part of its business. As did numerous others in the North American automotive-industry supply chain, Autodie also outsourced die making to low-cost countries. “We fol- lowed that line of thinking until 2006,” Darling says.

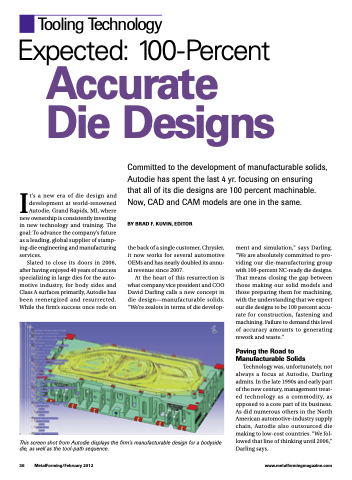

This screen shot from Autodie displays the firm’s manufacturable design for a bodyside die, as well as the tool-path sequence.

36 MetalForming/February 2012

www.metalformingmagazine.com